Automatic arranging and sorting machine for diamond-shaped products

An automatic sorting and sorting machine technology, applied in sorting and other directions, can solve problems such as unguaranteed test results, inability to arrange, omission or sorting errors, etc., to ensure test results, prevent omissions or sorting errors, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

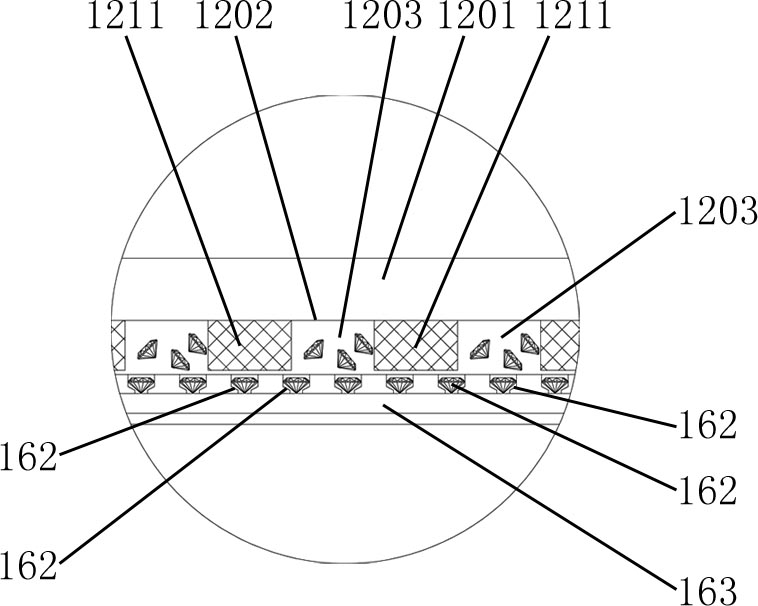

[0035] like Figure 1-Figure 5 As shown, a diamond-shaped product automatic arrangement and sorting machine includes a frame (not shown in the figure), an automatic material sorting device 1, a product detection device 2, an automatic sorting device 3, a first translation seat 4, and a Drive the front and rear translation mechanism 5, detection platform 6 and control device 7 of the first translation seat 4 to translate back and forth. The product detection device 2 and the automatic sorting device 3 are arranged sequentially from back to front and correspond to the position of the detection platform 6; The left and right translation mechanism 13, the rotating seat 14, the rotating mechanism 15 for driving the rotating seat 14 to rotate left and right of the feeder 12, the material receiving plate 11, the left and right translation mechanism 13, the rotating mechanism 15, the front and rear translation mechanism 5 and the lifting mechanism are all installed On the frame; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com