Micro-reaction channel structure, micro-reactor based on micro-reaction channel structure and nano material synthesis system

A technology of micro-reaction channels and micro-reactors, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve problems such as poor operability and long reaction distance, and achieve reduced dosage, enhanced mixing degree, and flow field The effect of complex and changeable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

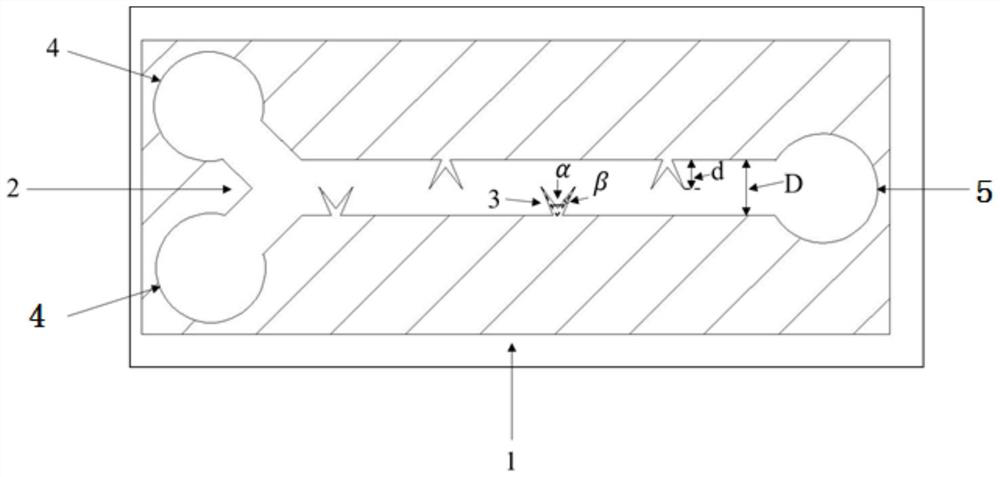

[0036] Such as figure 1 As shown, a micro-reaction channel structure includes a substrate 1 made of a glass sheet, a linear microchannel 2 with a characteristic size of 0.5 mm made of polydimethylsiloxane (PDMS), and a protruding inner wall of the microchannel 2 Four spiked microstructures 3, the spiked microstructures 3 are composed of two spikes gathered at the root, the spikes spread out in the circumferential direction, the opening and closing angle α of the spikes is 60°, and the longitudinal section shape of the spiked microstructures 3 is triangular , the shape of the longitudinal section of the root is polygonal; the vertex angle β of the spike section is 15°, the width d of the spike microstructure 3 is 1 / 2 of the width D of the microchannel, and they are staggered on both sides of the inner wall of the microchannel 2.

[0037] The microreactor composed of the above microreaction channel structure forms a Y shape between the two liquid inlets 4, and is provided with a...

Embodiment 2

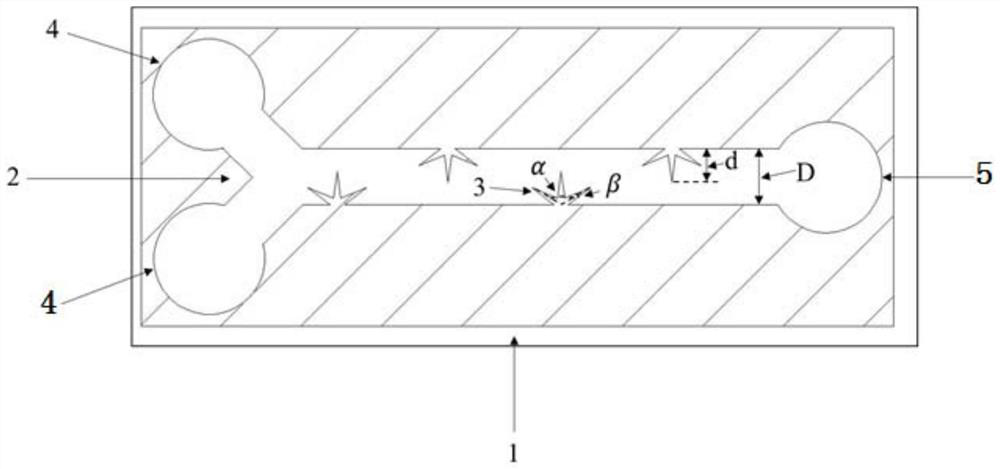

[0039] The micro-reaction channel structure of embodiment 2 is basically the same as the device system of embodiment 1, the difference is: as figure 2 As shown, the spike microstructure 3 is composed of three spikes gathered at the roots, the spikes spread out along the circumferential direction, and the opening and closing angle α of the spikes is 90°;

[0040] The micro-reactor composed of the above-mentioned micro-reaction channel structure is provided with two piezoelectric ceramic transducers as a hybrid strengthening module, and the two piezoelectric ceramic transducers are placed close to the microchannel 2, and the working of the piezoelectric ceramic transducers The frequency is 5kHz.

Embodiment 3

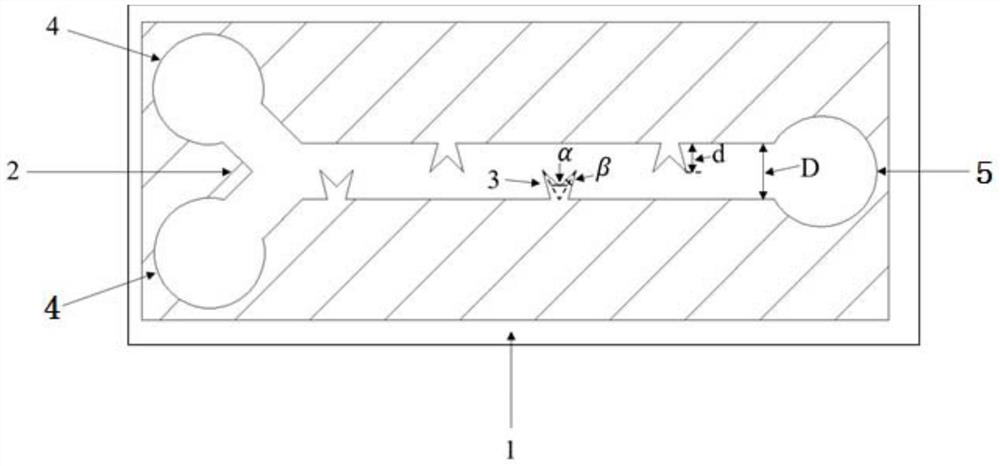

[0042] The micro-reaction channel structure of embodiment 3 is basically the same as the device system of embodiment 1, the difference is: as image 3 As shown, the vertex angle β of the spike section is 30°;

[0043] The micro-reactor composed of the above-mentioned micro-reaction channel structure is provided with three piezoelectric ceramic transducers as a hybrid strengthening module, and the three piezoelectric ceramic transducers are placed close to the microchannel 2, and the operating frequency of the piezoelectric ceramic transducers is 10kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com