Drainage and overflow integrated drainer

An integrated, overflowing technology, used in water supply installations, buildings, indoor sanitary piping installations, etc., can solve problems such as increased manufacturing costs, water leakage, and cumbersome installation, and achieve safe overflow protection, large circulation area, and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

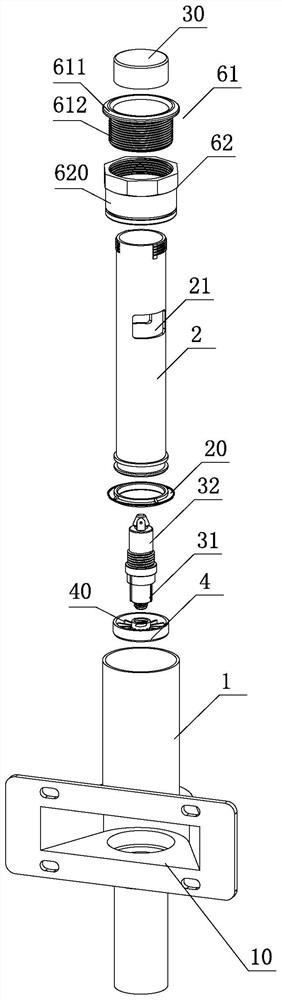

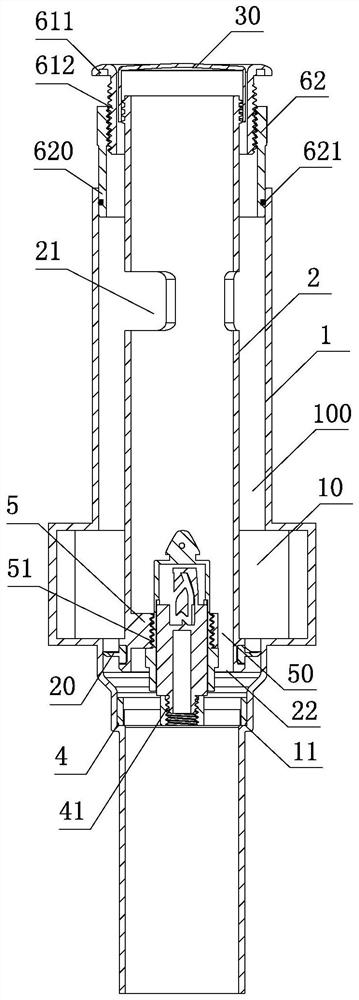

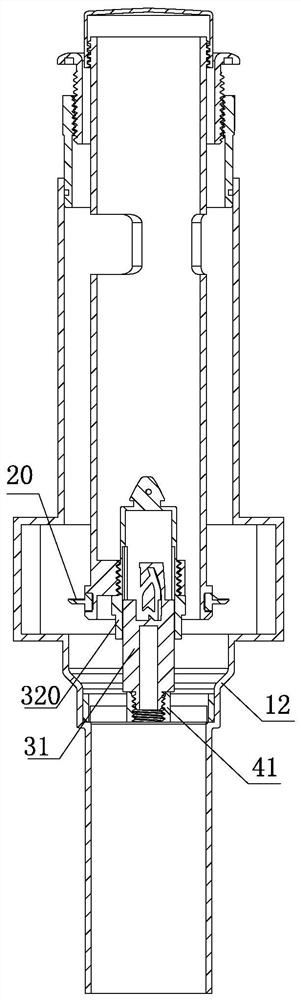

[0025] Embodiment 1, with reference to figure 1 , 3 .

[0026] The drainage and overflow integrated drain device provided by the present invention includes a switch and a drain tube 1. The drain tube is a straight tubular cylinder with a drain and overflow port 10 on the wall; the normal drainage and overflow of the sanitary ware pass through this port.

[0027] A liftable rigid connecting pipe 2 is provided in the water tank 1, and the rigid connecting pipe 2 is connected with the switch so as to be operated to descend and rise. There is a gap 100 between the rigid connecting pipe 2 and the water tank 1, The rigid connecting pipe 2 and the water tank 1 are generally arranged concentrically, and the outer diameter of the rigid connecting pipe 2 is smaller than that of the water tank 1, so the gap 100 is an annular gap with a certain height.

[0028] The lower part of the rigid connecting pipe 2 is provided with a sealing member 20, which is used as the opening and closing pa...

Embodiment 2

[0034] Embodiment 2, with reference to Figure 4 , and combined with the reference Figure 1-3 .

[0035] The structure of the present invention is not only suitable for the switch to be installed on the lower end of the rigid connecting pipe 2, but also suitable for the switch to be installed on the upper end of the rigid connecting pipe 2. In this embodiment, the switch is installed on the upper end of the rigid connecting pipe 2 as an example:

[0036] Described switch comprises fixed part 31b and lift part 32b, and the cooperation relation of fixed part 31b and lift part 32b is the same as embodiment 1, only fixed part 31b is provided with axial through hole, and the integral body of lift part 32b is from the axis of fixed part 31b. Pass through the through hole, and connect with the upper end of the lifting rigid connecting pipe 2 at the lower end. The upper end of the lifting portion 32b is connected to the button 30b.

[0037] When the lifting rigid connecting pipe ...

Embodiment 3

[0044] Embodiment 3, with reference to Figure 5-7 , and combined with the reference Figure 1-3 .

[0045] This embodiment is basically the same as Embodiment 1. Only in the installation method of the drainer, the nut and its lower connecting cylinder are all used as the appearance part 62c, and the upper part of the component 62c is threaded with the central connecting cylinder 611 using internal threads, and the drain cylinder 1 is inserted into the inside of the component 62c, and The socket in the non-embodiment 1 is outside the connecting cylinder 620 . From an installation point of view, this is easier to install and the appearance of the part is easier to handle.

[0046] The other parts of this embodiment are the same as Embodiment 1, and the corresponding parts and structures adopt the same Figure 1-3 The same reference numerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com