Prefabricated composite floor slab steel mesh framework production equipment and production process

A technology of production equipment and laminated floor slabs, applied in the fields of wire mesh, wire processing, household appliances, etc., can solve the problems of a large number of production workers, inconvenient equipment debugging, increased material storage, and handling, etc., to achieve production rhythm and high cohesion , avoid the accumulation of semi-finished materials, and improve the effect of lean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

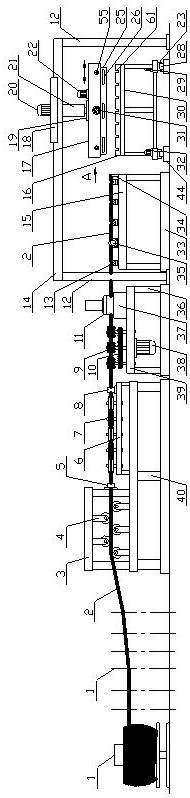

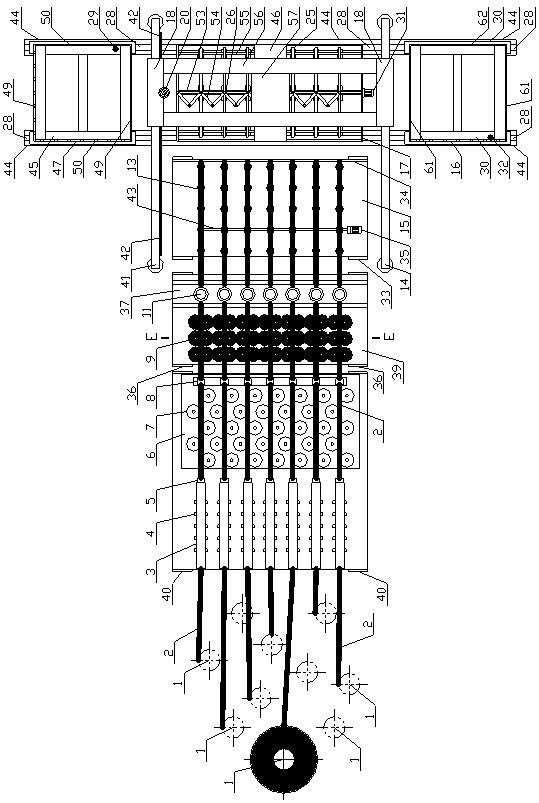

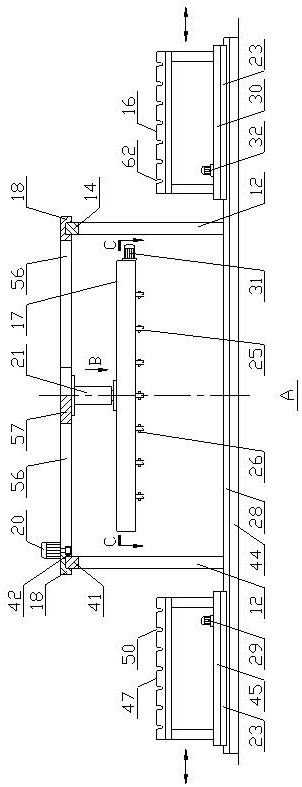

[0080] Such as Figure 1~3 As shown, coiled steel bars 2 are placed on the pay-off reel 1, and the coiled steel bars 2 are straightened after passing through the vertical straightening roller group 4, the first guide 5, the horizontal straightening roller group 7, and the second guide 8 . The vertical alignment roller group 4 is installed on the vertical alignment system frame 3, the horizontal alignment roller group 7 is installed on the horizontal alignment system frame 6; the vertical alignment system frame 3 and the horizontal alignment system frame 6 are installed on the alignment system On the platform 40; the first guide 5 is installed on the outlet end of the vertical alignment system frame 3, and is roughly collinear with the center of the vertical alignment roller group 4; the second guide 8 is installed on the outlet of the horizontal alignment system frame 6 end, and roughly collinear with the center of the horizontal straightening roller set 7. The first guide 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com