Radioactive waste resin wet oxidation device

A technology of radioactive waste resin and wet oxidation, applied in radioactive purification, feeding device, incinerator, etc., can solve the problems of waste compatibilization and insufficient long-term stability of solidified body, so as to prevent radioactive leakage and ensure clean discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the technical solutions in the embodiments of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of the embodiments.

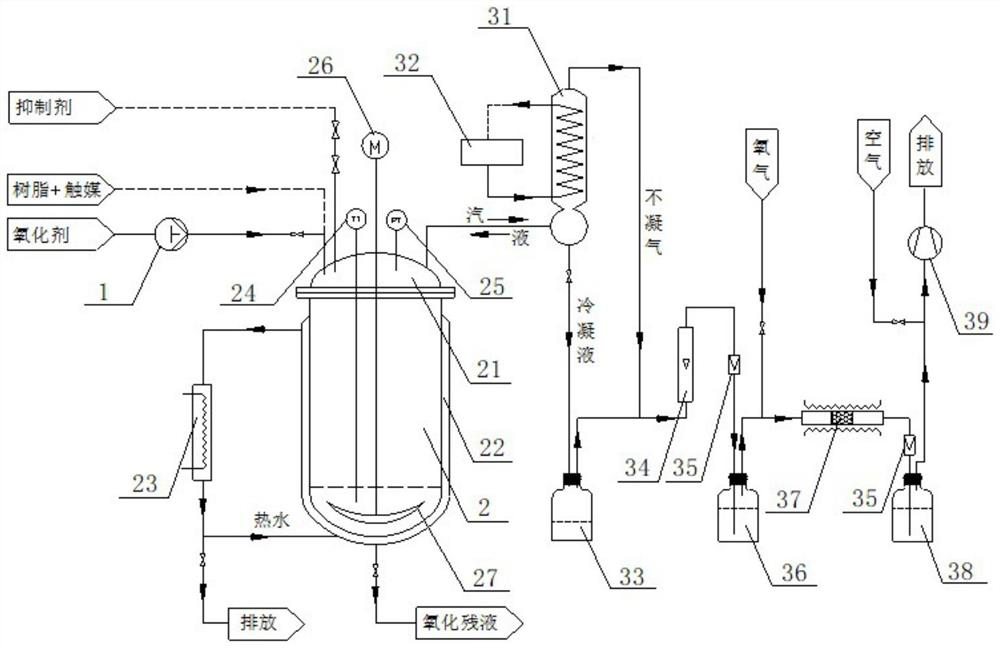

[0029] Such as figure 1 As shown, a radioactive waste resin wet oxidation device provided by an embodiment of the present invention includes a feed unit, an oxidative degradation unit, and a tail gas treatment unit; wherein,

[0030] (1) Feeding unit

[0031] The feeding unit includes a feeding mechanism and equipment for feeding materials such as waste resin, catalyst, inhibitor and oxidant into the reactor 2 .

[0032] In this embodiment, the waste resin and the catalyst solution are weighed and mixed in proportion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com