Low-temperature drying system without destroying effective components of collagen peptide powder

A technology of collagen peptide powder and active ingredients, which is used in dryers for static materials, drying solid materials without heating, drying solid materials, etc., can solve the problem of reducing the permeability of the observation window, inconvenient working conditions, lack of automatic observation window Cleaning and other issues to achieve the effect of improving permeability, reducing heat loss, and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

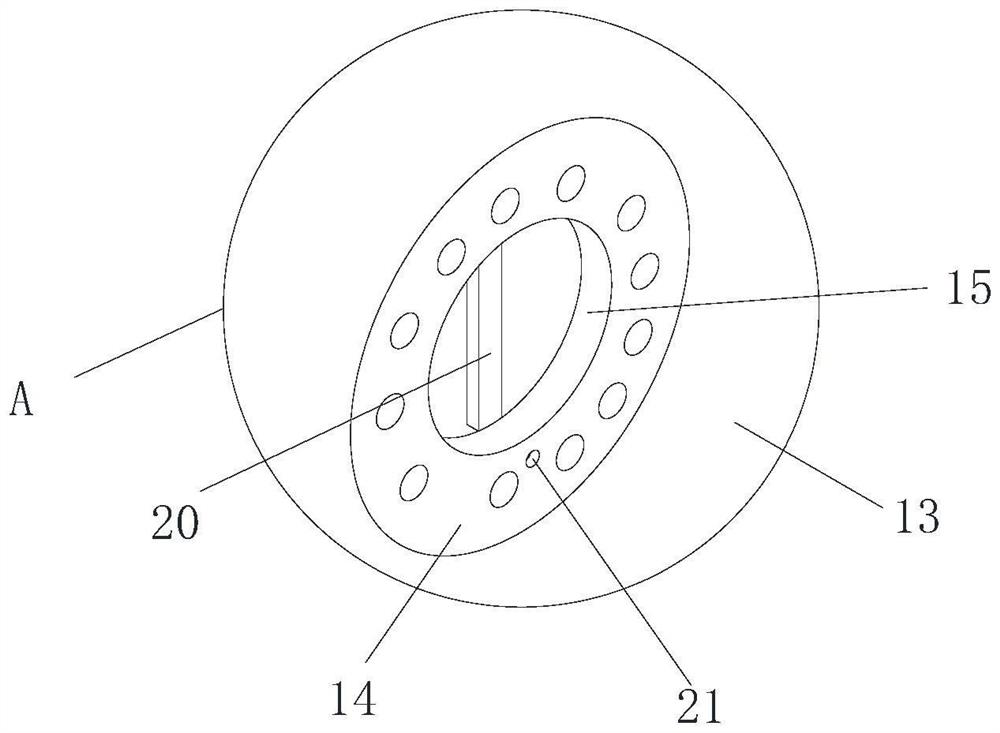

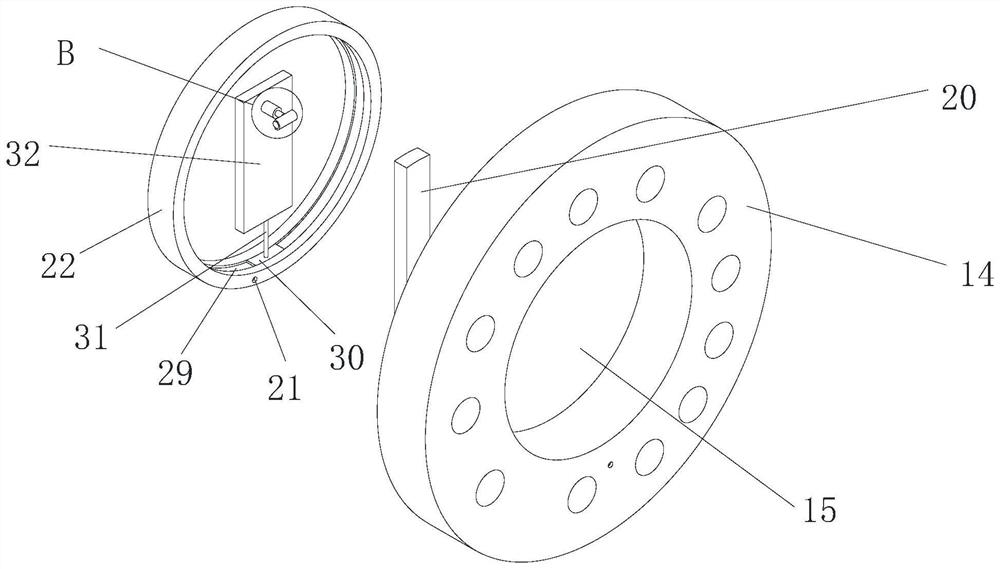

[0034] Embodiment: a kind of low-temperature drying system that does not destroy the active ingredient of collagen peptide powder, such as Figure 1-Figure 6As shown, it includes a drying tank 10, a supporting leg 11, a vacuum tank 12, a sealing cover 13, a flange 14, and an observation glass 15. The supporting leg 11 is fixedly connected with the drying tank 10, and the vacuum tank 12 is arranged on the drying tank 10. On the side, the vacuum tank 12 is connected to the drying tank 10 through a pipeline, the sealing cover 13 is connected to the drying tank 10 by bolts, the observation glass 15 is connected to the flange 14 and the flange 14 is installed on the end face of the sealing cover 13, and the observation glass 15 The surface is equipped with a cleaning mechanism, which includes a scraper 20, air hole 1 21, fixed ring 22, inner chute 23, partition plate 24, air hole 2 25, ejector rod 26, sliding block 27, strong magnetic block 28, and outer chute 29 And the metal bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com