Elastic texture paint and preparation method thereof

A texture coating and elastic technology, applied in the field of elastic texture coating and its preparation, can solve the problems of large pores, easy to absorb dust, and insufficient compactness of the coating film, and achieve high coating rate, good leveling, and excellent crack resistance Effects on sex and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

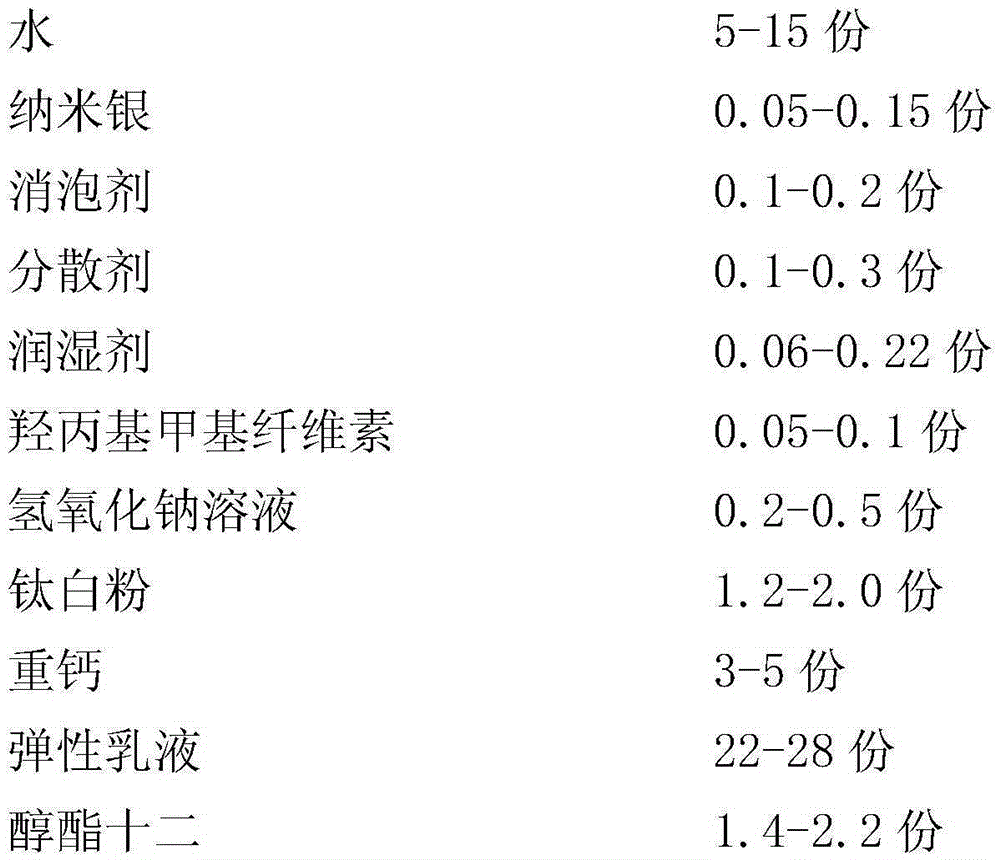

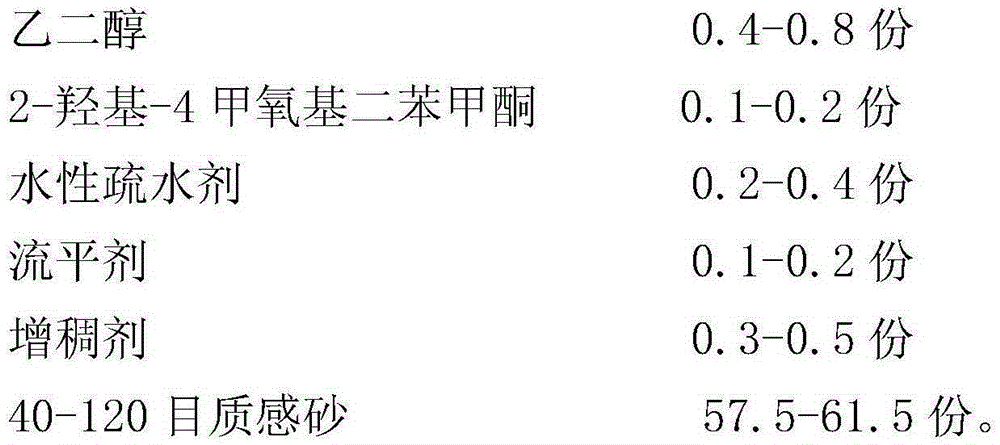

[0025] A kind of elastic texture coating is prepared by the following components and weight ratio:

[0026]

[0027]

[0028] A kind of preparation method of elastic texture paint, it comprises the steps that are carried out in sequence as follows:

[0029] (1) Preparation of base paint: Add 10 parts of water, 0.1 part of nano-silver, 0.15 part of defoamer, 0.2 part of dispersant and 0.14 part of wetting agent into the dispersion tank, mix it into a premix, and add it at a speed of 300r / min 0.06 parts of hydroxypropyl methylcellulose and 0.4 parts of sodium hydroxide solution, stirred for 4 minutes. Then, increase the rotation speed to 800r / min, add 1.6 parts of titanium dioxide, stir for 8 minutes, then reduce the rotation speed to 500r / min, add 25 parts of elastic emulsion, and stir for 1-2 minutes. Then add 1.8 parts of alcohol ester dodecane, 0.6 parts of ethylene glycol, 0.15 parts of 2-hydroxy-4 methoxybenzophenone, 0.3 parts of water-based hydrophobic agent and 0...

specific Embodiment example 2

[0032] A kind of elastic texture coating is prepared by the following components and weight ratio:

[0033]

[0034]

[0035] A kind of preparation method of elastic texture paint, it comprises the steps that are carried out in sequence as follows:

[0036] (1) Preparation of base paint: Add 5 parts of water, 0.05 parts of nano-silver, 0.1 part of defoamer, 0.1 part of dispersant and 0.22 parts of wetting agent into the dispersion tank, mix it into a premix, and add it at a speed of 600r / min 0.04 parts of hydroxypropyl methylcellulose and 0.3 parts of sodium hydroxide solution, stirred for 6 minutes. Then, increase the rotation speed to 1500r / min, add 1.2 parts of titanium dioxide, stir for 12 minutes, then reduce the rotation speed to 800r / min, add 28 parts of elastic emulsion, and stir for 2 minutes. Then add 2.2 parts of alcohol ester dodecane, 0.8 parts of ethylene glycol, 0.2 parts of 2-hydroxy-4 methoxybenzophenone, 0.2 parts of water-based hydrophobic agent and 0...

specific Embodiment example 3

[0039] A kind of elastic texture coating is prepared by the following components and weight ratio:

[0040]

[0041]

[0042] A kind of preparation method of elastic texture paint, it comprises the steps that are carried out in sequence as follows:

[0043] (1) Preparation of base paint: Add 15 parts of water, 0.15 parts of nano-silver, 0.2 parts of defoamer, 0.3 parts of dispersant and 0.06 parts of wetting agent into the dispersion tank, mix them into a premix, and add them at a speed of 400r / min 0.08 parts of hydroxypropyl methylcellulose and 0.5 parts of APM-95, stirred for 5 minutes. Then, increase the rotation speed to 1200r / min, add 2.0 parts of titanium dioxide, stir for 10 minutes, then reduce the rotation speed to 700r / min, add 22 parts of elastic emulsion, and stir for 2 minutes. Then add 1. part of alcohol ester dodecane, 0.4 part of ethylene glycol, 0.1 part of 2-hydroxy-4 methoxybenzophenone, 0.4 part of water-based hydrophobic agent and 0.2 part of leveli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com