Method for preparing plant-based pure coconut milk yoghourt from tender coconut meat

A coconut meat and plant-based technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of inability to produce yogurt and achieve high acid bacteria content and good sensory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] When preparing the tender coconut meat powder, the homogeneous substance was cooled at 4°C, and subjected to quick-freezing treatment at -20°C, and then freeze-dried, and the freeze-dried substance was pulverized to obtain a powder;

[0030] The third step is to prepare the coconut water raw material first, then sterilize the coconut water, and finally put the lactic acid bacteria powder or liquid lactic acid bacteria into the above-mentioned sterilized coconut water in an aseptic manner according to the requirements of the inoculation amount of the bacteria. When preparing the strain liquid, put lactic acid bacteria powder or liquid lactic acid bacteria into the above-mentioned sterilized coconut water in an aseptic manner according to the requirements of the inoculation amount of the bacteria, and cultivate them at 38°C-42°C for 24-48 hours to make the lactic acid bacteria If the concentration reaches 108cfu / mL and above, it can be used directly or stored at 4°C for no...

Embodiment 1

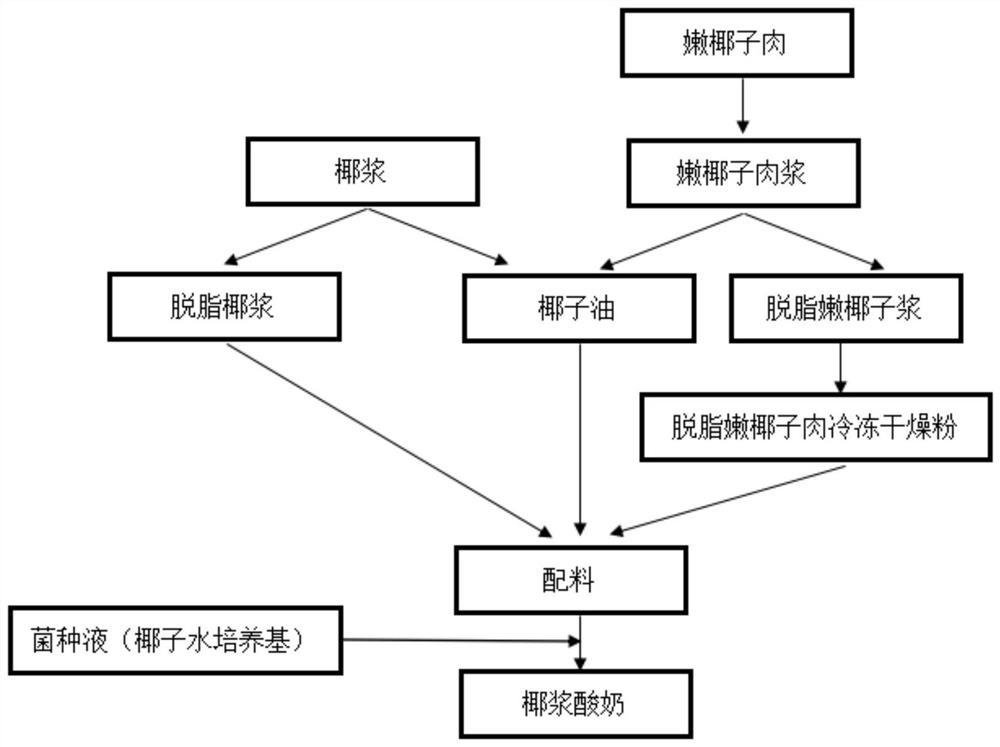

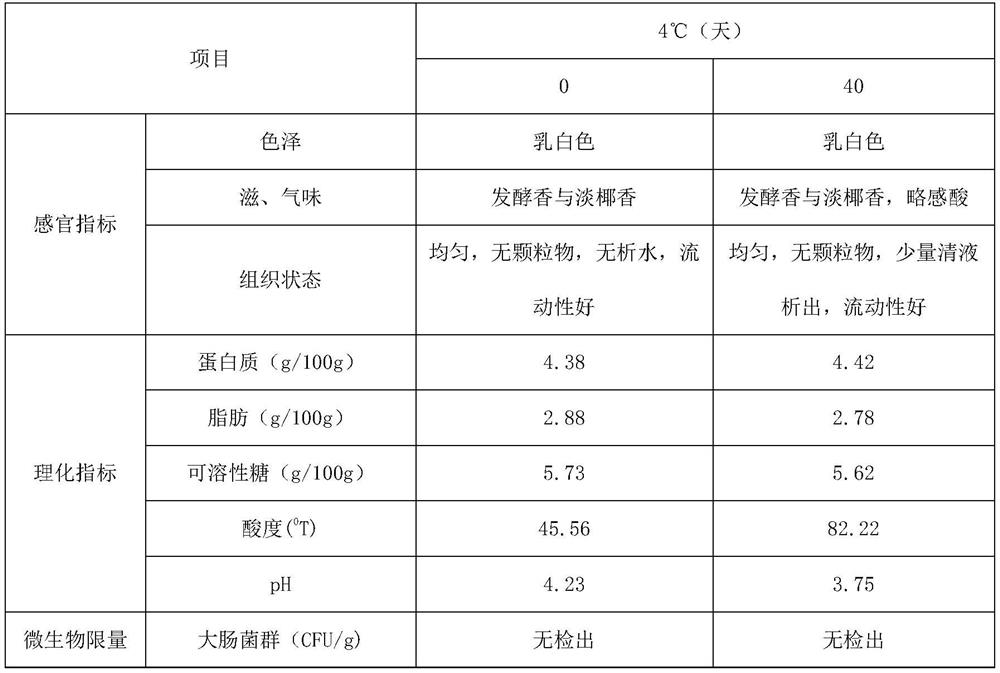

[0037] 100kg defatted coconut milk, add 3kg coconut oil (from figure 1 Coconut oil shown in ), heated to 60°C, homogenized once by 25Mpa, then added 1 kg of defatted tender coconut meat freeze-dried powder, stirred and heated to 70°C, maintained for 30 minutes, when cooled to 40°C, put in 2 Kilogram seed liquid (Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus), stirred at 40 rpm for one hour, stopped stirring, kept at 40°C, took a sample to measure after 10 hours, the pH was 4.2, and started stirring at this moment, at 40 After stirring for one hour at rpm, keep stirring and lower the temperature to 4°C, then aseptically dispense into sterile glass bottles, seal, store at 4°C, and take samples when it is just prepared and on the 40th day. Analyze the quality of coconut milk yoghurt.

[0038]

[0039]

Embodiment 2

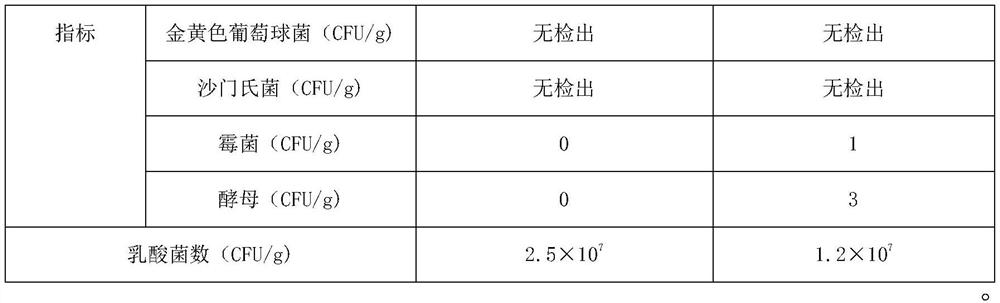

[0041] 100kg defatted coconut milk, add 3kg coconut oil (from figure 1 Coconut oil shown in ), heated to 65°C, homogenized once by 25Mpa, then added 3 kg of defatted tender coconut meat freeze-dried powder, stirred and heated to 75°C, maintained for 25 minutes, when cooled to 40°C, put in 3 Kilograms of seed liquid (Lactobacillus plantarum and Streptococcus thermophilus), stirred at 40 rpm for one hour, stopped stirring, maintained at 40°C, took a sample to measure after 10 hours, the pH was 4.4, started stirring at this time, and stirred at 40 rpm One hour later, keep stirring and cool down to 4°C, then aseptically dispense into sterile glass bottles, seal, store at 4°C, and take samples when it is just prepared and when it is 40 days old, and analyze the quality of the coconut milk yoghurt. quality.

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com