Ceramic tile defect detection device adopting laser and camera composite detection mode and classification method

A composite detection and defect detection technology, which is applied in the direction of optical defect/defect detection, measuring devices, optical devices, etc., can solve the problems of failing to meet the manufacturer's inspection requirements and poor results, and achieve convenient and humanized operation and enhanced stability , Accurate process data collection and analysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

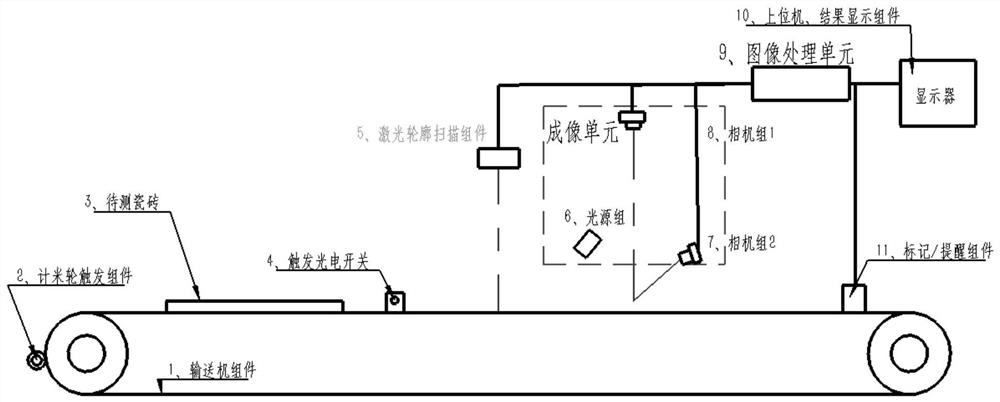

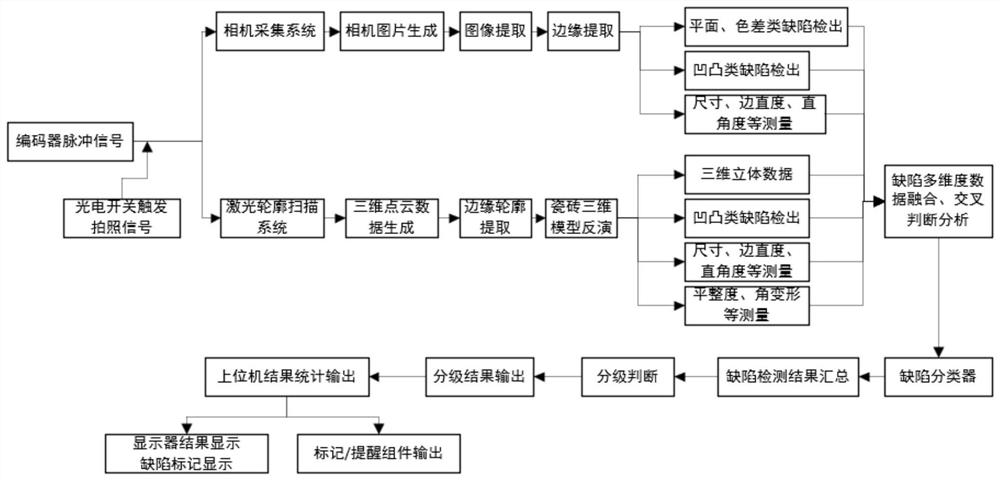

[0025] The tiles 3 are transported by the belt conveyor assembly 1. When the tiles 3 run to the photoelectric trigger assembly 4, the photoelectric trigger assembly 4 sends out a photoelectric trigger signal, which respectively triggers the laser profile scanning assembly 5 and the camera acquisition system 8 to start working. The camera acquisition system 8 includes at least one camera group, which may be two groups, the first camera group 7 and the second camera group 12, and also includes a light source group 6, wherein the light source group may be at least one group.

[0026] The first camera group 7 and the second camera group 12 start to shoot, and the camera acquisition system 8 and the laser profile scanning component 5 start to receive the pulse trigger signal of the meter wheel trigger component 2, and shoot the tile 3 to be tested, and pass the preset shooting The number of lines or the number of scanning pulses is limited to work until the end signal of the photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com