Nano-cellulose hydrogel film with efficient separation function as well as preparation method and application of nano-cellulose hydrogel film

A technology of nanocellulose and hydrogel, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as bridging, incomplete filtration of nanoparticles, and easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the nanocellulose hydrogel film described in the above technical scheme, comprising the following steps:

[0032] (1) wood powder, sodium chlorite, glacial acetic acid and water are mixed, carry out the first oxidation treatment, obtain the cellulose;

[0033] (2) Mix the cellulose, inorganic alkali and water, and perform the first alkali treatment to obtain primary purified microfibers;

[0034] (3) Mix the primary purified microfiber, sodium chlorite, glacial acetic acid and water, and perform a second oxidation treatment to obtain secondary purified cellulose;

[0035] (4) mixing the secondary purified microfibers, inorganic alkali and water, and performing a second alkali treatment to obtain purified cellulose;

[0036] (5) mixing the purified cellulose with water, and ultrasonicating to obtain a nanocellulose suspension;

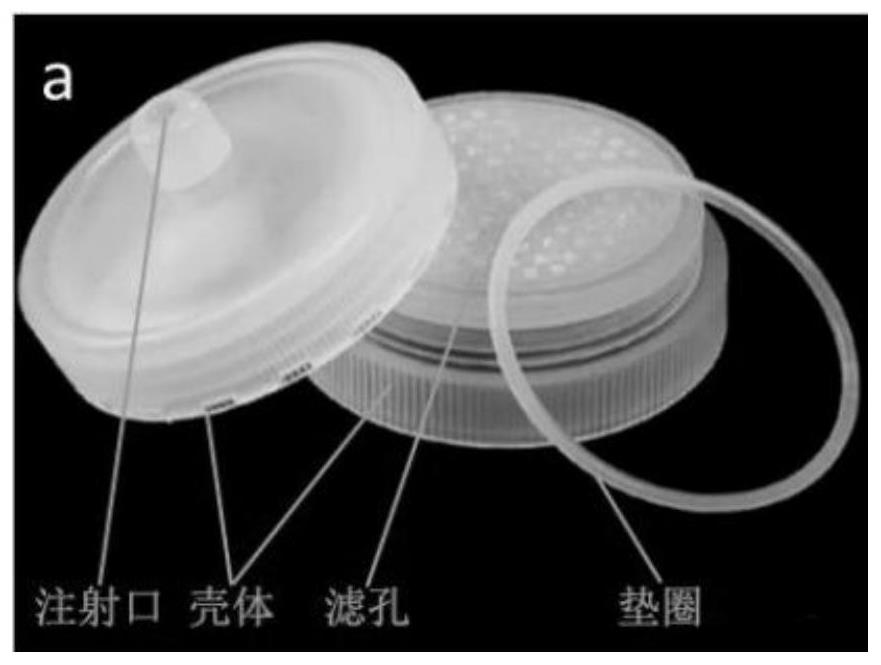

[0037] (6) Injecting the nanocellulose suspension under pressure to obtain the nan...

Embodiment 1

[0067] Sieve 30g of poplar wood powder with a 60-mesh screen and pour it into a beaker, add 1500g of distilled water, 15g of sodium chlorite and 3mL of glacial acetic acid, and oxidize it in a water bath at 75°C for 5h, adding chlorite every 1h during the process Sodium nitrate 15g, glacial acetic acid 3mL, a total of 5 times, to obtain comprehensive cellulose.

[0068] After washing 15g of cellulose to neutrality with water, mix it with 40g of potassium hydroxide solution with a concentration of 5mol / L, and treat it with alkali in a water bath at 75°C for 2h to obtain primary purified microfibers.

[0069] 15g of primary purified microfibers, 15g of sodium chlorite, 1500mL of glacial acetic acid and 3mL of water were oxidized in a water bath at 75°C for 2 hours, washed until neutral, and then treated with alkali to obtain purified cellulose;

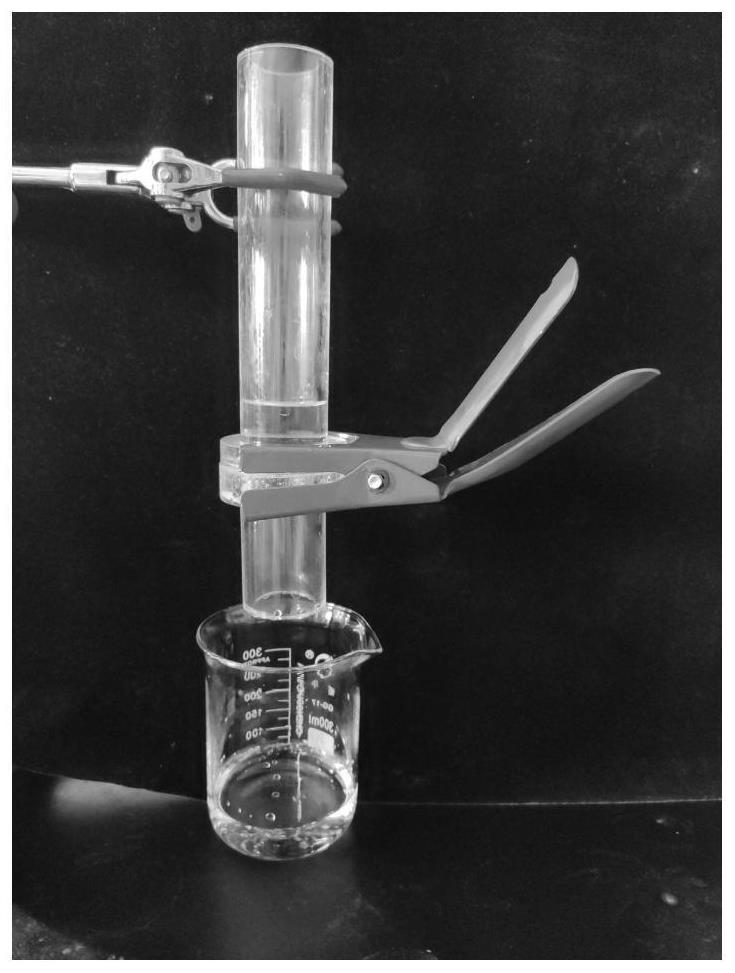

[0070] The purified cellulose was mixed with water, and then it was sonicated with an ultrasonic cell pulverizer with an ultrasonic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com