Durable flame-retardant non-ironing finishing liquid and finishing method

A non-iron finishing and durable flame-retardant technology, which is applied in fiber treatment, textiles, papermaking, plant fibers, etc., can solve the problems of poor washability and achieve the goal of improving washability, flame retardancy, and non-ironing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

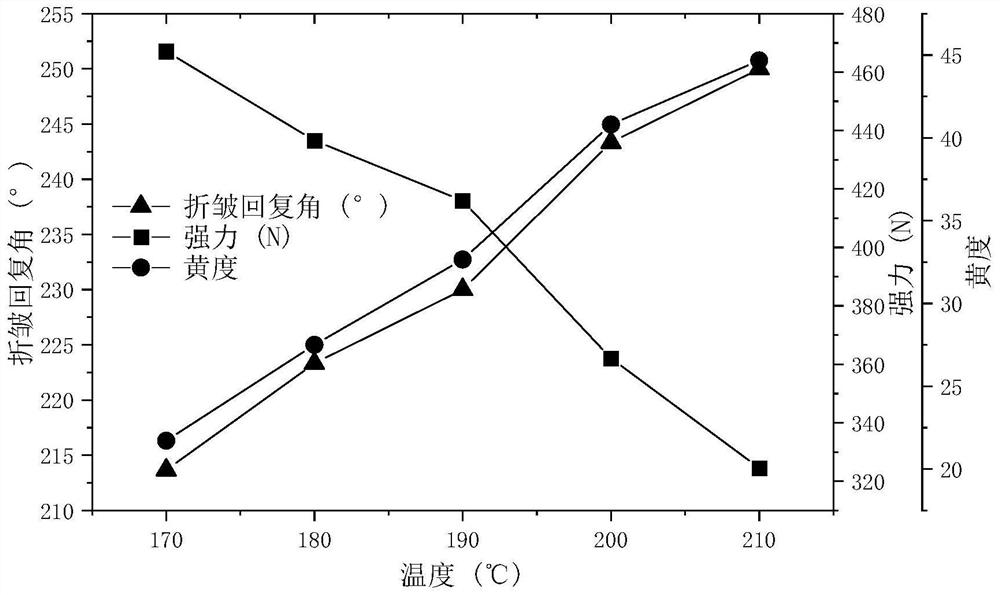

Embodiment 1

[0038] The present invention proposes a durable flame-retardant non-ironing finishing liquid and a finishing method, and the specific steps are as follows:

[0039] Select pure cotton plain weave fabric, which is pretreated by desizing and bleaching, with a linear density of 7.29tex×2×7.29tex×2, a warp and weft density of 472 threads / 10cm×276 threads / 10cm, and an area density of 110g / m2. The breaking strength was 591 N, the crease recovery angle was 156° and the whiteness was 72.3.

[0040] (1) The preparation process of the finishing solution: Diethylene triamine pentamethylene phosphoric acid 20g / L, ammonium dihydrogen phosphate 40g / L, dicyandiamide 40g / L, urea 20g / L, penetrant 2g / L, softener 20g / L was prepared to obtain the finishing solution.

[0041] (2) Padding process: arrange the pure cotton plain weave in (1) finishing solution for two dipping and two rolling, and the excess rolling rate is 80%.

[0042] (3) Post-treatment process: After the pure cotton plain cloth ...

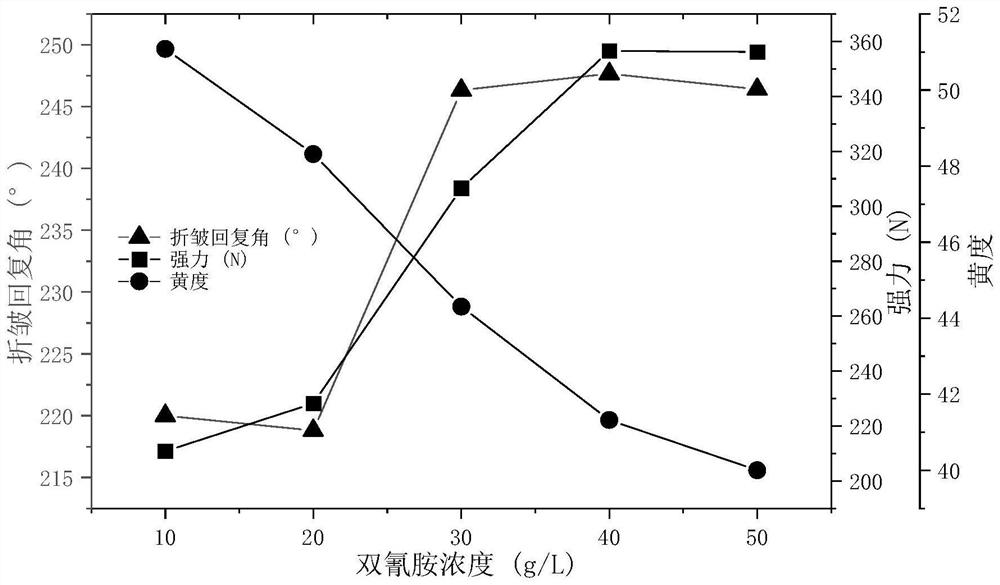

Embodiment 2

[0046] The present invention proposes a durable flame-retardant non-ironing finishing liquid and a finishing method, and the specific steps are as follows:

[0047] Select pure cotton plain weave fabric, which is pretreated by desizing and bleaching, with a linear density of 7.29tex×2×7.29tex×2, a warp and weft density of 472 threads / 10cm×276 threads / 10cm, and an area density of 110g / m2. The breaking strength was 591 N, the wrinkle recovery angle was 156° and the whiteness was 72.3.

[0048] (1) The preparation process of the finishing solution: 20g / L of diethylenetriaminepentamethylene phosphoric acid, 40g / L of ammonium dihydrogen phosphate, xg / L of dicyandiamide, 20g / L of urea, 2g / L of penetrant, and 20g of softener / L;

[0049] (2) Padding process: arrange the pure cotton plain weave in (1) finishing solution for two dipping and two rolling, and the excess rolling rate is 80%.

[0050] (3) Post-treatment process: After the pure cotton plain cloth is soaked with the finish...

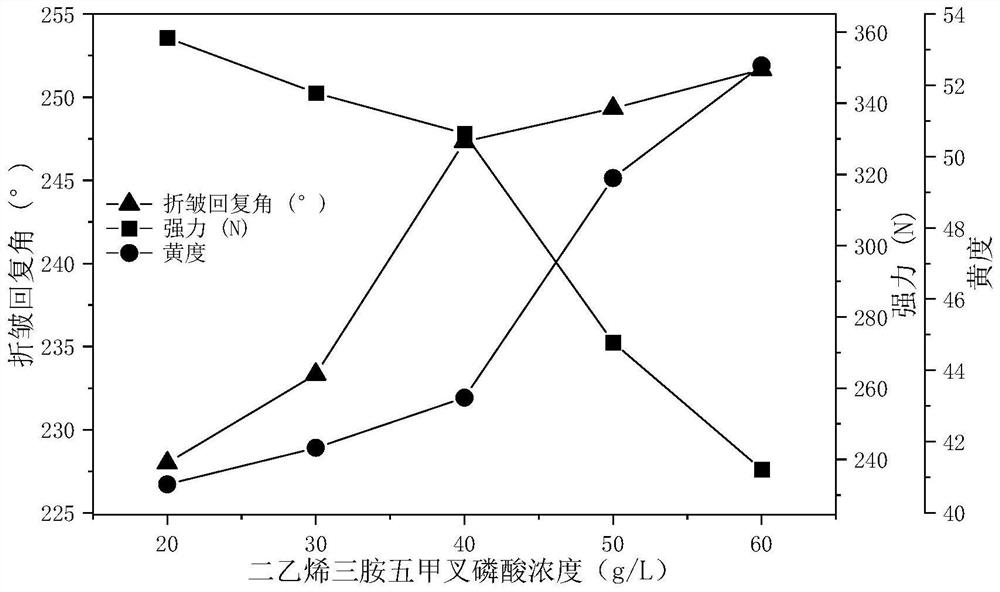

Embodiment 3

[0053]The present invention proposes a durable flame-retardant non-ironing finishing liquid and a finishing method, and the specific steps are as follows:

[0054] Select pure cotton plain weave fabric, which is pretreated by desizing and bleaching, with a linear density of 7.29tex×2×7.29tex×2, a warp and weft density of 472 threads / 10cm×276 threads / 10cm, and an area density of 110g / m2. The breaking strength was 591 N, the crease recovery angle was 156° and the whiteness was 72.3.

[0055] (1) The preparation process of the finishing liquid: Diethylenetriaminepentamethylene phosphoric acid xg / L, ammonium dihydrogen phosphate 40g / L, dicyandiamide 40g / L, urea 20g / L, penetrant 2g / L, softener 20g / L was prepared to obtain the finishing solution.

[0056] (2) Padding process: arrange the pure cotton plain weave in (1) finishing solution for two dipping and two rolling, and the excess rolling rate is 80%.

[0057] (3) Post-treatment process: After the pure cotton plain cloth is soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Wrinkle recovery angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com