Welding spot quality identification method fusing knowledge graph and graph convolutional neural network

A convolutional neural network and knowledge graph technology, which is applied in neural learning methods, biological neural network models, character and pattern recognition, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

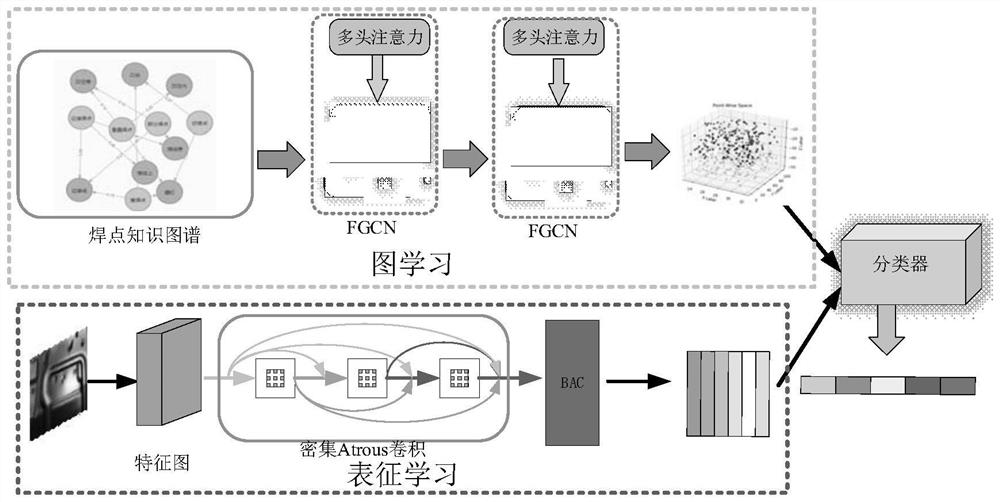

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

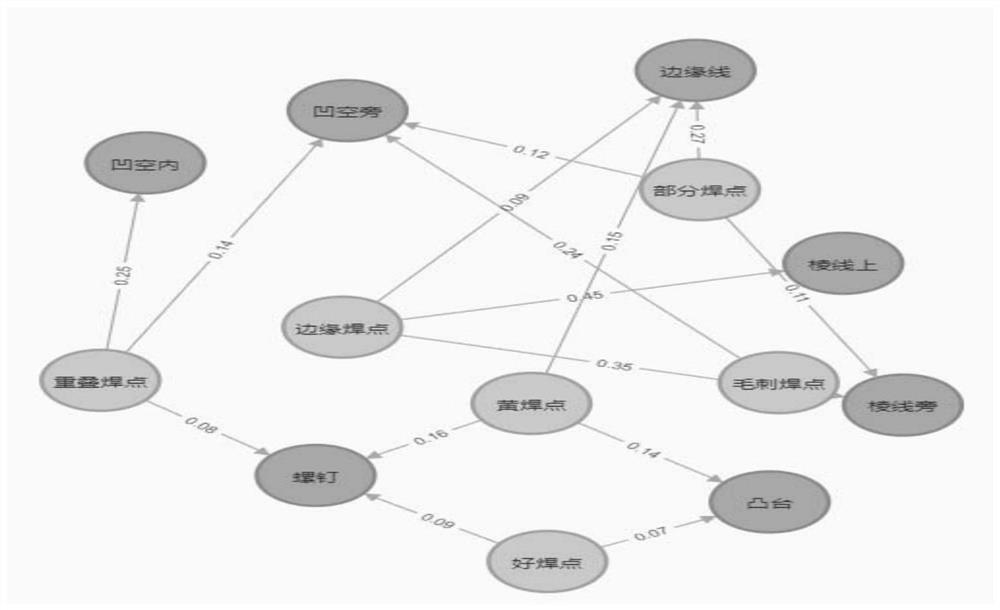

[0071] Taking the quality detection of automobile body solder joints as an example, the specific implementation of the method for identifying the quality of solder joints of the present invention that integrates knowledge graphs and graph convolutional neural networks will be described in detail.

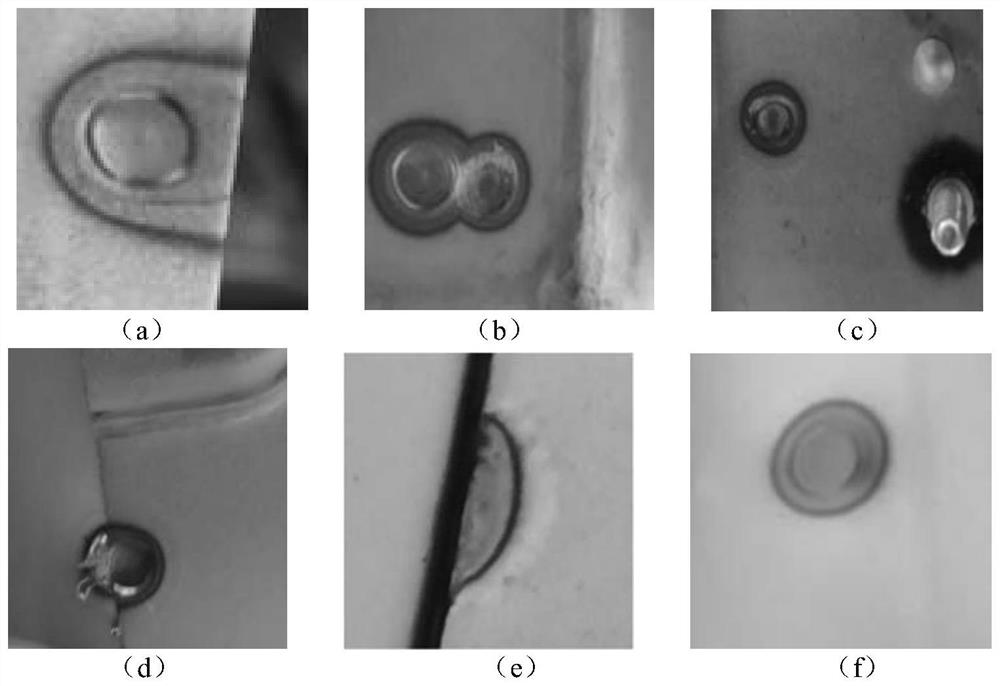

[0072] According to statistics, the appearance quality of spot welding joints is not only closely related to equipment status and process parameters, but also obviously related to the position of the welding joints on the body, such as figure 1 As shown, near the edge of the body, poor control of the position of the welding torch can easily lead to incomplete solder joints; near the boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com