Bicycle derailleur

A technology of speed changer and speed change plate, which is applied in the direction of bicycle gear shifting mechanism, bicycle accessories, transportation and packaging, etc., can solve the problems of high failure rate, complex structure, poor reliability and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

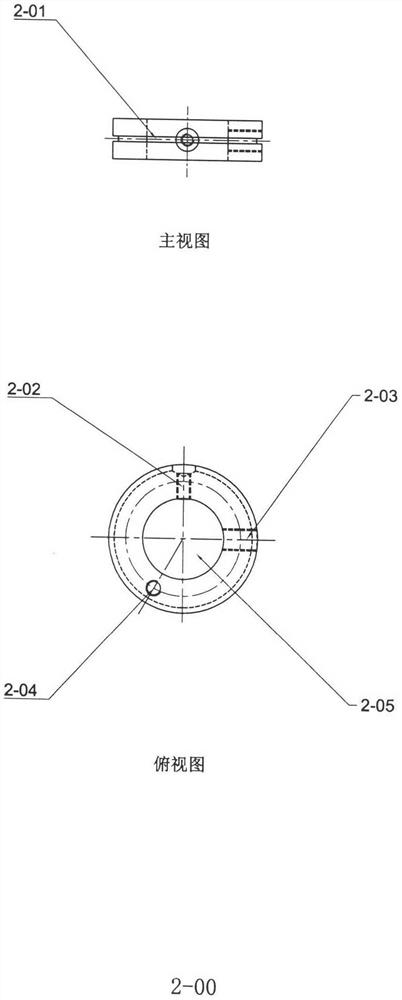

[0011] The transmission part is composed of: support plate (1), speed change plate (2-00), shaft sleeve (3), C-shaped fixing ring (4), positioning ball (7), handle (9), speed change line (10) ), the gear plate (2-00) is composed of: wire groove (2-01), wire fixing screw hole (2-02), handle hole (2-03), positioning bead hole (2- 04), the handlebar cover mounting hole (2-05) is composed of the C-shaped fixing ring (4-00) parts structure is: the support plate mounting hole (4-01), the handlebar cover mounting hole (2-02) , the positioning bead hole (2-03), the ring locking hole (4-04) is formed, the end of the C-shaped fixing ring (4-00) is drilled with 6 gear positioning socket holes or a few more, and The corresponding numbers 1-6 are engraved, and a locking screw (5) is also installed, which can be locked on any position of the shaft sleeve (3), and a support plate (1) with a threading hole (6) on it. ), fix the shifting cable (10) on the shifting disc (2-00) through the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com