Seamless welding building decoration robot

A seamless welding and robot technology, applied in the field of floor welding, can solve problems such as unsatisfactory welding effect, and achieve the effect of increasing welding flexibility, improving use effect, and avoiding welding deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

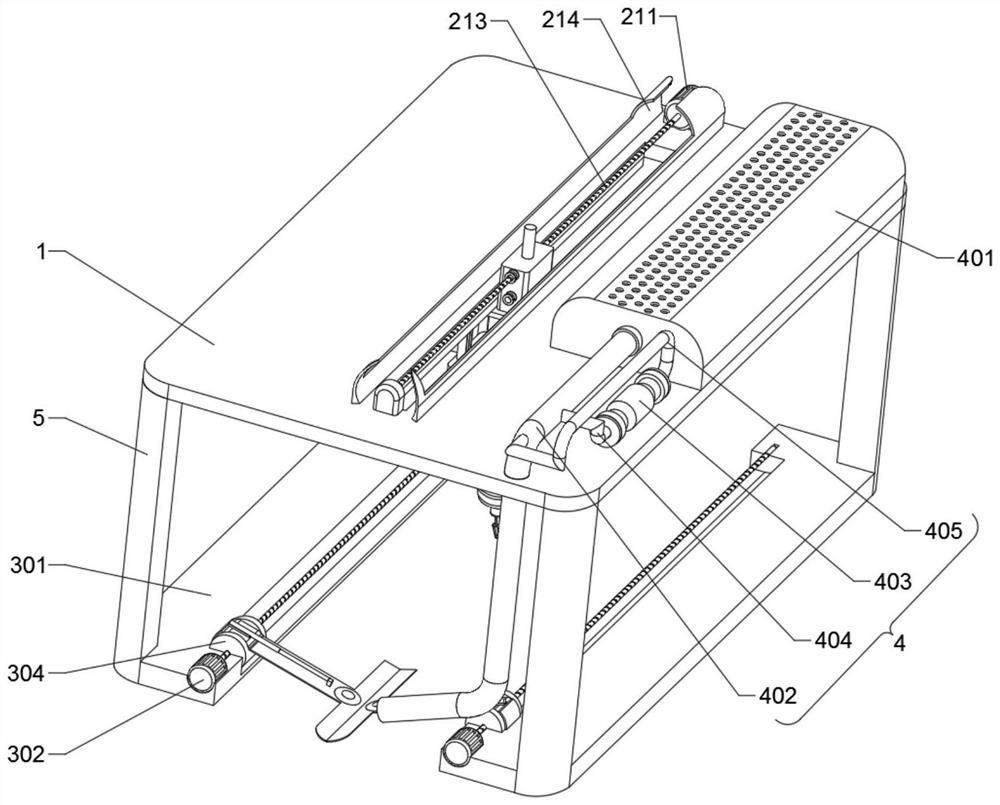

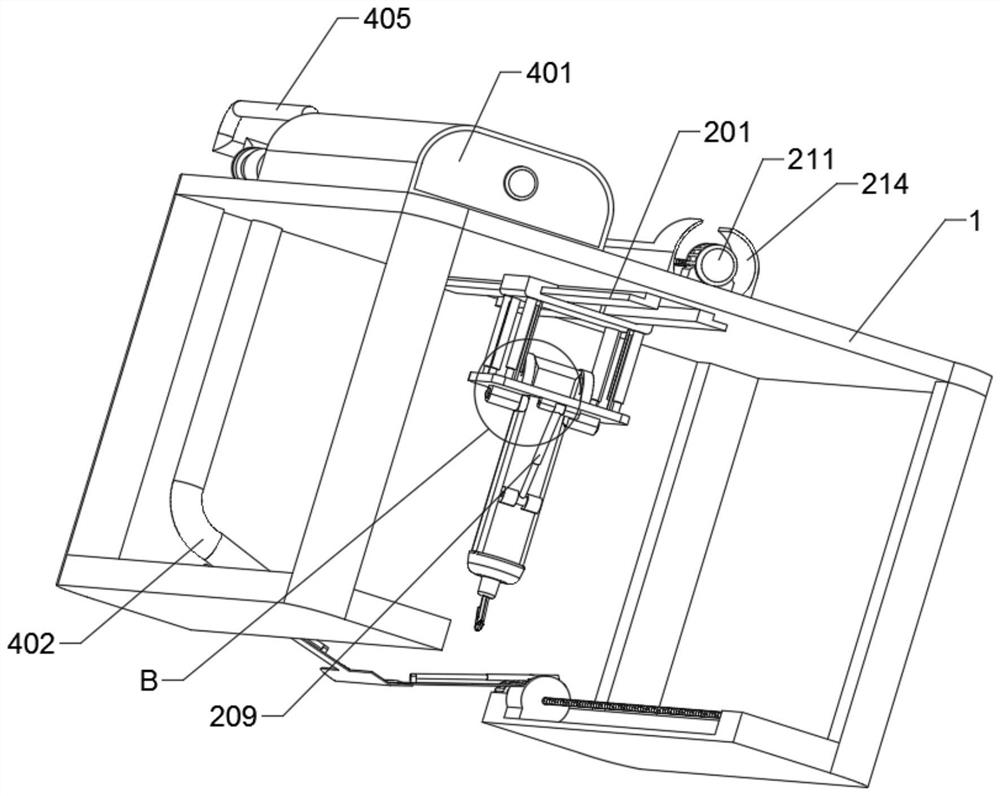

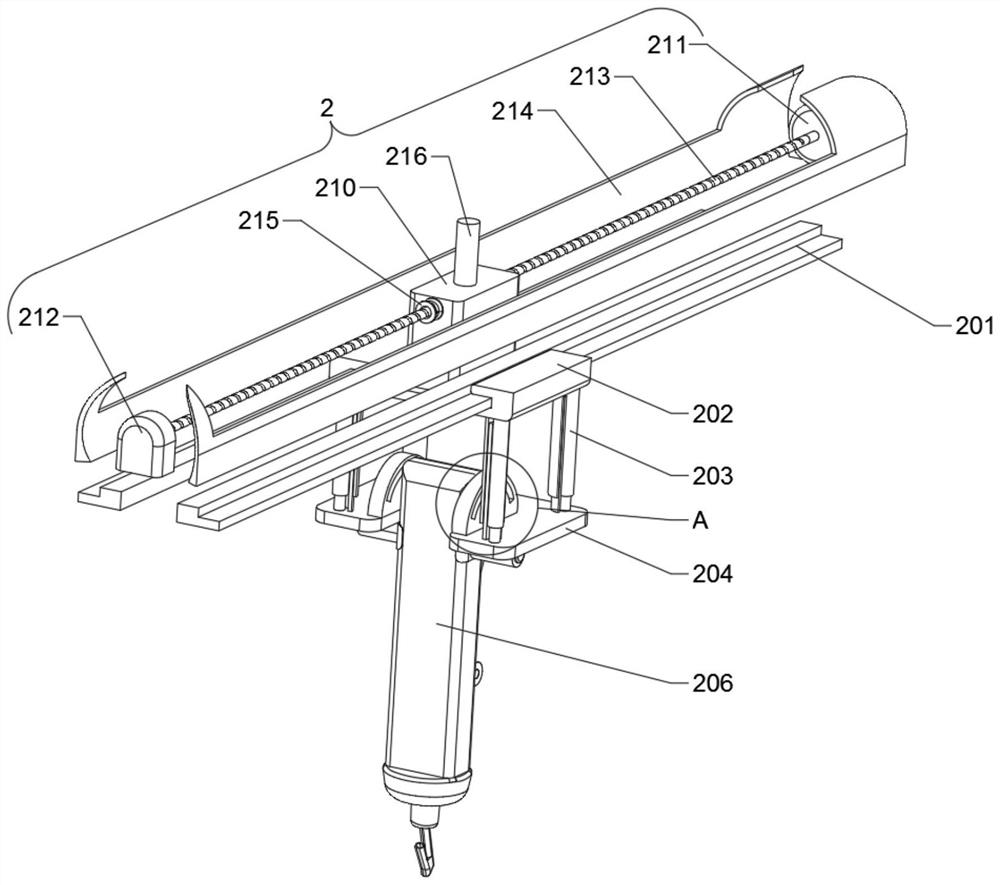

[0042] Such as Figure 1-Figure 9 As shown, a seamless welding building decoration robot of this embodiment includes a support plate 1, and a welding mechanism 2 is arranged on the support plate 1. Specifically, the welding mechanism 2 includes a welding torch 206 located below the support plate 1, and the support plate 1 above is provided with a translation unit for driving the welding torch 206 to move back and forth, and below the support plate 1 is provided with a lifting unit for driving the welding torch 206 up and down, and a rotation unit for driving the welding torch 206 to rotate.

[0043] Specifically, the translation unit includes a first motor 211 and a first threaded rod 213 arranged on the support plate 1, the first threaded rod 213 is fitted with a first slider 210, and the first slider 210 passes through the support plate 1 and the bottom is provided with a sliding plate 202 that slides and fits with the limit plates 201 on both sides of the through groove. Th...

Embodiment 2

[0049] A seamless welding building decoration robot of this embodiment is basically the same as that of Embodiment 1. Furthermore, this embodiment also includes a slotting mechanism 3, such as figure 1 , Figure 4 and Figure 5 As shown, both sides of the bottom of the support plate 1 are respectively connected with a bottom plate 301 through the support legs 5, and the slotting mechanism 3 includes a second motor 302 and a second threaded rod 303 arranged on the bottom plate 301 on each side, and the second threaded rod 303 is equipped with a There is a second slider 304, and the second motor 302 is used to drive the second slider 304 to reciprocate; the top of the second slider 304 is provided with a fixed plate 305, and the fixed plate 305 is slidingly fitted with an adjustment plate 306, and the second motor The telescoping rod 307 is installed on the fixing plate 305 and the telescoping end is connected with the adjusting plate 306 , the adjusting plates 306 on both side...

Embodiment 3

[0053] A seamless welding building decoration robot in this embodiment is basically the same as the above embodiment, furthermore, this embodiment also includes a cleaning mechanism 4, and the cleaning mechanism 4 includes a storage box 401 and a fan 403 arranged on the support plate 1 The outer side of the storage box 401 is connected with a hollow tube 402, and the hollow tube 402 extends toward the bottom of the support plate 1, and specifically extends to the position where the cutting pieces 308 on both sides of the slotting mechanism 3 are spliced together; the air inlet of the fan 403 passes through the first The communicating pipe 404 communicates with the hollow pipe 402 , the air outlet of the fan 403 communicates with the hollow pipe 402 through the second communicating pipe 405 , and a filter 406 is installed on the inner wall of the hollow pipe 402 . Moreover, the position of the connection point between the first communication pipe 404 and the hollow pipe 402 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com