Totally-closed low-speed permanent magnet direct drive system for electric gate valve

A permanent magnet direct drive, electric gate valve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of gate valve stroke limitation, large starting current, polluted medium, etc., to ensure accuracy and reliability, and reduce work Energy consumption, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

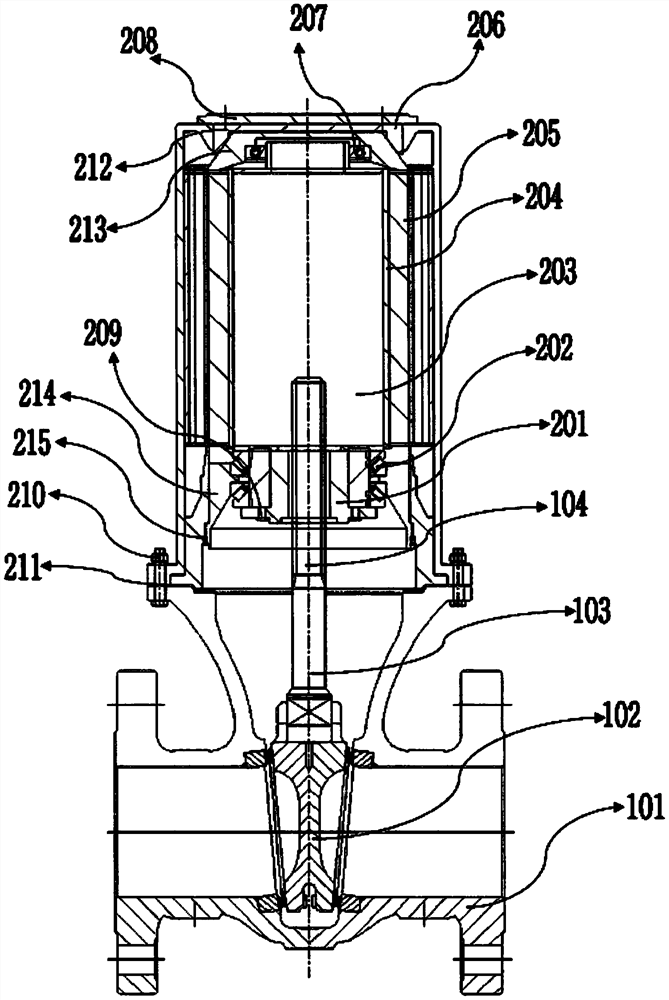

[0030] As shown in the accompanying drawings, a fully enclosed low-speed permanent magnet direct drive system for an electric gate valve according to the present invention includes a casing assembly, a stator 205, a non-magnetic shielding casing 204, a rotor assembly 203 and a control assembly, and the stator 203 is embedded in the In the casing assembly, the outer wall of the stator 203 is close to the inner wall of the casing shell 206, and the position of the stator 203 is limited by the shoulder of the non-magnetic shielding shell; the non-magnetic shielding shell 204 is located between the stator 205 and the rotating assembly, and is fixed on the casing The housing 206 shields the rotor assembly and the lead screw 104 inside its cavity. The rotor assembly transmits the torque to the lead screw 104 connected above the gate 102 through the screw nut 201, which drives the gate 102 to move up and down along the axis of the rotor assembly. The entire movement process uses a PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com