Novel apron conveyor slag removal device

A conveyor and slat technology, applied in the field of garbage disposal equipment, can solve the problems of high noise, waste of energy, and insufficient rhythm, and achieve the effects of reducing noise, reducing power consumption, and optimizing space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

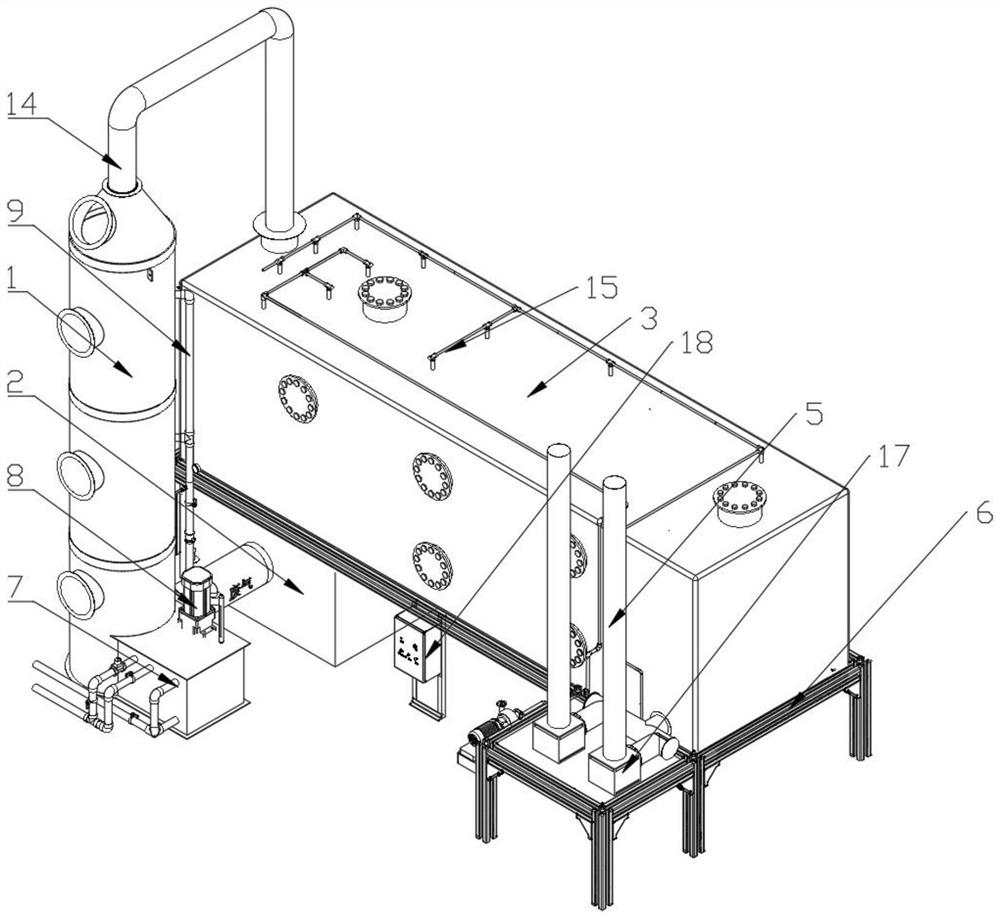

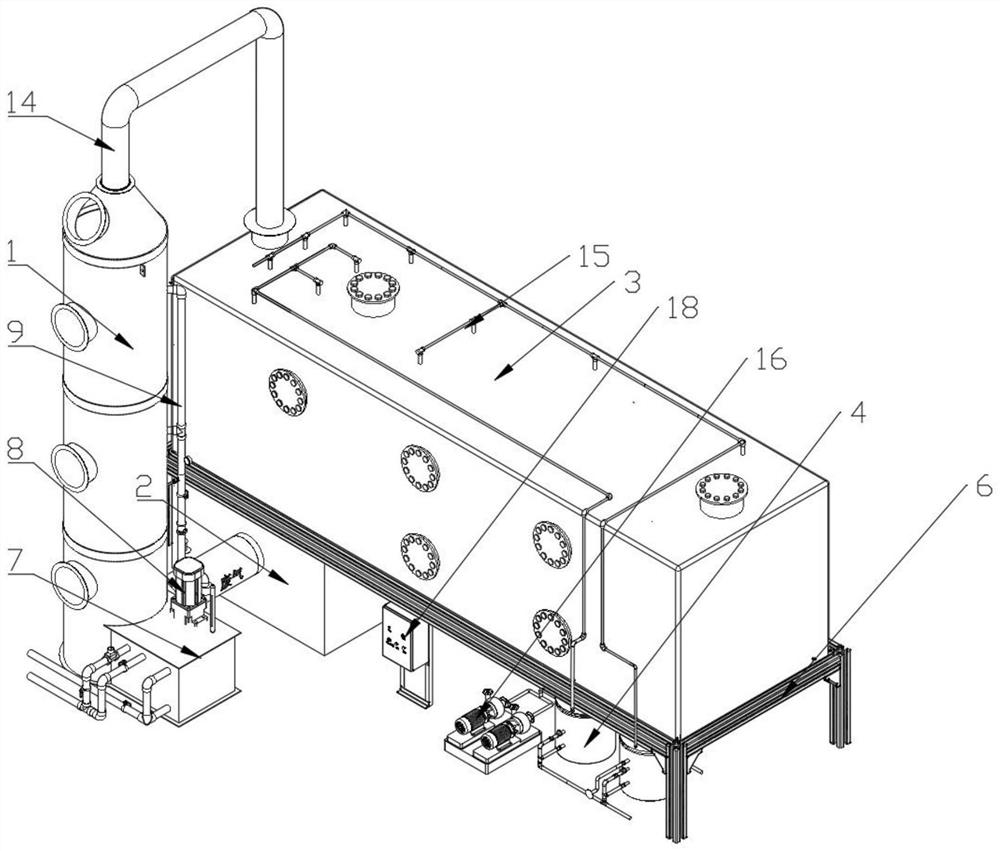

Image

Examples

Embodiment 1

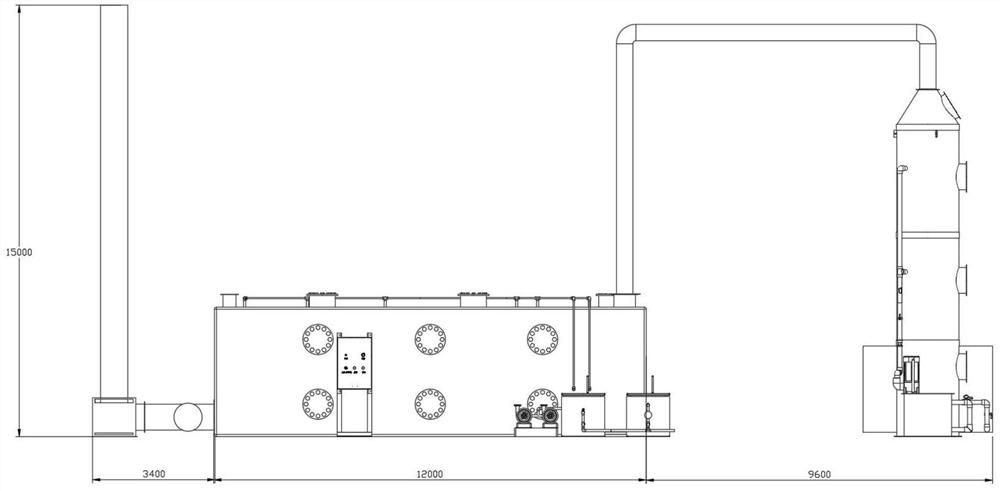

[0029] Use the following equipment to build deodorization equipment, and compare it with the occupied space of existing deodorization equipment:

[0030] Filter box specification: 3000 width * 3000 height * 12000 length (mm), washing tower specification: 1500 diameter * 9000 height (mm), silencer box specification: 1000 width, 1000 height, 1000 length (mm).

[0031] Such as image 3 , Figure 4 As shown, in the traditional construction method, the overall length needs to be 25000 mm, while the arrangement method of the present invention occupies only 12800 mm in length, saving more than double the length.

Embodiment 2

[0033] On the basis of Example 1, confirm that the height of the base frame is 3000mm, the processing air volume of the deodorization box is 1500m3 / h, the air pressure is 1500-2500Pa (as PJ-1500 deodorization box), and the exhaust height requirement is 15000mm ("Stink Pollutant Discharge Standard "GB14554-93),

[0034] To meet the above-mentioned air supply standard, the fans to be used at the washing tower are the same, both are TF-151B-3KW fans with a power of 3KW (performance 35000CMH*1500Pa), but since the exhaust pipe is elevated by 3000mm, the exhaust pipe Compared with the existing equipment, the TF-151B2.2KW fan with smaller power can be selected.

[0035] Due to the cover of the filter box, the load on the second liquid pump 16 is increased, but the flow rate of the 40FSB-25 type liquid pump used in the existing deodorization equipment is 500L / h, and the head is 20000mm, which fully meets the liquid supply after transformation. volume requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com