Acoustic diagnosis method and device for crack fault of air inlet casing support plate of engine

A technology of air intake casing and diagnostic method, which is applied in the direction of measuring devices, scientific instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve accurate identification and efficient diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

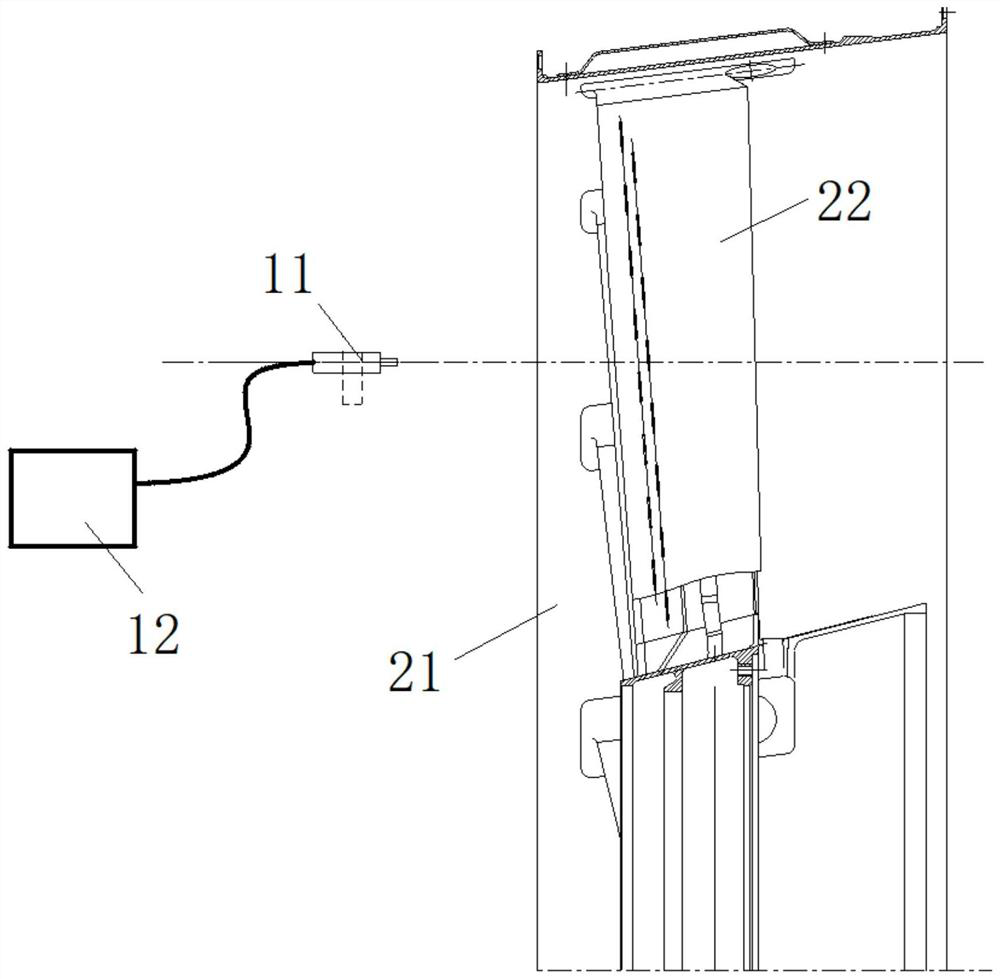

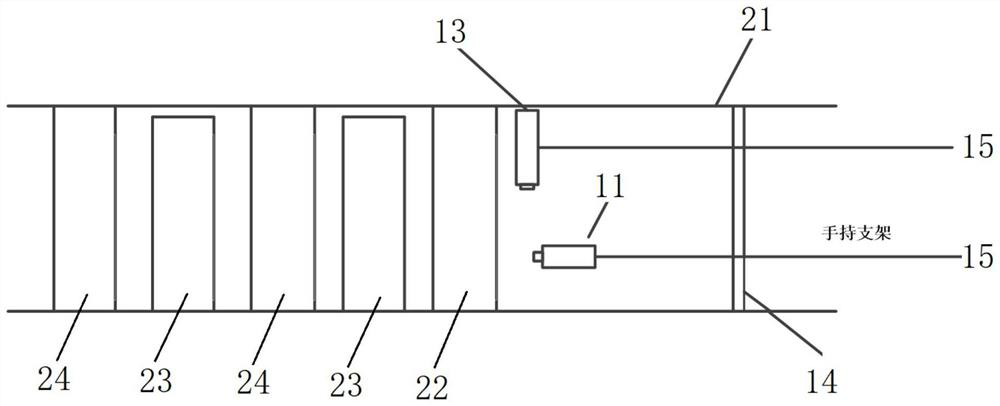

[0048] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0049] Aiming at the fault diagnosis of the fixed strut plate crack of the air intake casing of the aero-engine, this application proposes a crack fault acoustic diagnosis method and a fault diagnosis device, which can effectively, high-precision, and fast diagnose the fault of the intake casing strut plate crack identify.

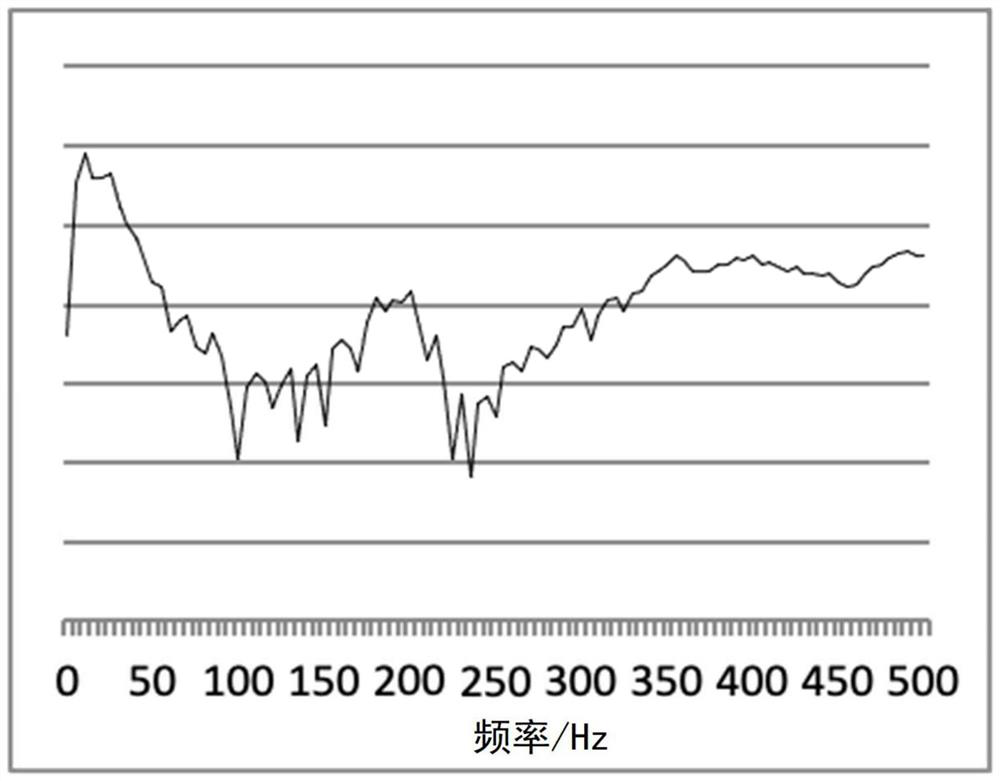

[0050] During the endurance test of the aero-engine, due to the long-term operation of the intake casing under high-speed and high-load test conditions, fatigue cracks will occur on the support plate, which seriously affects the test safety and engine reliability. The acoustic signal is a signal that can reflect the state information of structural characteristics. When a crack occurs in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com