Shielding piece and electronic equipment

A technology of electronic equipment and shielding parts, applied in the field of electronic equipment, can solve the problems of increasing the impedance of conductive adhesive copper foil and affecting the radiation stray of terminal equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

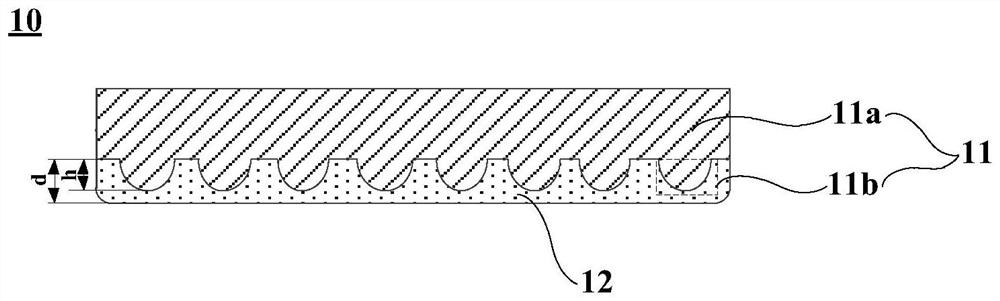

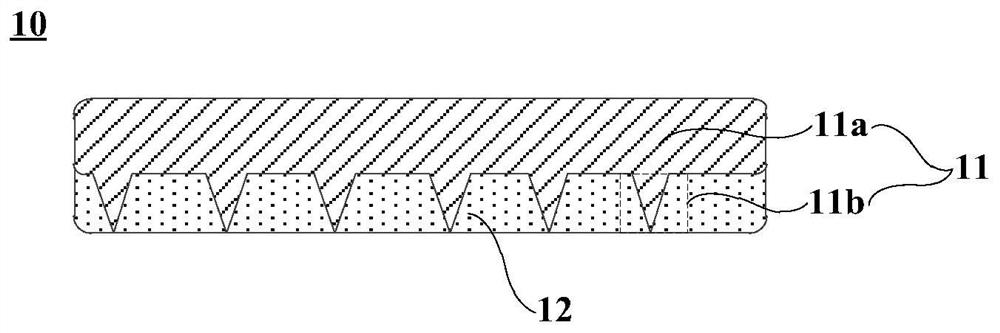

[0068] In addition, in some embodiments of the present application, after the conductive protrusions 11b are formed on the surface of the substrate of the conductive metal film 11 and before the adhesive 12 is applied, the manufacturing method of the shielding member 10 may further include: The surface of 11 is formed as Figure 9 The protective layer 13 shown in. The protective layer 13 can be, but not limited to, a conductive layer structure formed on the surface of the conductive metal film 11. An example is an electroplating layer formed on the surface of the conductive metal film 11. The material of the electroplating layer can be, but not limited to, gold, silver, Metals with strong oxidation resistance such as nickel. By arranging the protective layer 13 on the surface of the conductive metal film 11, the oxidation of the conductive metal film 11 can be effectively avoided, so that it has anti-oxidation and anti-corrosion capabilities, so as to prolong its service life...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com