Novel case unpacking machine for large-capacity beverage production line

A large-capacity, production line technology, applied in the direction of packaging machines, types of packaging items, packaging bottles, etc., can solve the problems of low production efficiency and lack of special unpacking machines, and achieve the goal of improving production efficiency, simple and reliable structure, and increasing the degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

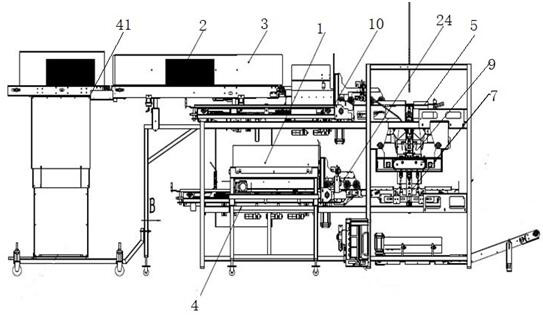

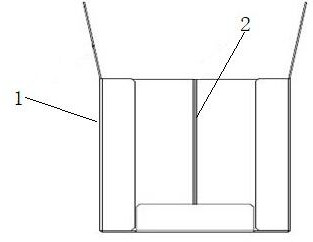

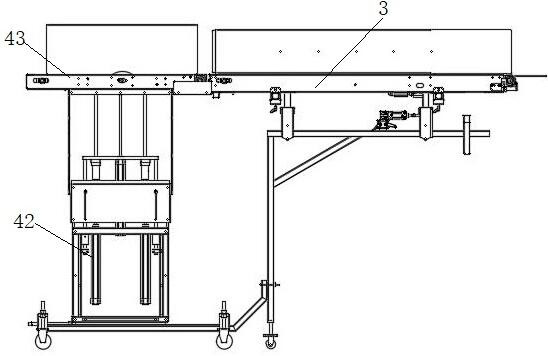

[0036] Such as figure 1 Shown is a new type of large-capacity beverage production line unpacking machine disclosed by the present invention. The structure of the H-shaped partition type fixed carton is as follows: figure 2 As shown, it includes the main board 1 and the H partition 2, and the unpacking machine includes the main board feeding device 3 for the feeding and transmission of the main board 1, and the partition feeding device for the material feeding and transmission of the H partition 4. Set the H clapboard material folding mechanism 5 at the outlet of the clapboard feeding device 4, and the first hot melt glue gun 6 for spraying hot melt glue on the folding surface of the H clapboard material; The main body plate folding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com