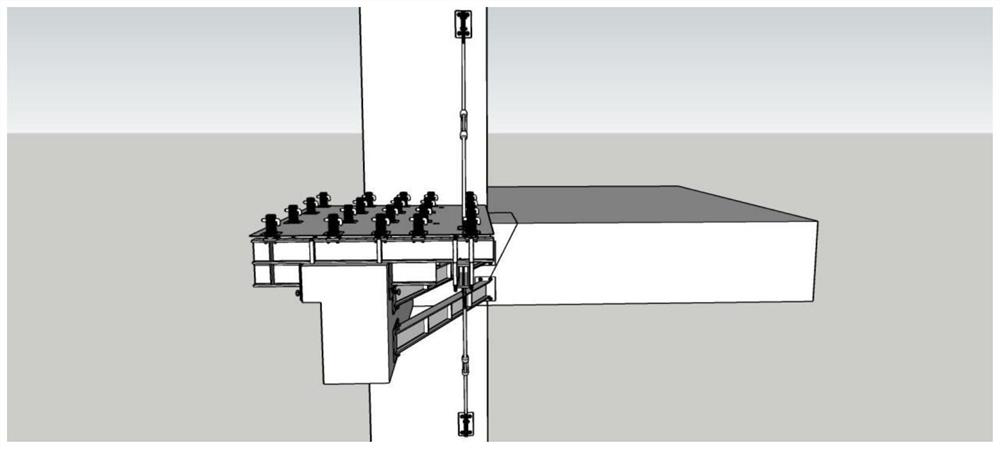

Platform vertical rod base

A pole and platform technology, applied in the field of semi-suspended platform support frame erection, can solve the problems of difficulty in construction, high erection cost and high safety risk, achieve high reusability, improve integrity and overall rigidity, and simple and convenient clamping method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

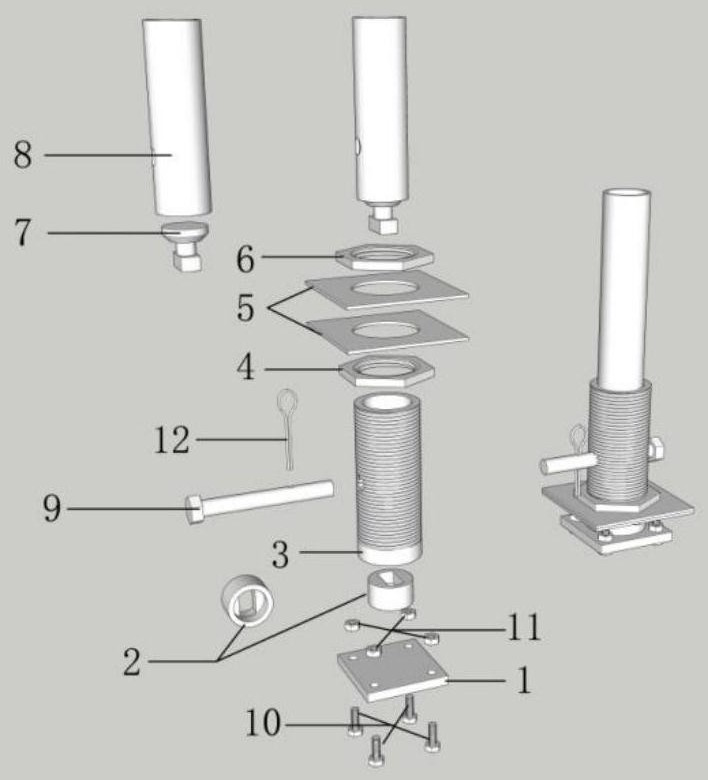

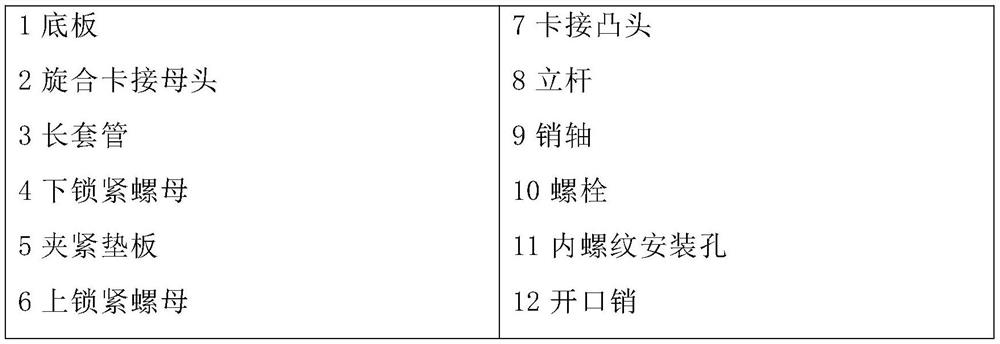

[0033] Embodiment 1: The bottom plate 1 is provided with four internal threaded holes; the bottom plate 1 is welded with a screw-in clamp female head 2, and the outer diameter of the screw-in clamp female head 2 is equal to the outer diameter of the steel pipe to be connected. The female head 2 is divided into two parts from the middle in the thickness direction, and the upper part is the insertion port of the screwed and clipped protrusion 7 welded at the bottom of the vertical rod 8. The length of the connection line of the points, that is, the diameter is smaller than the diameter of the screw-in clamping female head 2, so as to ensure that there is enough stress area around the upper part of the insertion port to ensure its bearing capacity; the lower part is a circular inner hollow clamping cavity, and the clamping Sufficient wall thickness is left around the joint cavity to ensure sufficient bearing capacity, and at the same time ensure that the inserted clamping protrusi...

Embodiment 2

[0038] Embodiment 2: The difference from Embodiment 1 is that the pole base of this platform also includes a cotter pin 12, which is inserted into a through hole in the diameter direction provided at the tail end of the pin shaft 9 to prevent the pin shaft 9 from falling off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com