Safety joint for grooved steel pipe

A technology of safety joints and pipe joints, which is applied in the field of pipeline connection of steel pipelines in the field, can solve the problems of increasing the frequency of maintenance and replacement, and achieve the effects of large bearing capacity, large bending angle and large transmission force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

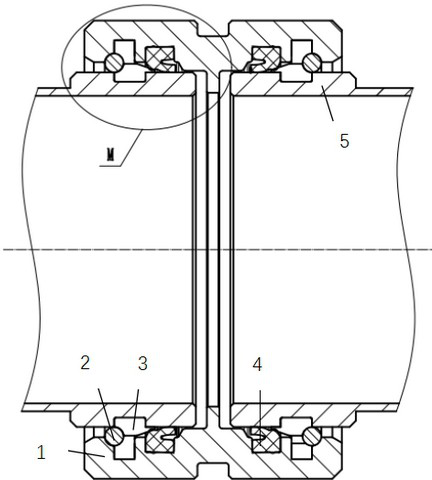

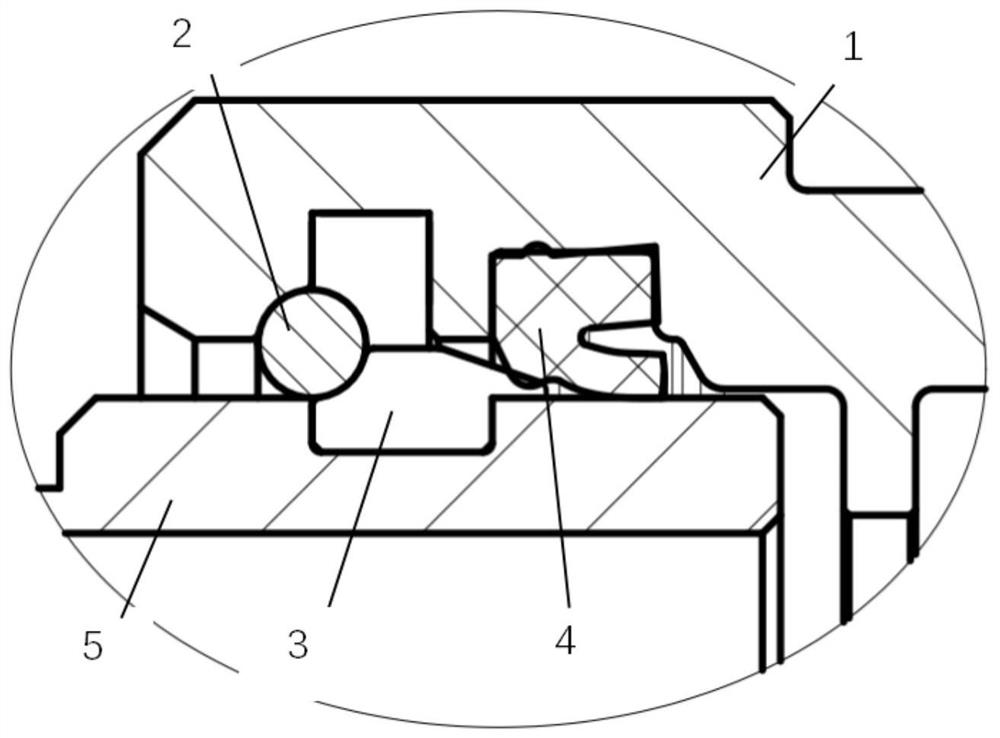

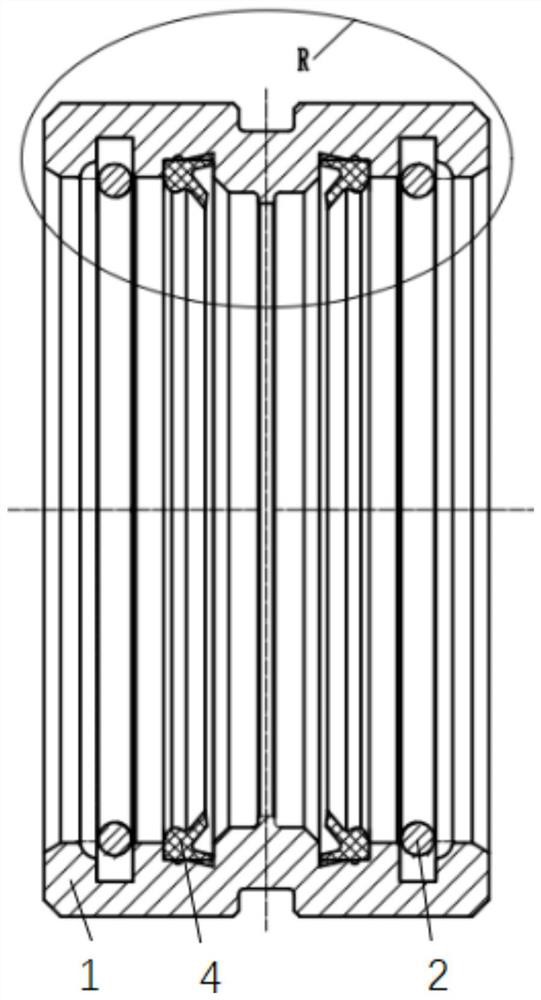

[0065] Figure 1-7 Among them, the safety joint for grooved steel pipe consists of a connector body 1, a grooved pipe joint snap ring 3, a steel locking ring 2, and a sealing rubber ring 4. Connector body 1. Grooved pipe joint snap ring should be made of 35Cr or thick-walled pipe with the same strength. Steel locking rings shall be manufactured using 65Mn cold drawn spring steel wire. The sealing rubber ring 4 should be made of nitrile oil-resistant rubber or synthetic oil-resistant rubber. The hardness of the outer surface of the connector body 1 is not lower than HRC28, and the surface hardness of the inner R3 arc is not lower than HRC32. The surface hardness of the grooved pipe joint snap ring 3 is not lower than HRC28, and the surface hardness of the steel locking ring 2 is not lower than HRC32. The steel locking ring 2 is in the shape of a circular ring with notches, and its inner diameter is slightly smaller than the outer diameter of the grooved pipe joint at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com