Thick-bottom glass injection bottle with conical groove and manufacturing method of thick-bottom glass injection bottle

A technology of injection bottles and tapered grooves, which is applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of toxic and harmful drug leakage, troublesome glass bottle handling, and waste of liquid medicine, etc., to solve the problem of injection The problem of scrapping, the liquid is absorbed without residue, and the effect of scratching the skin is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

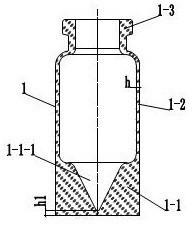

[0031] Referring to Fig. 1, the glass injection bottle with a thick bottom and tapered groove according to the present invention uses a glass tube with a wall thickness of 1.5-3 mm as a raw material and is formed by a firing process; the glass injection bottle 1 includes a bottle mouth 1-3, the bottle body 1-2 and the bottle bottom 1-1; the bottle bottom 1-1 is a thickened structure, and the center of the inner wall of the bottle bottom 1-1 is an inverted tapered groove 1-1- 1; The upper end of the tapered groove 1-1-1 communicates with the inner cavity of the bottle

[0032] The internal stress of the glass injection bottle is eliminated by heat treatment. , the wall thickness h1 at the lowest point of the tapered groove 1-1-1 is not less than 1.5mm, that is, h1≥1.5mm.

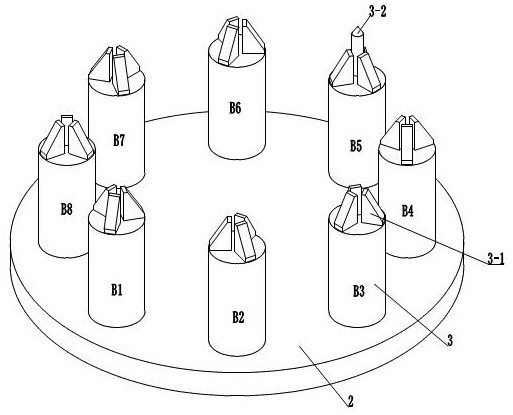

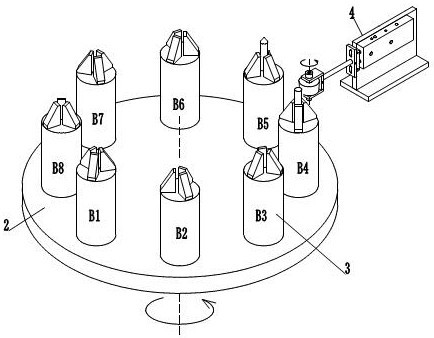

[0033] see figure 1 , figure 2 , the method for making a glass injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com