Automatic unpacking and feeding method based on vibration removal method

A material package and residual material technology, which is applied in the field of automatic unpacking and feeding based on vibration removal of residual material, can solve the problems of residual material waste, incomplete material falling, and incomplete material falling, so as to prevent raw material waste and improve Efficiency, no residue blanking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

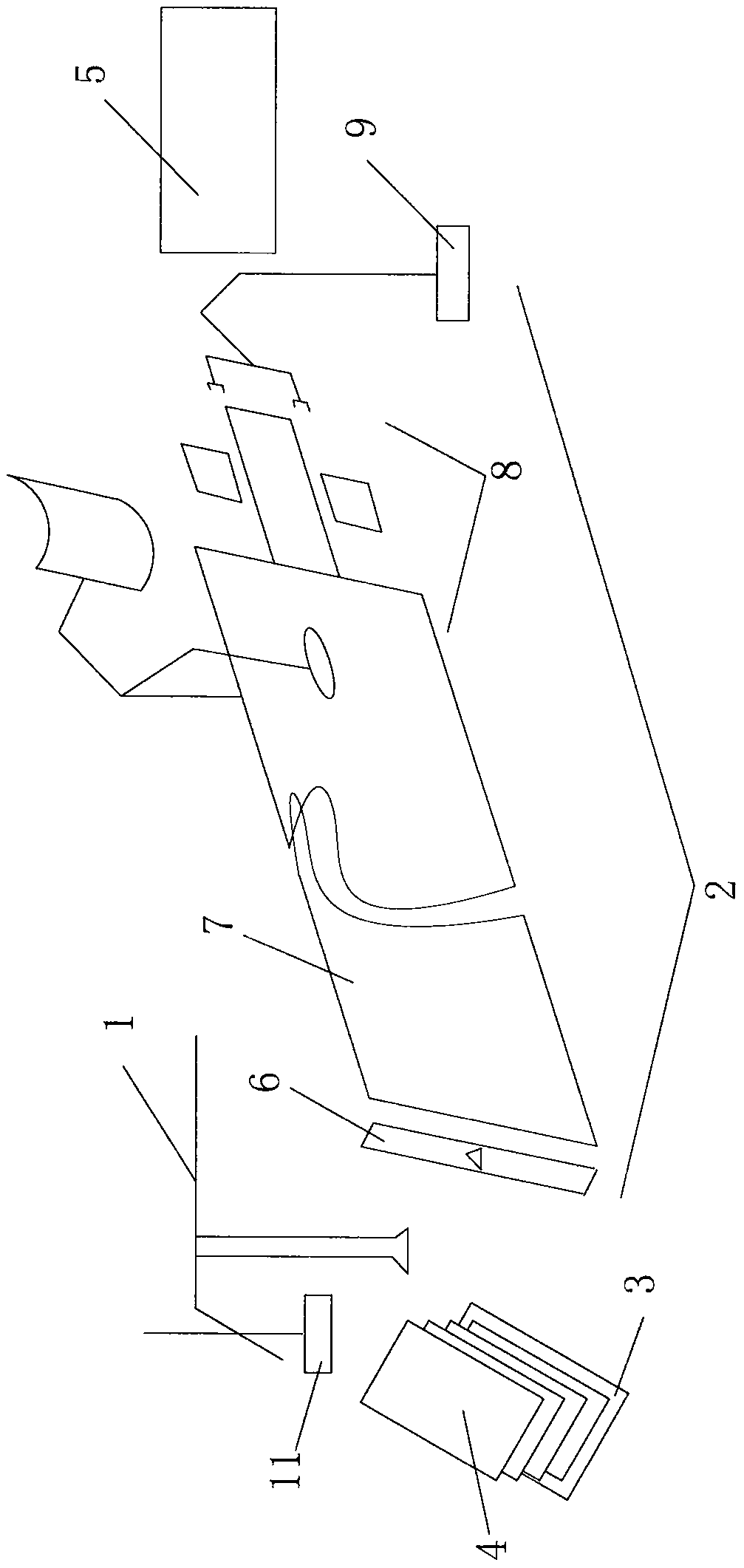

[0048] Such asfigure 1 As shown, the present invention is based on an automatic unpacking and feeding device, which includes: a bag moving machine 1, an unloading mechanism 2, a bag receiving mechanism 5, a material bag rack 3 and a controller, and a collector is arranged below the unloading mechanism to collect materials Finally, it is fed into the production machinery through the feeding pipeline.

[0049] The bag moving machine 1 is a Cartesian robot with a vacuum suction cup 11 at its end. A liftable base is installed at the bottom of the material bag rack 3. After each bag is moved, the controller controls the base to rise by one grid, so that the bag moving machine 1 does not need to change the operating height, just repeat the handling track.

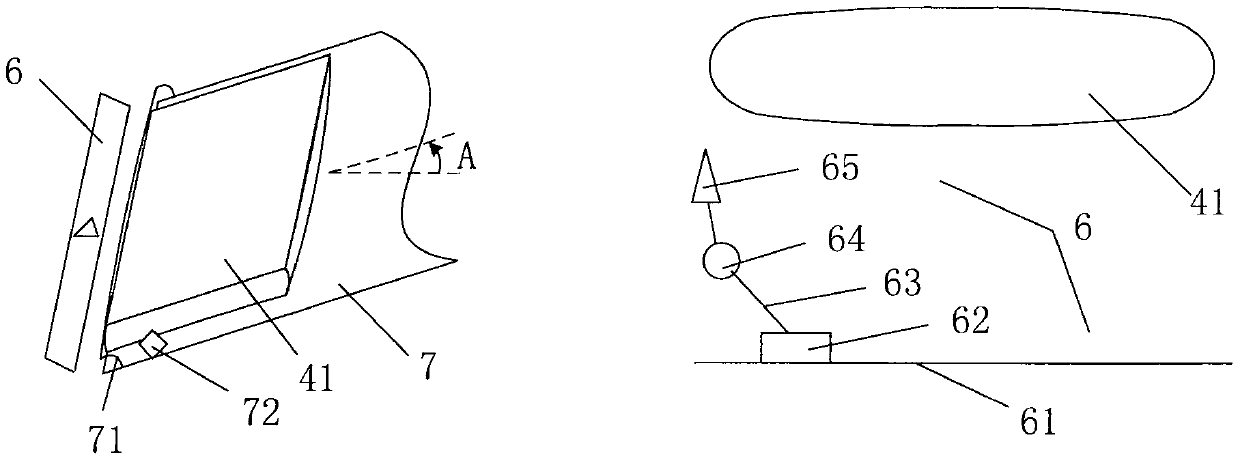

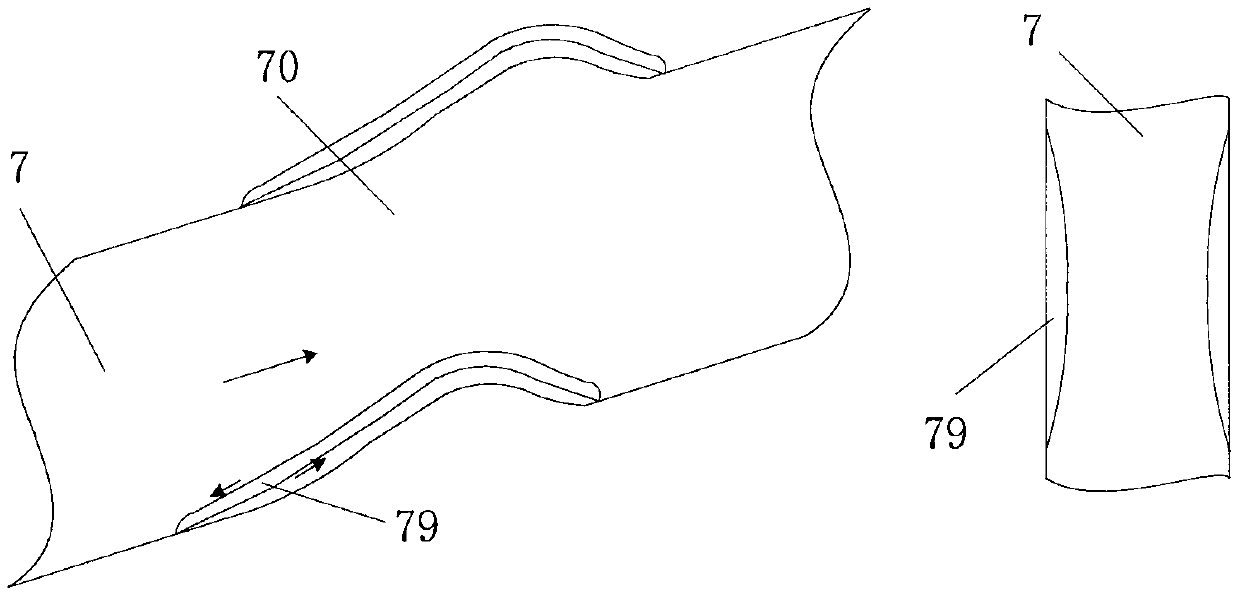

[0050] see Figure 1-7 , The unloading mechanism 2 includes a cutting mechanism 6, a conveyor belt 7 with an upwardly inclined surface, a vibration bag mechanism 8 and a bag pulling robot 9 arranged in sequence.

[0051] Cuttin...

Embodiment 2

[0060] combine Figure 9 As shown, the device of the present invention comprises: a bale-handling machine, a material unloading mechanism, a bag receiving mechanism, a material bag rack and a controller, and the unloading mechanism includes a cutting mechanism 6, a conveyer belt 7, a vibrating bag mechanism and a bag-pull manipulator 9 (as a bag-pull mechanism ). The conveyor belt 7 rear end is vertically downward, and there is also a vertical cutting bag storehouse 78 at the bottom of the conveyor belt 7 rear end. There is an opening in the lower part of the bag cutting bin 78, and the cutting knife 65 in the cutting mechanism 6 passes through the opening and cuts the material bag 41 straight. The vibrating package mechanism includes a vibrator 80 and a frame 81. The vibrator 80 includes a left vibrating frame 84 and a right vibrating frame 85 with a groove-shaped vibrating head at the top. A racket head 82 and a right racket head 83. Rotating the racket rotating shaft 86 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com