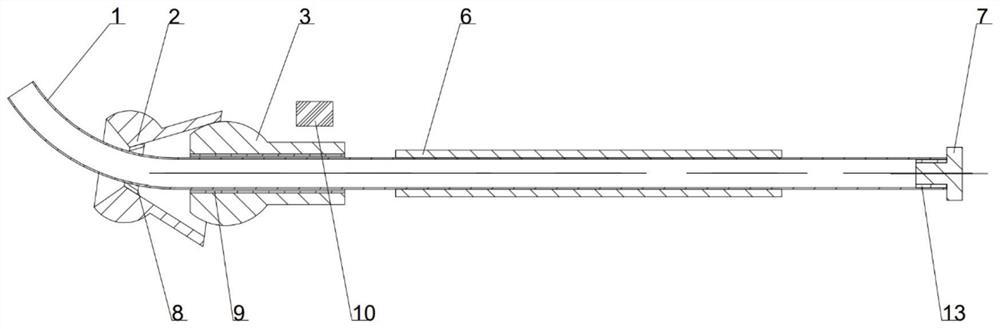

Three-dimensional free forming device and method based on current auxiliary heating

A technology of auxiliary heating and electric current, applied in the field of three-dimensional free forming device based on electric current auxiliary heating, can solve the problems of surface wrinkling and cross-section distortion, and achieve the effect of increasing plasticity, reducing forming difficulty and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Before the bending of 304 stainless steel pipes, the thermal-electrical coupling model in ABAQUS software is used to simulate the distribution of temperature and electric field during bending, and the mapping relationship between current parameters and pipe materials is established; at the same time, the eccentricity is 1mm, The temperature and potential changes at 2mm, 3mm, 4mm, 5mm... are simulated, and the mapping relationship between current parameters and pipe eccentricity is established.

[0026] The process analysis is carried out for 304 stainless steel pipes, and the eccentricity U=10mm when the bending radius R=75mm is obtained. According to the simulation results before bending, the current parameters required for the heating and forming of 304 stainless steel pipes are obtained;

[0027] Import the process parameters into the three-dimensional free bending forming system, and set the preset value of the infrared sensor to 630°C;

[0028] Power on the curren...

Embodiment 2

[0032] Before the bending of TC4 titanium alloy pipe, the thermal-electric coupling model in ABAQUS software is used to simulate the distribution of temperature and electric field during bending, and the mapping relationship between current parameters and pipe materials is established; at the same time, the eccentricity is 1mm , 2mm, 3mm, 4mm, 5mm... to simulate the temperature and potential changes, and establish the mapping relationship between the current parameters and the eccentricity of the pipe.

[0033] The process analysis is carried out for the TC4 titanium alloy pipe, and the eccentricity U=12mm when the bending radius R=75mm is obtained. According to the simulation results before bending, the current parameters required for TC4 titanium alloy pipe heating and forming are obtained;

[0034] Import the process parameters into the three-dimensional free bending forming system, and set the sensor preset value to 700°C;

[0035] Apply current to the current-assisted he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com