Cloth dyeing equipment with automatic supply function

A technology for dyeing equipment and fabrics, which is applied in the directions of processing textile material equipment configuration, textile material processing, processing textile material carriers, etc., can solve the problems of easy printing marks, dye deposition, uneven dyeing of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

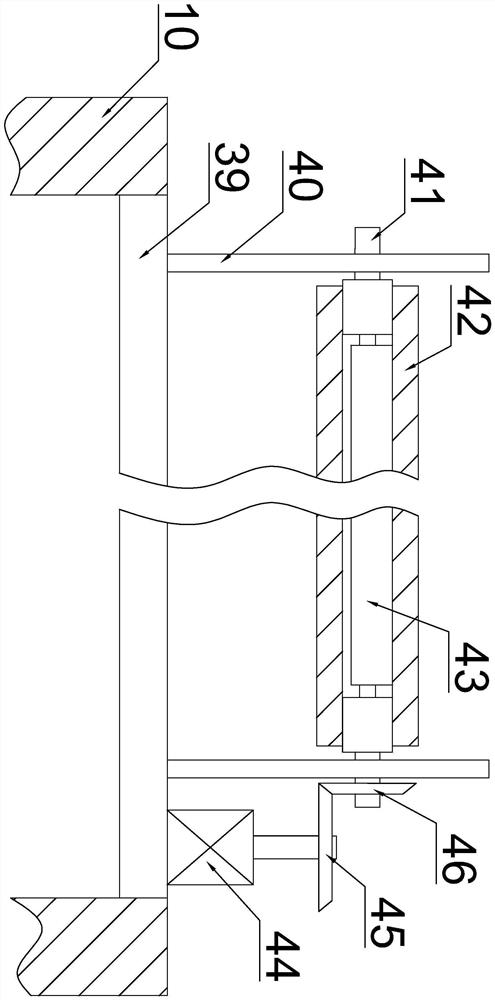

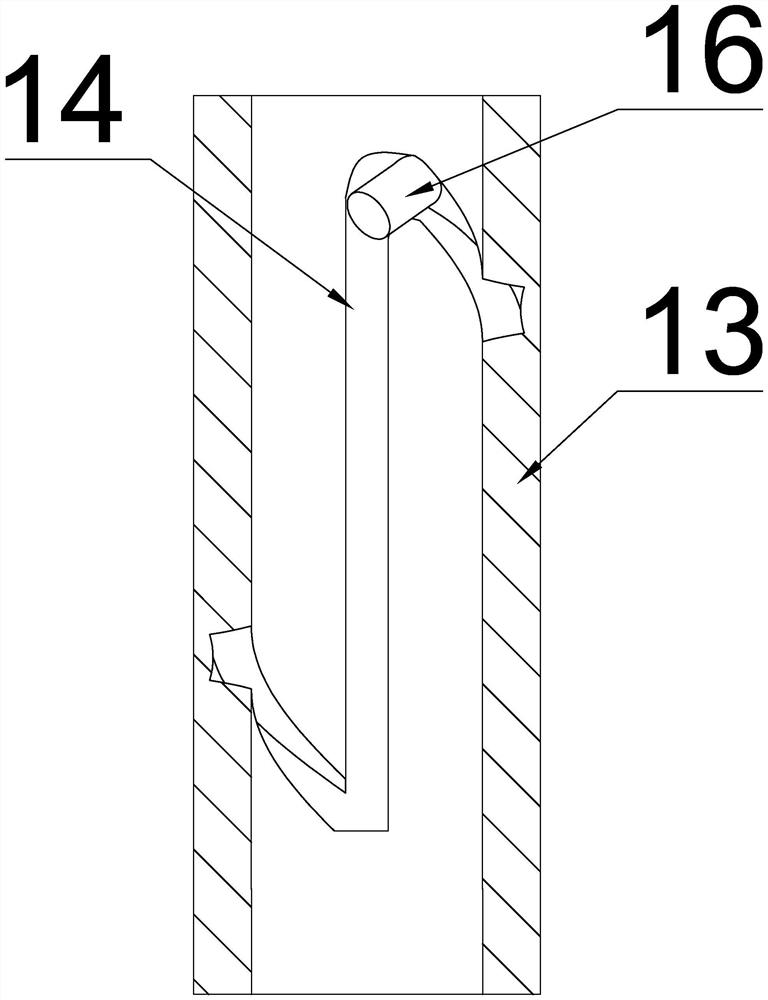

[0023] Such as figure 1 , image 3 , Figure 7 As shown, an automatic replenishment cloth dyeing equipment includes a casing 10, and a circulation device is provided at the bottom of the casing 10. The circulation device is used to circulate the dye solution in the dyeing chamber to avoid dye deposition. The circulation device includes the inside of the casing 10. There is a dipping chamber 55, the bottom of the dipping chamber 55 is provided with a circulation port 11, a circulation support 12 is fixed on the inner wall of the circulation port 11, and a rotating drum 13 is installed in the middle of the circulating support 12, and a circulating tank 14 is provided on the inner wall of the rotating drum 13 The circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com