Extraction device for polypropylene synthesis and extraction method thereof

An extraction device, polypropylene technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of reducing work efficiency, injecting gas, laborious and laborious, etc., to improve work efficiency, save manpower, and fast packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

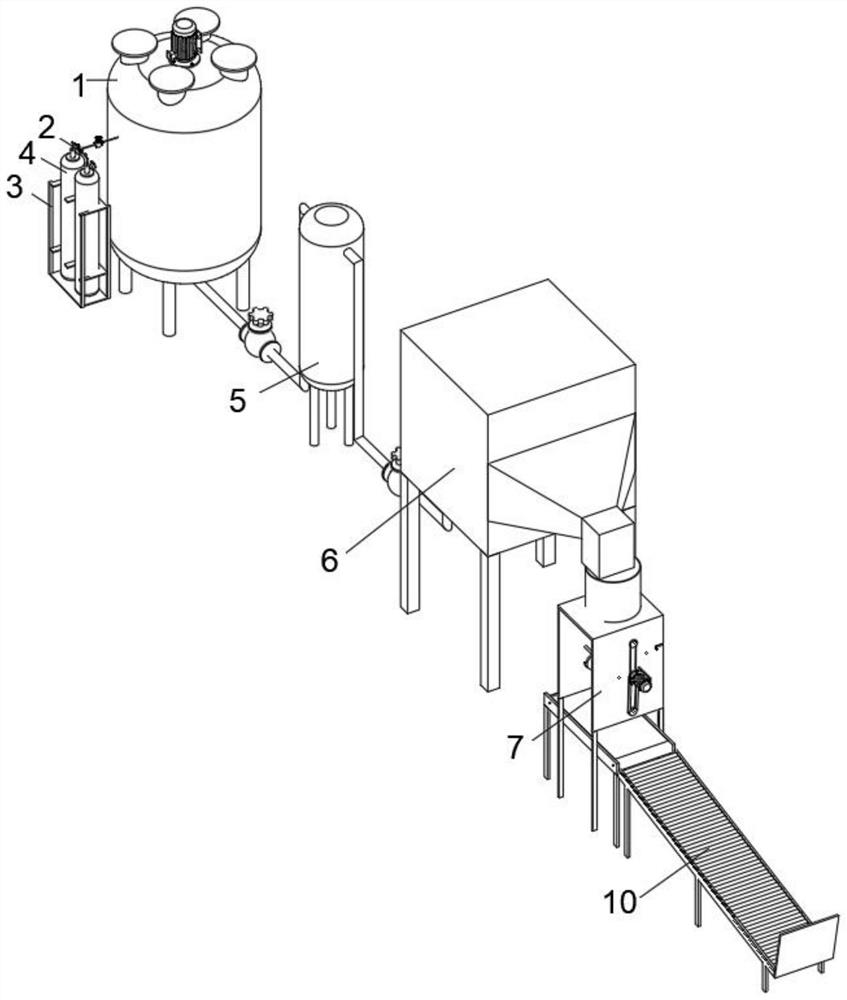

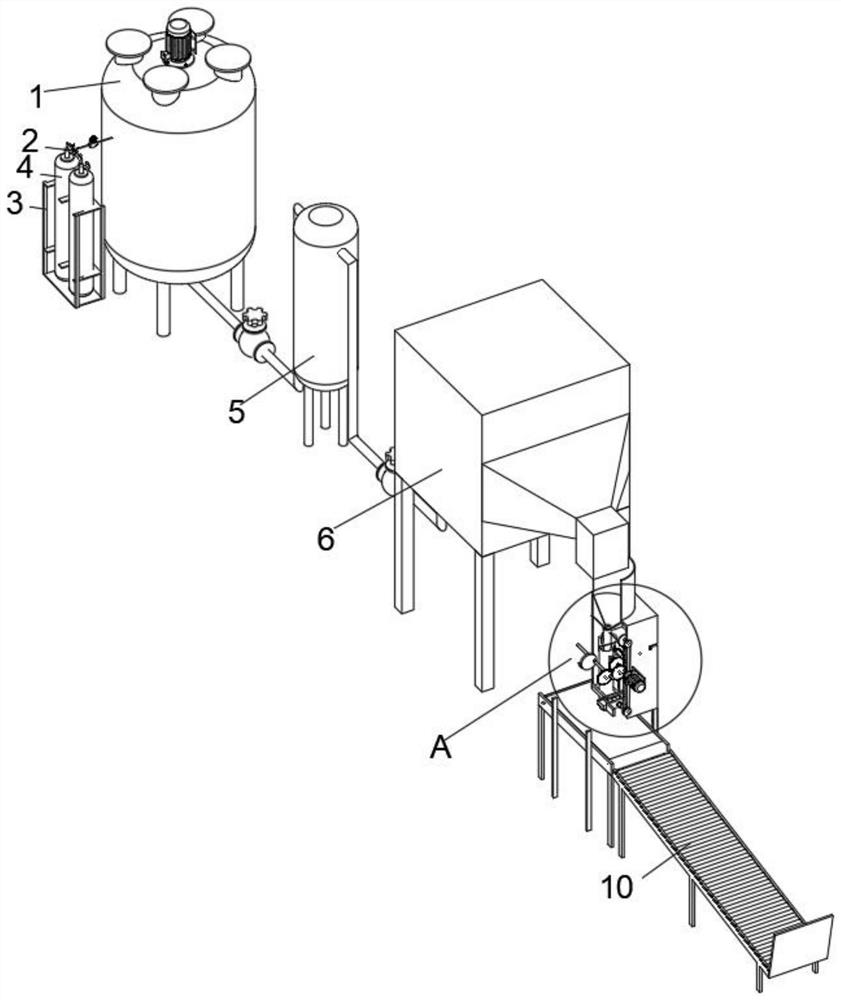

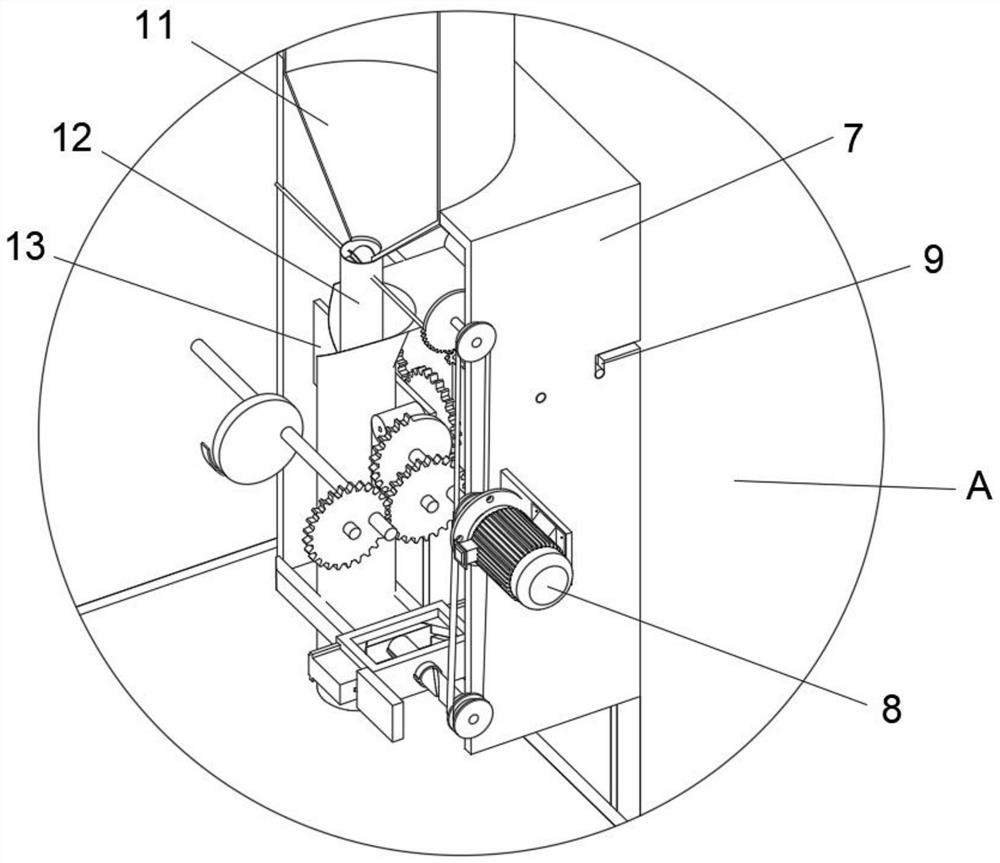

[0037] Example: such as Figure 1-8 As shown, the present invention provides an extraction device for polypropylene synthesis, comprising a reactor main body 1, a control assembly 2 is provided on one side of the reactor main body 1, a bracket 3 is provided below the control assembly 2, and the inside of the bracket 3 is fixed There are two gas storage tanks 4, the other side of the reactor main body 1 is provided with a separator main body 5, one side of the separator main body 5 is provided with a granulator main body 6, and the lower part of the granulator main body 6 is provided with a mounting frame 7 , the outer side of the mounting frame 7 is fixed with a packaging component 8, and the inside of the mounting frame 7 is provided with a draw-in slot 9 in an L-shaped structure. 11. The lower end of the hopper 11 is welded with a material pipe 12, and the inner side of the mounting frame 7 is welded with a mounting plate 13;

[0038] When the air storage tank 4 on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com