Litchi puree wine and preparation method thereof

A technology for puree wine and lychee, which is applied in the field of winemaking, can solve the problems of lychee pit abandonment, intractability, and lychee pit waste, and achieve the effects of expanding the variety of raw materials, fresh fruit aroma and pure taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

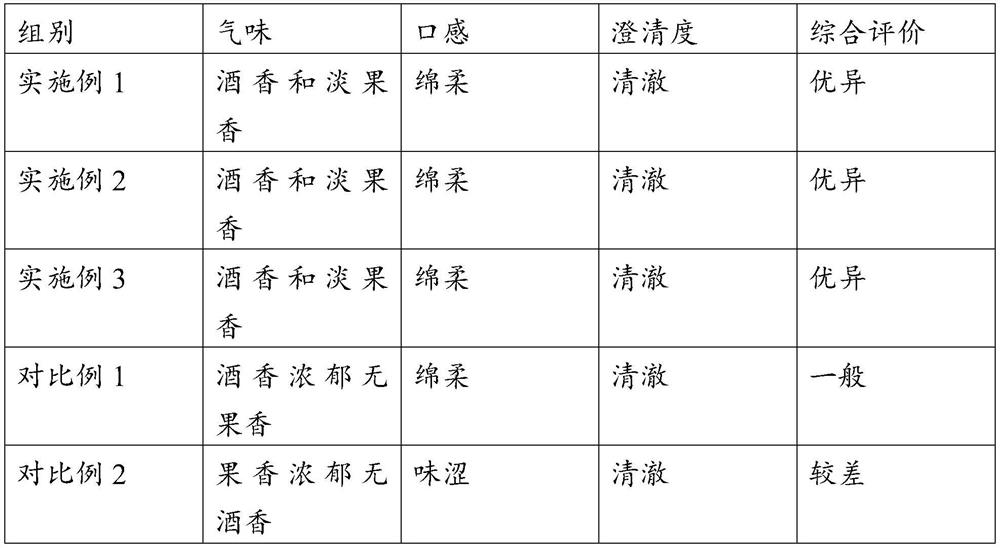

Examples

preparation example Construction

[0028] The present invention also provides the preparation method of described lychee puree wine, comprises the steps:

[0029] (1) crushing the lychee core, mixing with rice and sorghum, steaming and cooling to 25-35°C to obtain material 1;

[0030] (2) Insert distiller's yeast into material 1, and saccharify for 15-30 hours to obtain material 2;

[0031] (3) adding enzyme after beating litchi pulp, and obtaining material 3 after enzymatic hydrolysis;

[0032] (4) After mixing material 2 and material 3, add water and ferment for 5-15 days;

[0033] (5) Filter and age after fermentation to obtain lychee puree wine.

[0034] In the present invention, in the step (1), the size of the crushed litchi core is preferably 1-4 mm, more preferably 2-3 mm.

[0035] In the present invention, the temperature after cooling in the step (1) is preferably 28-32°C, more preferably 30°C.

[0036] In the present invention, the amount of distiller's yeast in the step (2) is preferably 1.2 to ...

Embodiment 1

[0048] (1) Weigh 50 kg of lychee core and crush it to 4 mm, mix the crushed lychee core with 550 kg of rice and 160 kg of sorghum, steam and cool to 25° C. to obtain material 1;

[0049] (2) Insert 9.12kg of distiller's yeast into material 1, and saccharify at 26°C for 30 hours to obtain material 2;

[0050] (3) Add 90 g of pectinase after beating 300 kg of lychee pulp, and obtain material 3 after enzymatic hydrolysis;

[0051] (4) Add 212kg of water after mixing material 2 and material 3, and ferment for 15 days at 24°C;

[0052] (5) After the fermentation is finished, filter and age at 18°C for 70 days to obtain lychee puree wine.

Embodiment 2

[0054] (1) Weigh 90 kg of lychee cores and crush them to 1 mm, mix the crushed lychee cores with 450 kg of rice and 120 kg of sorghum, steam and cool to 35° C. to obtain material 1;

[0055] (2) Insert 10.56kg of distiller's yeast into material 1, and saccharify at 29°C for 15 hours to obtain material 2;

[0056] (3) Add 160 g of pectinase after beating 400 kg of lychee pulp, and obtain material 3 after enzymatic hydrolysis;

[0057] (4) Add 159kg of water after mixing material 2 and material 3, and ferment for 15 days at 28°C;

[0058] (5) After the fermentation is finished, filter and age at 24° C. for 50 days to obtain lychee puree wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com