Processing and storing device for chemical fiber sewing threads

A chemical fiber and storage device technology, applied in the field of sewing thread storage device, chemical fiber sewing thread processing storage device, can solve the problems of laborious transfer, energy waste, etc., to improve efficiency, reduce energy waste, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

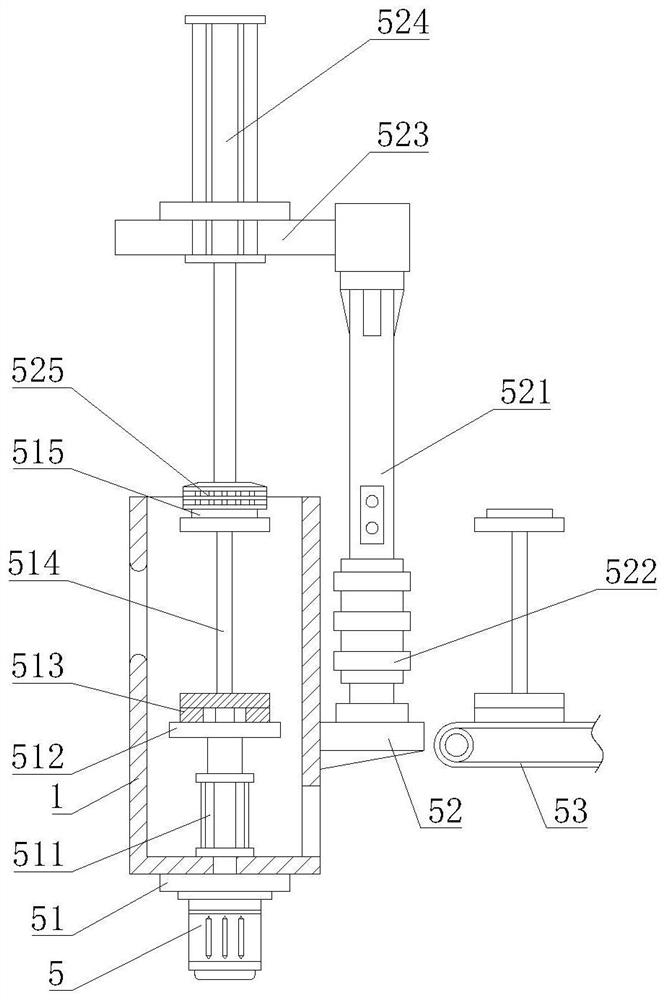

[0036] Such as Figure 1-8 As shown, the present invention provides a processing and storage device for chemical fiber sewing thread, including a storage box 1, the bottom of the storage box 1 is fixedly welded with support legs 2, and the front of the storage box 1 is fixedly installed with a transparent plate 3, The right side of the storage box 1 is detachably connected with a cleaning door 4, the right side of the storage box 1 is provided with a labor-saving transfer mechanism 5, the left side of the storage box 1 is provided with an idling monitoring mechanism 6, and the left side of the storage box 1 A comprehensive drying mechanism 7 positioned on the left side of the idling monitoring mechanism 6 is provided. The labor-saving transfer mechanism 5 includes a storage motor 51, a side support frame 52 and a moving conveyor belt 53. The moving conveyor belt 53 is arranged on the right side of the storage box body 1, and the side The bracket 52 is fixedly welded on the rig...

Embodiment 2

[0038] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the storage motor 51 is fixedly installed at the bottom of the storage box 1, and the output shaft of the storage motor 51 extends to the inner cavity of the storage box 1 The middle is fixedly connected with a storage electric telescopic rod 511, and the mobile end of the storage electric telescopic rod 511 is fixedly installed with a fixed seat 512, and the top of the fixed seat 512 is fixedly installed with a cross clamp block, and the top of the cross clamp block is movably connected with a connection seat 513. The top of seat 513 is fixedly installed with receiving roller 514, and the top of receiving roller 514 is fixedly installed with irony plate 515, and the top of irony plate 515 is movably connected with the bottom of transfer electromagnet 525, manually rotates manual rotating rod 521, makes transfer electromagnet The iron 525 moves to...

Embodiment 3

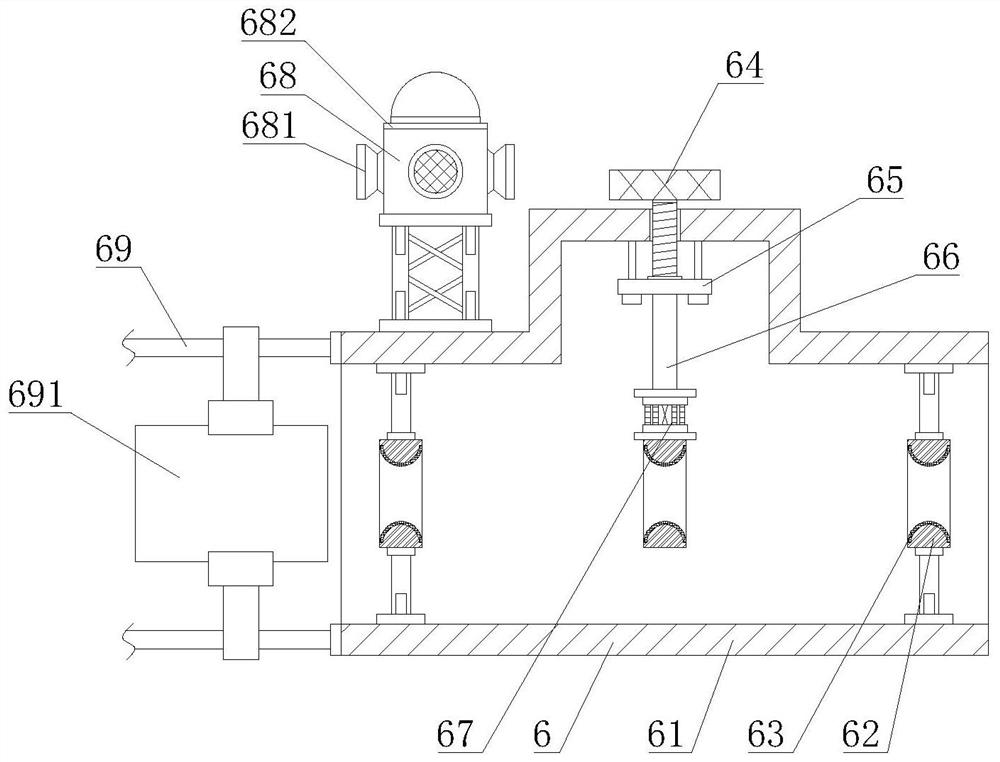

[0040] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, an elevated alarm box 68 is fixedly installed on the top of the monitoring cylinder 61, and a buzzer is arranged in the cavity of the elevated alarm box 68 , the outer wall of the raised alarm box 68 is fixedly connected with a loudspeaker tube 681, the top of the raised alarm box 68 is fixedly installed with a fixed top plate 682, and the bottom of the fixed top plate 682 is fixedly installed with a drive motor 683, and the output shaft of the drive motor 683 extends A rotating top base 684 is fixedly connected to the top of the fixed top plate 682, and the rotating top base 684 is rotatably connected to the top of the fixed top plate 682. The top of the rotating top base 684 is movably clamped with a transparent protective cover 685, and the center of the top of the rotating top base 684 A strobe light 686 is fixedly installed, a damping rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com