A kind of yoghurt and preparation method thereof

A technology of yogurt and lactic acid bacteria powder, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of inconvenient storage and carrying of yogurt, single nutritional components, etc., and achieve the prevention and treatment of osteoporosis, rich nutrition, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

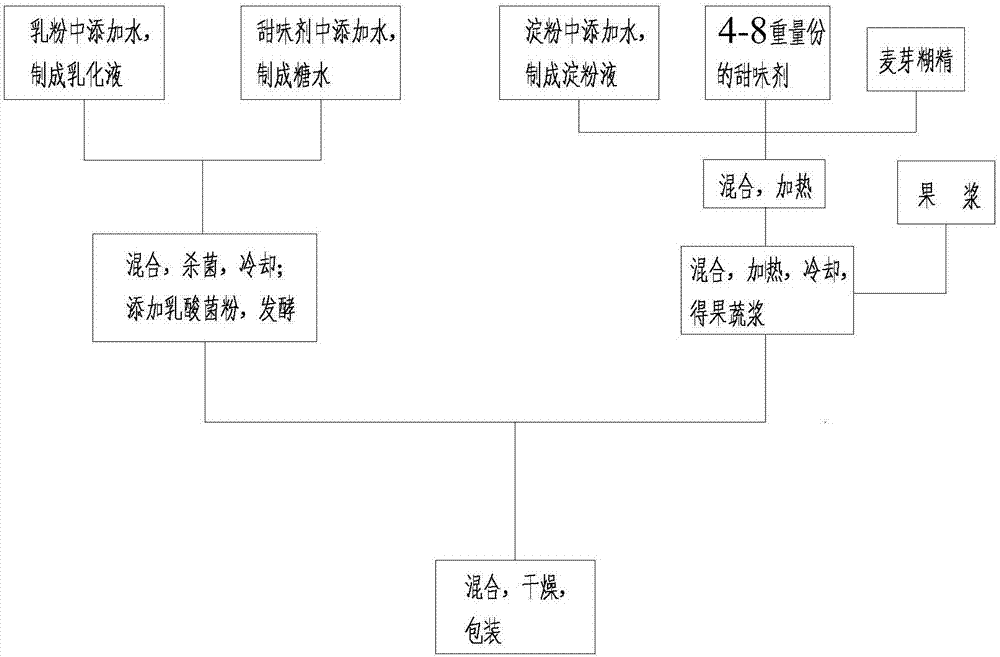

[0034] See attached figure 1 , a kind of preparation method of yogurt, comprises the following steps: 1) the preparation of starch liquid: add water in starch, mix uniformly, make the starch liquid that weight concentration is 5-15%; 2) the preparation of fruit and vegetable slurry: in step 1) Add maltodextrin and 6-8 parts by weight sweetener to the obtained starch liquid, stir evenly, heat at 80-90°C for 5-10min, then add fruit and vegetable pulp, and heat at 85-95°C , heated for 1-5min, cooled to 30-50°C to make fruit and vegetable slurry; 3) saccharification of sweetener: add water to the remaining sweetener, the weight of water is 2-3 times the weight of sweetener, Stir and saccharify at 45-60°C to make an aqueous sugar solution; 4) Preparation of emulsion: add water to the milk powder, the weight of the water is 4-7 times the weight of the milk powder, and stir at 40-50°C 5) Preparation of fermented liquid: add the aqueous sugar solution obtained in step 3) to the emuls...

Embodiment 1

[0041] Prepare yogurt as follows:

[0042] 1) Preparation of starch liquid: take 4 parts by weight of potato starch, add water to the starch, mix evenly, and make a starch liquid with a mass concentration of 10%;

[0043] 2) Preparation of fruit and vegetable slurry: In the starch liquid obtained in step 1), 4 parts by weight of maltodextrin and 4 parts by weight of xylitol are stirred evenly, heated at 80° C. for 10 minutes, and then 20 parts by weight of Mango pulp, heated at 85°C for 5 minutes, and cooled to 50°C to make mango pulp;

[0044] 3) Saccharification of aspartame: take 10 parts by weight of aspartame, add water to the mixture, the weight of water is 3 times of the weight of aspartame, stir and saccharify at 45°C to make aspartame sweet water solution;

[0045] 4) Preparation of emulsion: get 30 parts by weight of milk powder, the milk powder is a mixture of whole milk powder and skimmed milk powder, add water in the milk powder, the weight of water is 7 times o...

Embodiment 2

[0050] 1. Prepare apple pulp by following steps:

[0051] a) Soaking: Wash the apples, peel and core them, and soak them in the soaking solution for 50-70 minutes. The mass ratio of the soaking solution to the apples is 2:1-10:1. The soaking solution consists of vitamin C, citric acid, salt and water. Composition, the mass concentration of vitamin C in soaking liquid is 0.2%, the mass concentration of citric acid is 0.2%, the mass concentration of salt is 0.5%;

[0052] b) blanching, using the soaking solution obtained in step a) as a blanching solution, and blanching the apples obtained in step a) in the blanching solution. When blanching, the temperature of the blanching solution is 98°C, and the blanching time is 40s. The mass ratio of blanching liquid to apples is at least 20:1;

[0053] c) Cooling, cooling the apples obtained in step b) to below 20°C, and performing pulping to obtain apple pulp; the obtained apple pulp is also subjected to a probiotic fermentation step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com