A path planning method for pressure vessel hemisphere additive manufacturing

A technology of path planning and additive manufacturing, applied in the field of additive manufacturing, to achieve the effect of reducing forming difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

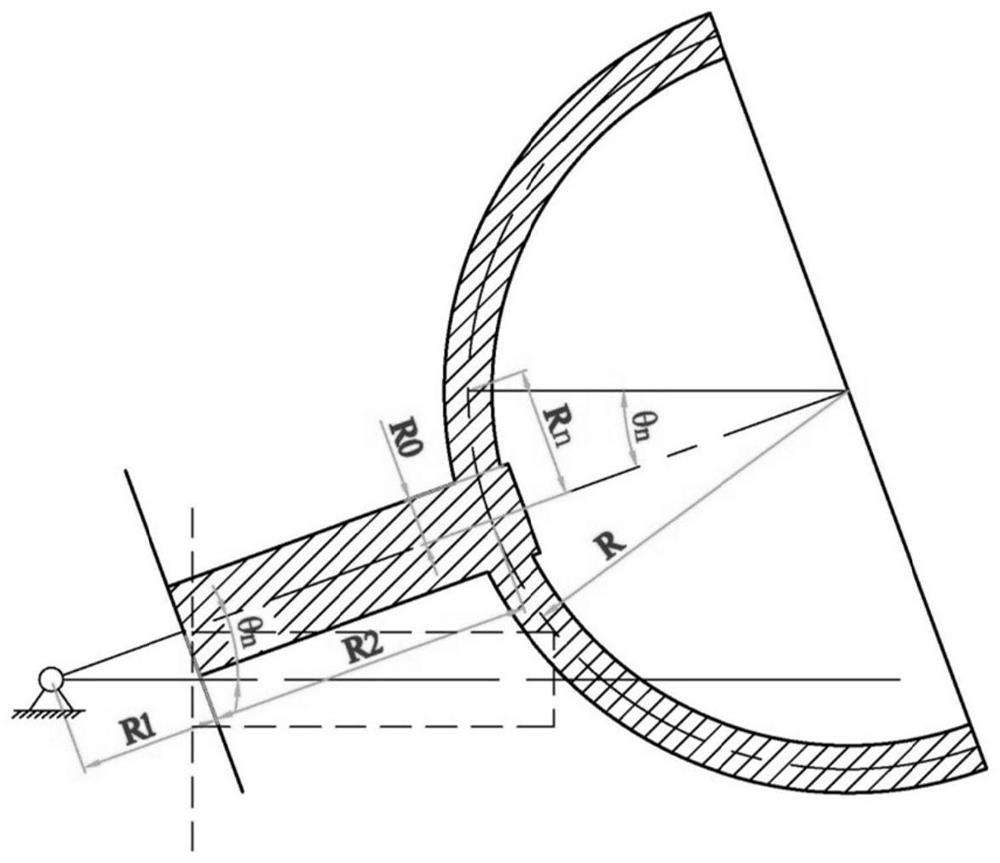

[0037] The purpose of the present invention is to propose a path planning method for fused wire additive manufacturing technology, solve the manufacturing problems of large-size hemispherical pressure vessel components, and improve the forming quality and production efficiency of additive manufacturing.

[0038] Fused wire additive manufacturing technology uses arc or electron beam as heat source to melt metal wire, and deposits fully dense, high-performance large metal components layer by layer. For the hemispherical container, the cross-sectional shape of each layer is inconsistent, and the inclination angle changes gradually, and its deposition path requires coordinated movement of multi-axis actuators.

[0039] The present invention proposes following two schemes:

[0040] Option 1: Use a fixed heat source to realize the deposition path only through a two-axis positioner. The center of the hemisphere coincides with the center of the turning axis of the positioner. Every t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com