Calibration method for blackbody cavity absorption coefficient under variable temperature condition

A technology of absorption coefficient and black body cavity, which is applied in the field of calibration of black body cavity absorption coefficient under variable temperature conditions, can solve problems such as drift of black body cavity absorption coefficient and lack of real-time monitoring technology of black body cavity absorption rate, so as to reduce optical noise and improve testing Efficiency, the effect of improving signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

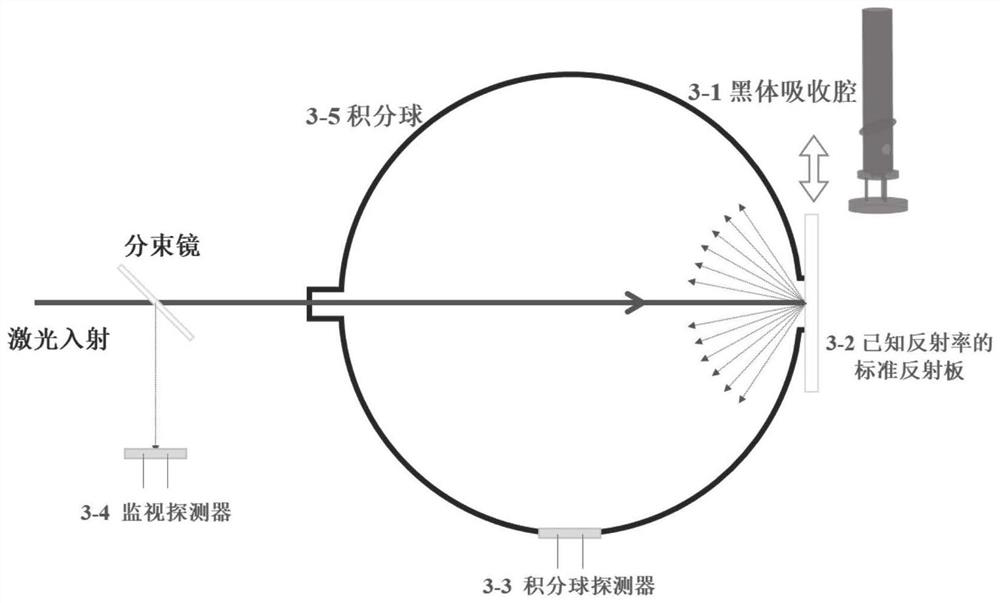

[0046] Aiming at the problem of temperature-varying real-time calibration of blackbody cavity absorptivity, the present invention greatly simplifies the optical path structure of the traditional integrating sphere method by introducing an upside-down photodetector. At the same time, it can realize the real-time monitoring of the absorption coefficient of the black body absorption cavity under the variable temperature environment.

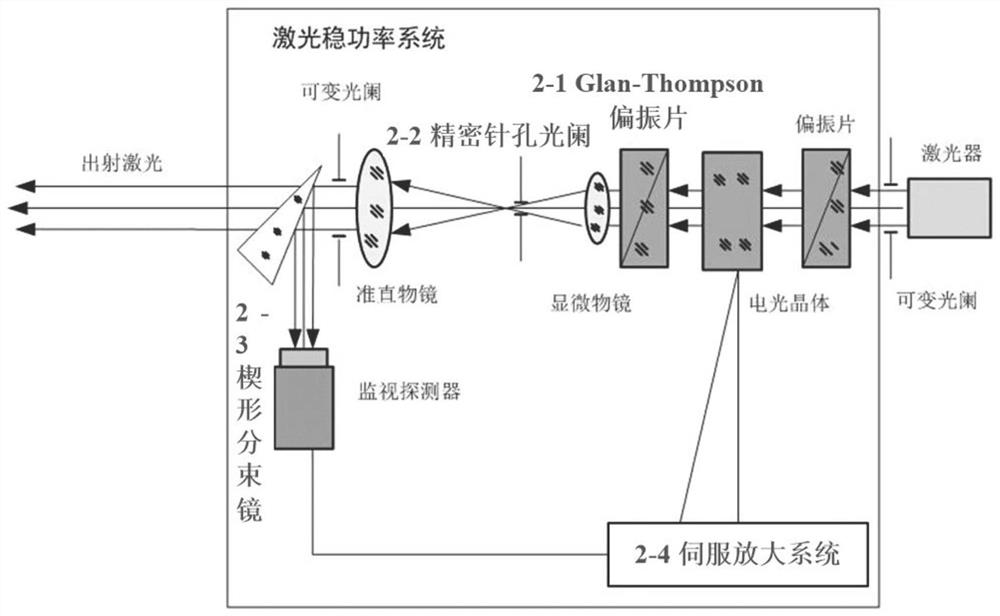

[0047] Such as figure 1 As shown, the calibration method of the variable temperature blackbody cavity absorption coefficient in this embodiment is realized based on the radiation source 1, the laser power stabilization system 2, the blackbody cavity absorption coefficient calibration system 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com