Preparation method of hemostatic patch

A technology of hemostatic patch and thrombin, which is applied in pharmaceutical formulations, devices for coating liquid on surfaces, coatings, etc., can solve problems such as waste of suspension, and achieve the effects of strong adhesion, good hemostatic effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of hemostatic patch provided by the present invention, comprises the following steps:

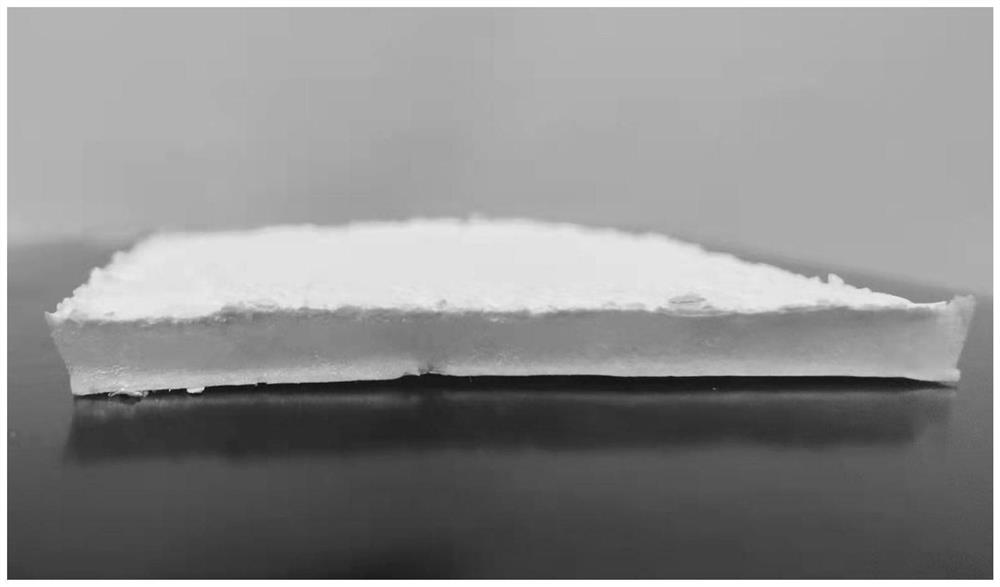

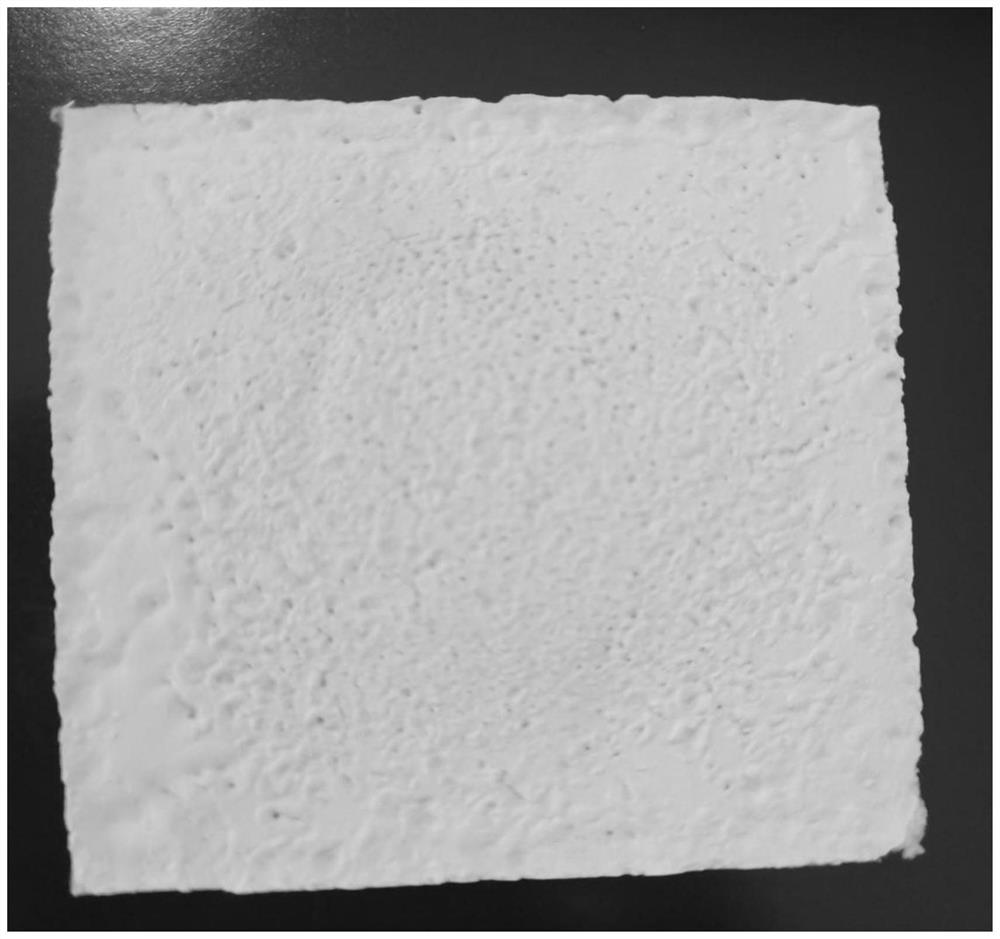

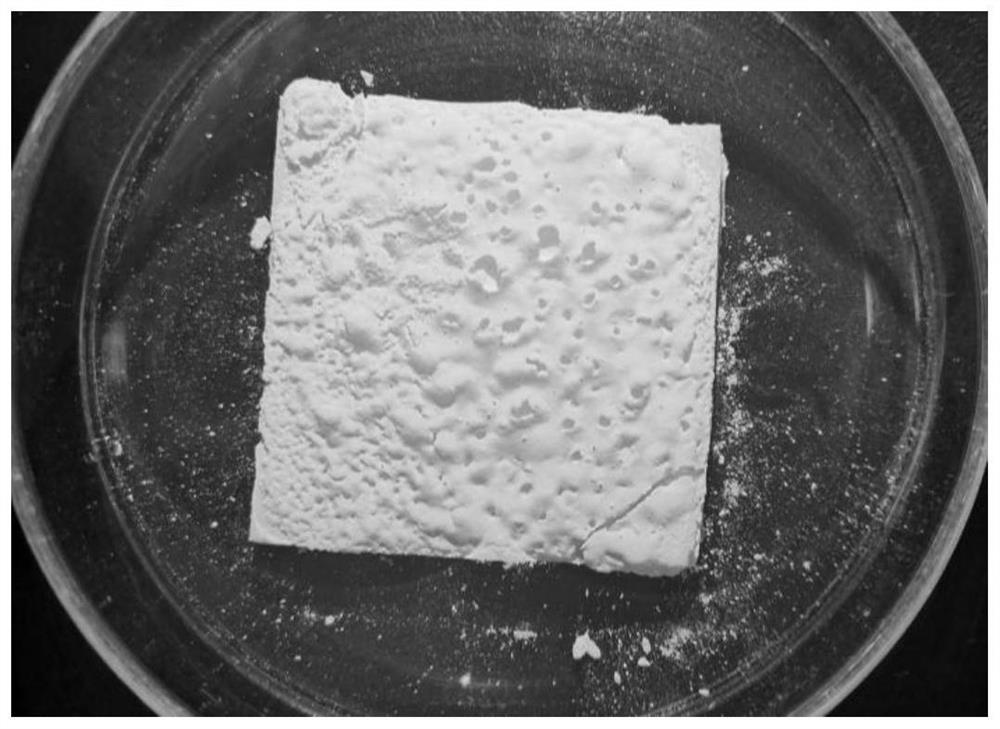

[0027] (1), take a small amount of bovine collagen in the mold, and scrape it flat with a collagen scraper, so that the collagen forms a collagen layer with a thickness of 0.3-0.5cm on the mold; after removing the excess bovine collagen, press the film Paste the film on the surface of the scraped collagen layer. During the pasting process, avoid large air bubbles between the film and the collagen layer. Finally, freeze at 20-50°C for 19-23 hours, and remove the film. , The frozen collagen layer is used as the solid carrier of the hemostatic patch, also called collagen carrier.

[0028] (2) Mix fibrinogen, thrombin, calcium chloride and low-temperature absolute ethanol (pre-cooled at -20°C) to form a medicinal solution, and place it in a disperser (IKA, T 25 easy clean) for homogenization Stirring, the stirring speed in the process of homogenization is (1...

Embodiment 1

[0041] The preparation method of the hemostatic patch provided by the invention comprises the following steps:

[0042] (1) Put the square mold (made of medical grade PVC, size 4.9cm×4.9cm×1cm) into the 316 stainless steel liquid medicine tray, take a small amount of bovine collagen (transparent gel, do not process after purchase, use directly ) in the mould, scrape it flat with a collagen scraper (made of 316 stainless steel), so that the collagen forms a collagen layer with a thickness of 0.3-0.5 cm on the mould; Made of medical grade PVC) on the surface of the scraped collagen layer. During the pasting process, large air bubbles should be avoided between the pressure film and the collagen layer. 20°C gradient down to -50°C) freezing for 19-23h, peel off the pressure film, and the frozen collagen layer is used as the solid carrier of the hemostatic patch, also called collagen carrier.

[0043] Gradient freezing can specifically be as follows: the temperature drops from 20°C...

Embodiment 2

[0059] The present invention also prepared the following hemostatic composition examples, and verified the effect of the content of each substance in the hemostatic composition examples on the hemostatic patch through experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com