Degradable plastic bag continuous blow molding mold and use method

A blow molding, plastic bag technology, applied in the field of plastic bags, can solve the problems of plastic bag adhesion, reduce plastic bag quality, plastic bag rupture, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

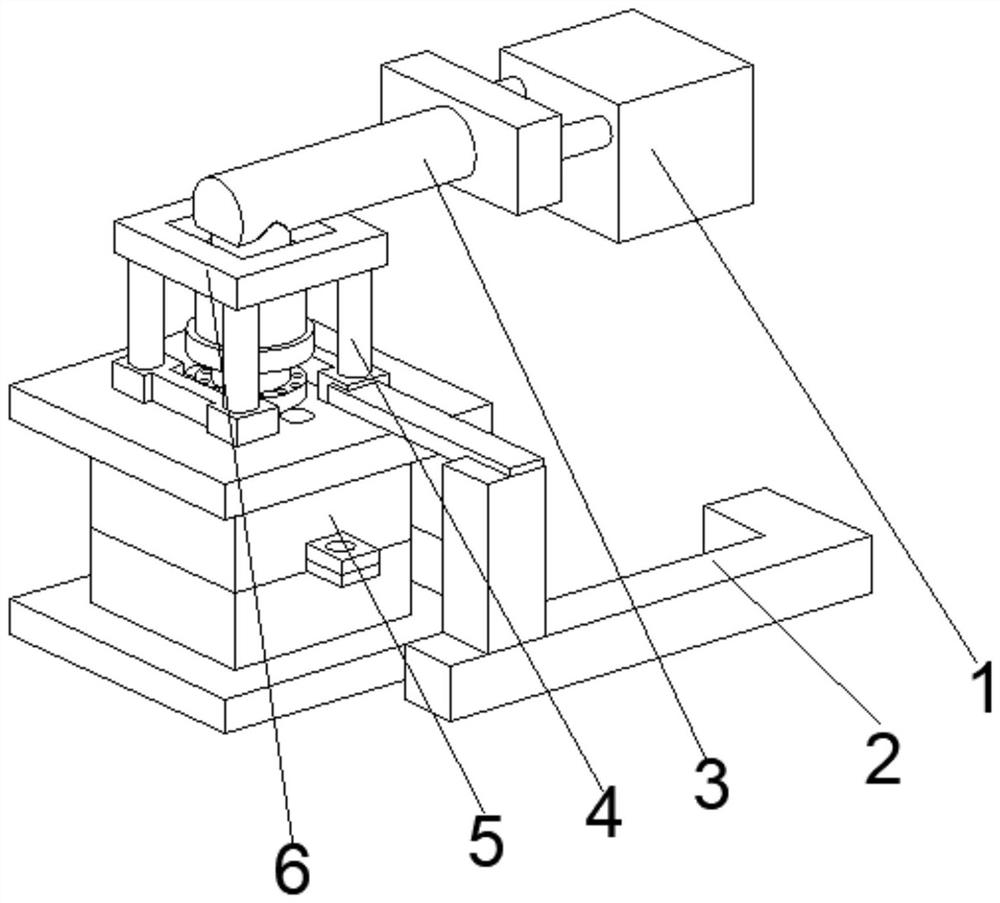

[0042] see Figure 1-6 , The present invention provides a technical solution: a continuous blow molding mold for degradable plastic bags, including a limit plate 6, the bottom of the limit plate 6 is fixedly connected with a positioning column 4, and the bottom of the positioning column 4 is fixedly connected There is a blow molding device 5. The top middle position of the blow molding device 5 penetrates the limit plate 6 and extends to the outside of the limit plate 6. The top of the blow molding device 5 is connected with an air guide hose 3, and the right end of the air guide hose 3 is connected. The airflow collection box 1 is communicated, and the airflow collection box 1 is connected with a plurality of air supply parts, so that the air supply parts can continuously convey the wind force inside the airflow collection box 1, and the air flow collection box 1 and the air guide hose 3 are connected. It is connected to facilitate the blow molding of plastic bags in time, wh...

Embodiment 2

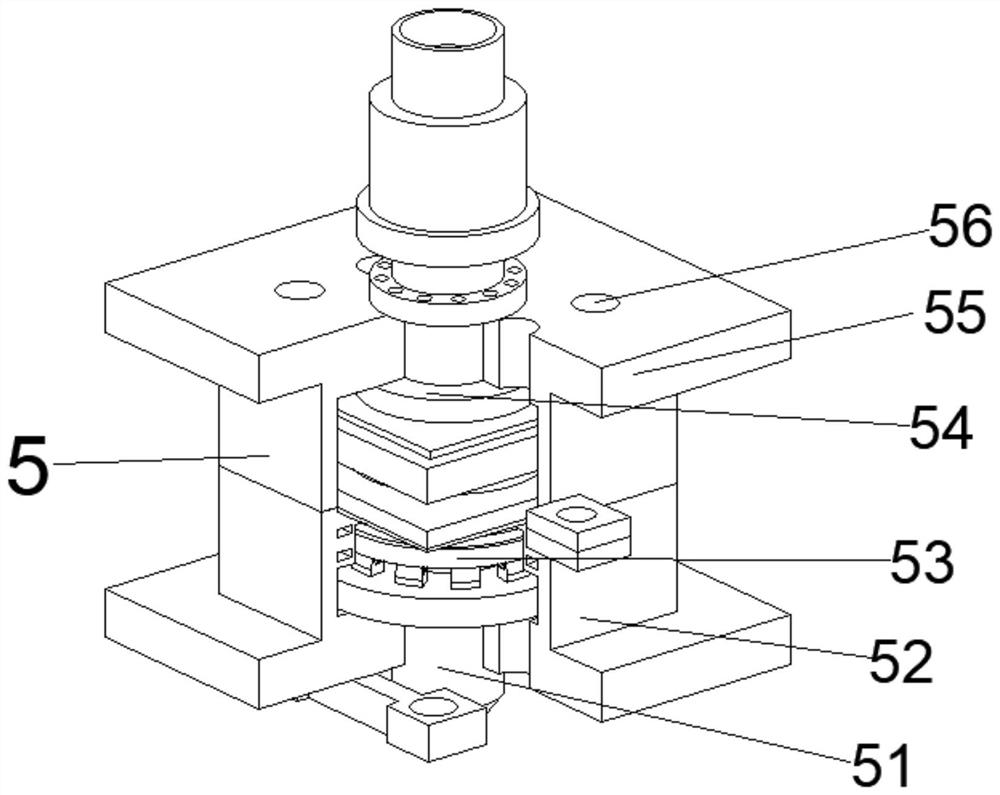

[0049] see Figure 1-7 , On the basis of Embodiment 1, the present invention provides a technical solution: a method for using a continuous blow molding mold for degradable plastic bags, step 1: Connect the airflow collection box 1 with the air guide hose 3, so that The airflow collection box 1 is connected with two air supply parts to continuously supply air to the inside of the air guide hose 3, and the cold water circulation pipe 2 is used to inject cold water into the blow molding device 5 to quickly cool down the plastic bags that appear;

[0050] Step 2: The plastic bag is blown through the processing cavity generated by the upper die base 55 and the lower die base 52. With the injection of cold air from the water injection port 56 into the upper die base 55, the blow molding head 51 and the auxiliary device 53 are carried out. communicate, and communicate the auxiliary device 53 with the communication device 54, so that the air flow enters the blow molding head 51 to bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com