Drum paper assembling method

An assembly method and drum paper technology, applied in the direction of sensors, electrical components, diaphragm structures, etc., can solve problems such as poor grip, waste of materials, and reduced product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

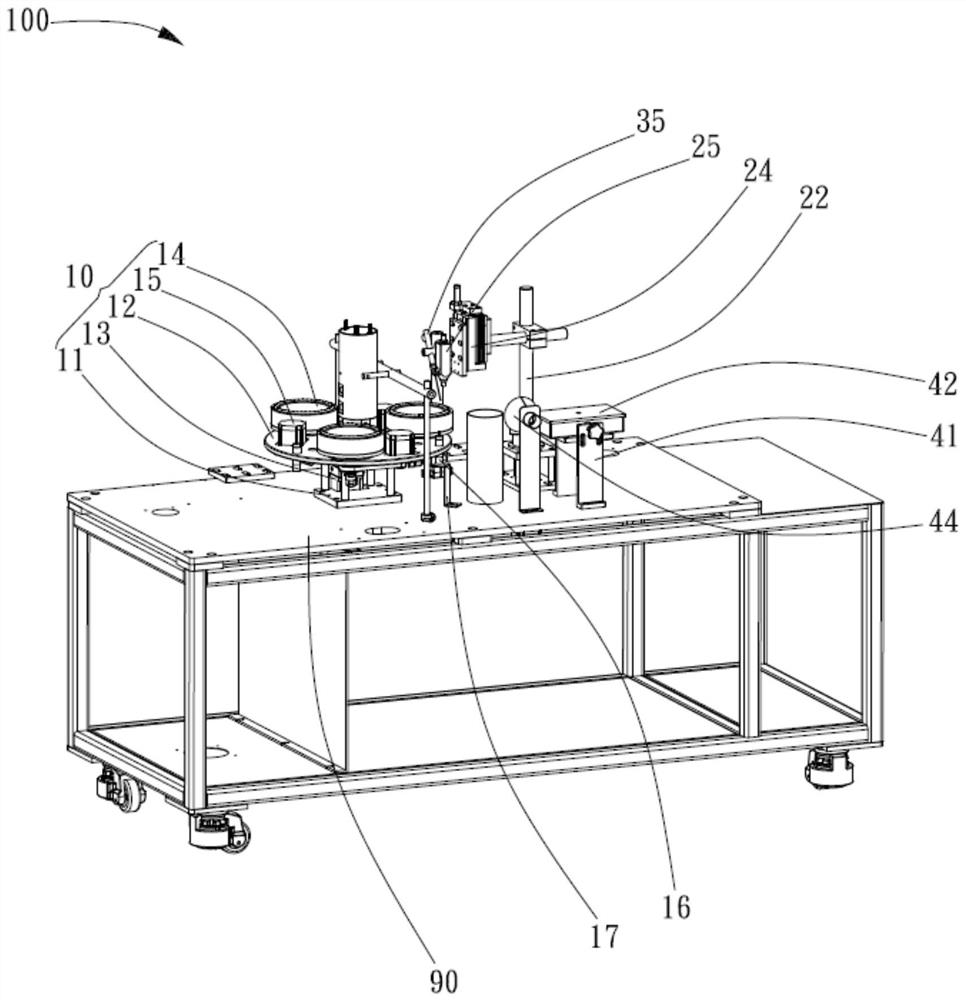

Image

Examples

Embodiment

[0029] The drum paper assembly method described in the embodiment of the present invention comprises the following steps:

[0030] S1, cutting the vibrating ring material into a ring-shaped body to obtain a ring-shaped material;

[0031] S2, the ring material is pasted on the outer edge of the drum paper carcass to obtain the assembly;

[0032] S3, the assembly is positioned at the center of the drum paper carcass, and the ring material of the assembly is formed to obtain a semi-finished product;

[0033] S4. Die cutting the edge of the semi-finished product to obtain a finished product.

[0034] When the ring material is formed, it is positioned with the center of the drum paper carcass. With the central positioning of the drum paper carcass, when the ring material is formed, the concentricity of the formed ring-shaped protrusion and the drum paper carcass can reach 100%, which can greatly improve the precision of the product.

[0035] The above-mentioned drum paper assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com