Automatic preparation device for fluorescent material

A technology for automatic preparation and fluorescent materials, applied in the field of fluorescent materials, can solve problems such as waste of raw materials, waste of manpower and material resources, cumbersome operation, etc., and achieve the effects of avoiding difficult cleaning, reducing processing cycle and cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

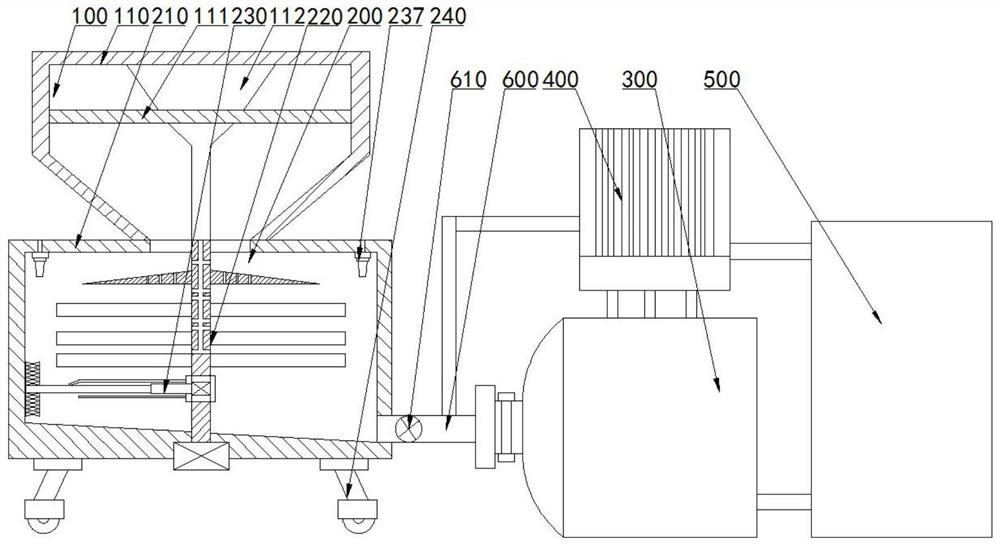

[0025] An automatic preparation device for fluorescent materials, comprising: a filter mechanism 100, a filler mechanism 200, a reaction kettle 300, a condenser 400 and a waste water processor 500;

[0026] The filter mechanism 100 includes: a funnel-shaped filter barrel 110 and an exhaust assembly arranged above the filter barrel 110; a filter screen 111 is provided in the filter barrel 110;

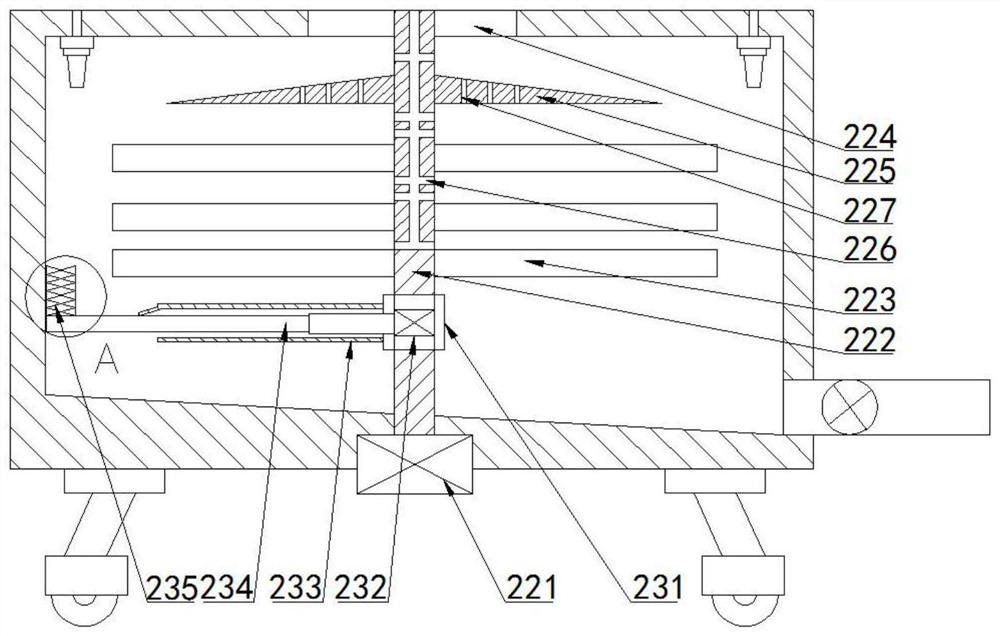

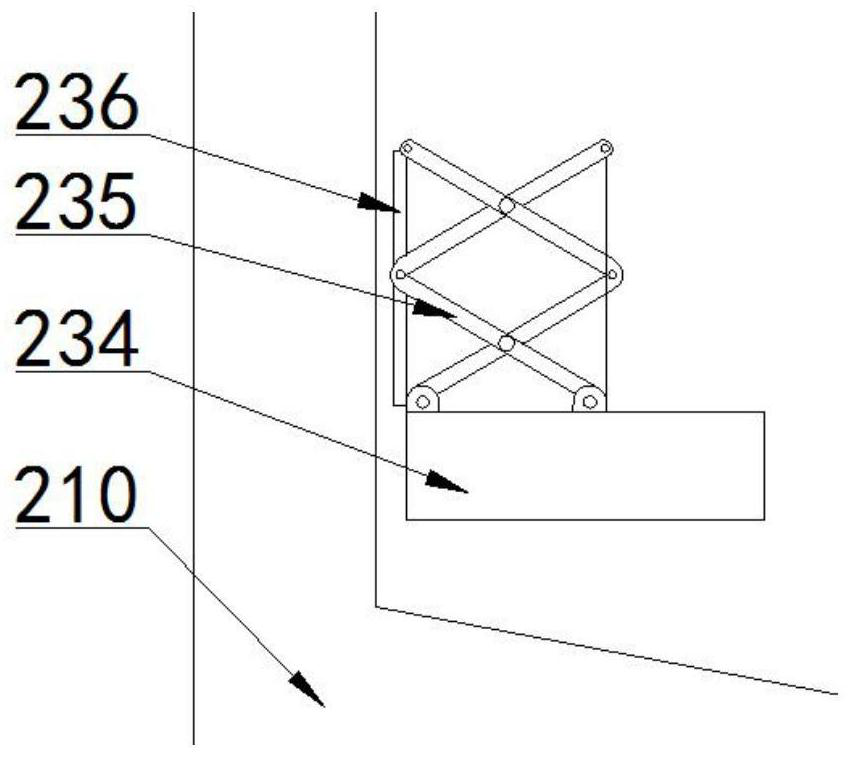

[0027] The filling mechanism 200 includes: a hollow filling bucket 210, a stirring assembly 220 and a cleaning assembly 230 arranged inside the filling bucket 210; The connected vertical rotating shaft 222 and the stirring rod 223 horizontally arranged on the rotating shaft 222; the driving motor 221 can drive the rotating shaft 222 to rotate; the cleaning assembly 230 is used to clean the inner wall of the stuffing bucket 210;

[0028] The stuffing bucket 210 is set as a hollow cylinder, the top of the stuffing bucket 210 is connected to the bottom of the filter bucket 110, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com