Rapidly calcined lightweight plastering gypsum and preparation method thereof

A plastering gypsum and calcining technology, which is applied in the field of rapid calcination of light plastering gypsum and its preparation, can solve the problems of low strength, cracking and the like, and achieves the improvement of coating rate, overcoming easy cracking, high coating rate and construction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

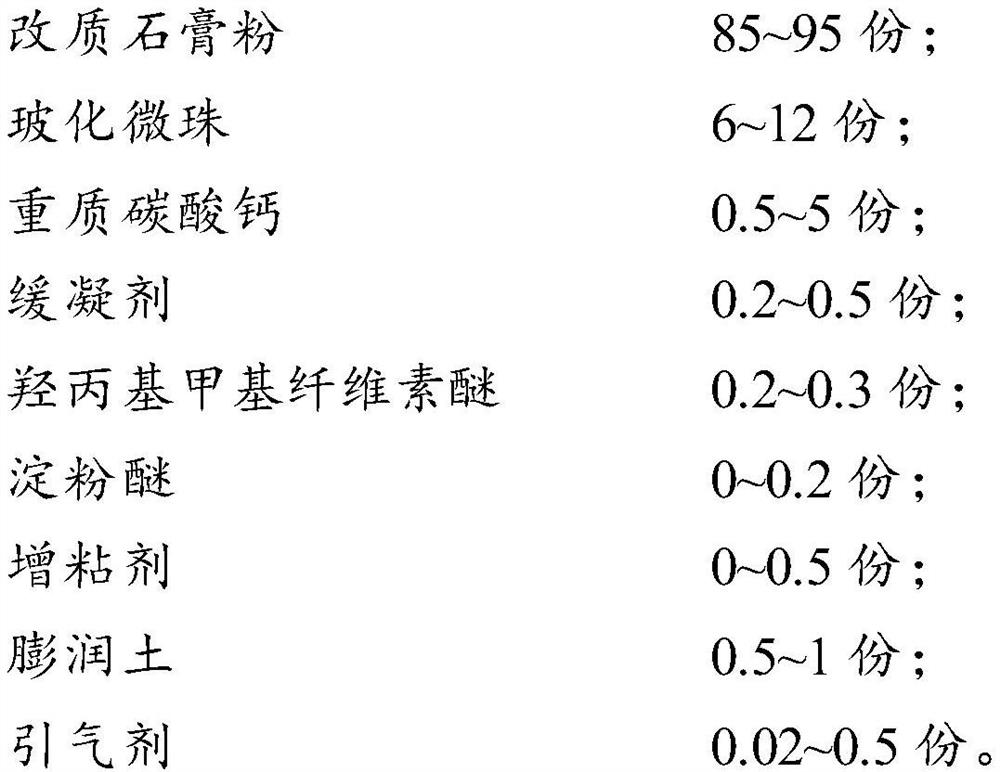

[0041] The present invention also provides a method for preparing the fast-calcined lightweight plastering gypsum described in the above technical solution, comprising:

[0042] Mix modified gypsum powder, vitrified microbeads, heavy calcium carbonate, retarder, hydroxypropyl methylcellulose ether, starch ether, tackifier, bentonite and air-entraining agent to obtain fast calcined lightweight plaster plaster.

[0043] In the present invention, the order of mixing materials is preferably: first stir and mix the modified gypsum powder and retarder, then add heavy calcium carbonate, air-entraining agent, bentonite, tackifier, starch ether and hydroxypropyl methyl The cellulose ether is stirred and mixed, and finally vitrified microbeads are added and stirred and mixed to obtain a fast calcined light plastering gypsum.

[0044] In the present invention, the above-mentioned mixing step is preferably carried out in a mixer, and the stirring rate during the mixing process is prefera...

Embodiment 1

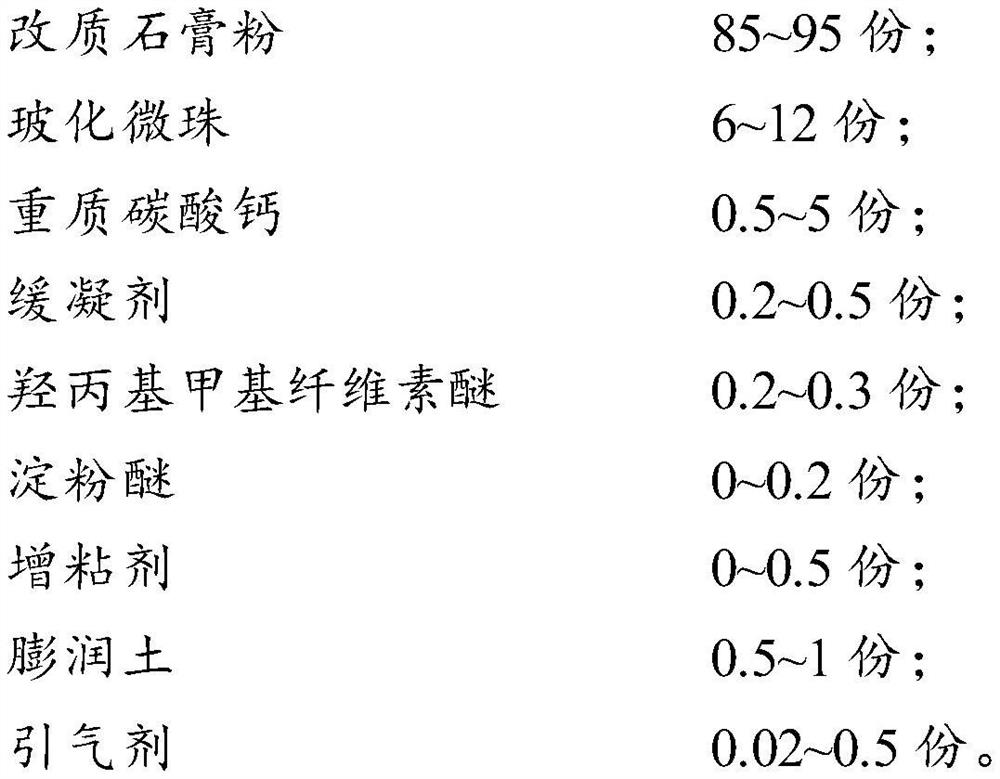

[0047] 1.1 Raw material

[0048]

[0049]

[0050] in:

[0051] Modified gypsum powder specifications: temperature 48°C, fineness 60-120 mesh, loose bulk density 670g / L; three-phase composition: residual dihydrate gypsum content 2.48%, anhydrous gypsum content 2.83%, hemihydrate gypsum content 76.42% . Obtained in the following manner: high-temperature rapid calcined gypsum powder (temperature 590-600° C.) is obtained through cyclic cooling, homogenization and aging treatment.

[0052] Vitrified microbeads are: spherical closed-cell expanded perlite, loose bulk density 119g / L, fineness 30-90 mesh, fineness modulus 2.2, water sinking rate 4%, cylinder compressive strength 160kPa.

[0053] Heavy calcium carbonate: fineness 325 mesh, loose bulk density 950g / L.

[0054] Hydroxypropyl methyl cellulose ether: viscosity is 60000mPa.s.

[0055] Retarder: Suzhou Xingbang SG-12 efficient retarder.

[0056] 1.2 Preparation:

[0057] Weigh the retarder SG-12 by micrometering, ...

Embodiment 2

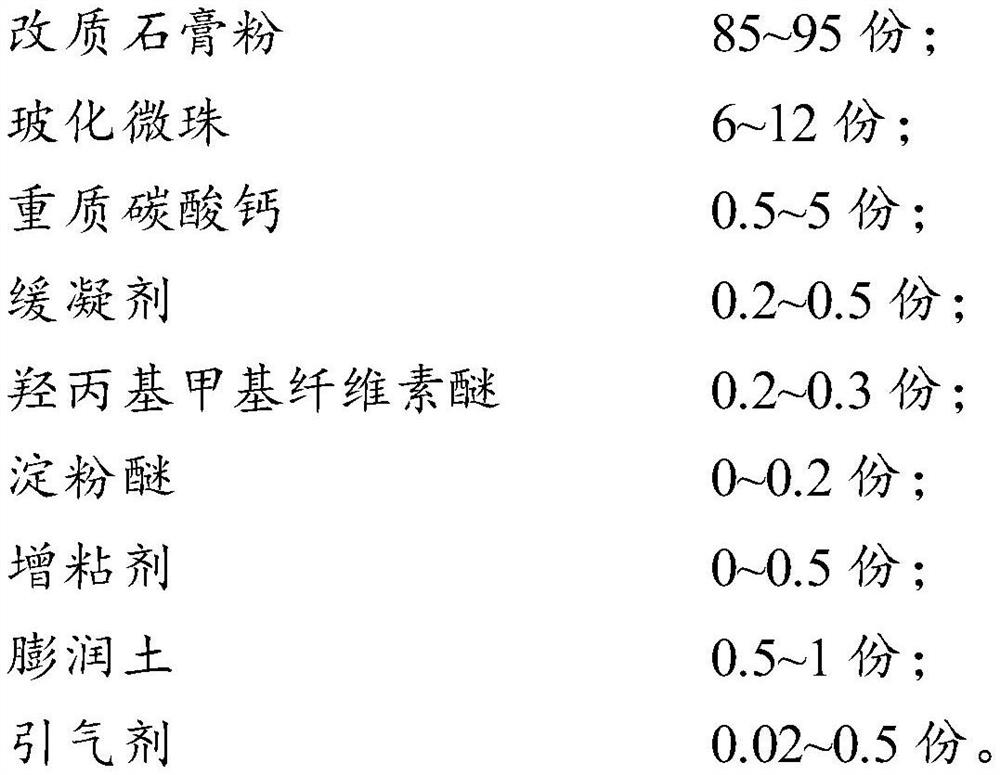

[0059] 1.1 Raw material

[0060]

[0061] in:

[0062] Modified gypsum powder specifications: temperature 49°C, fineness 50-120 mesh, loose bulk density 670g / L; three-phase composition: residual dihydrate gypsum content 2.92%, anhydrous gypsum content 2.95%, hemihydrate gypsum content 79.31% . Obtained in the following manner: high-temperature rapid calcined gypsum powder (temperature 630-650° C.) is obtained through cyclic cooling, homogenization and aging treatment.

[0063] Vitrified microbeads are: spherical closed-cell expanded perlite, loose bulk density 119g / L, fineness 30-90 mesh, fineness modulus 2.2, water sinking rate 4%, cylinder compressive strength 160kPa.

[0064] Heavy calcium carbonate: fineness 325 mesh, loose bulk density 950g / L.

[0065] Hydroxypropyl methyl cellulose ether: viscosity is 60000mPa.s.

[0066] Retarder: Suzhou Xingbang SG-12 efficient retarder.

[0067] 1.2 Preparation:

[0068] Weigh the retarder SG-12 by micrometering, and add it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com