Gel injection rate adjusting device

A technology of rate adjustment and glue injection device, which is used in mixers with rotary stirring devices, packaging, transportation and packaging, etc., can solve the collision between the bottle mouth of the glue injection bottle and the glue injection mouth, the low adaptability of the device, and the tipping of the support plate. and other issues to achieve the effect of reducing economic losses, increasing the scope of application, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

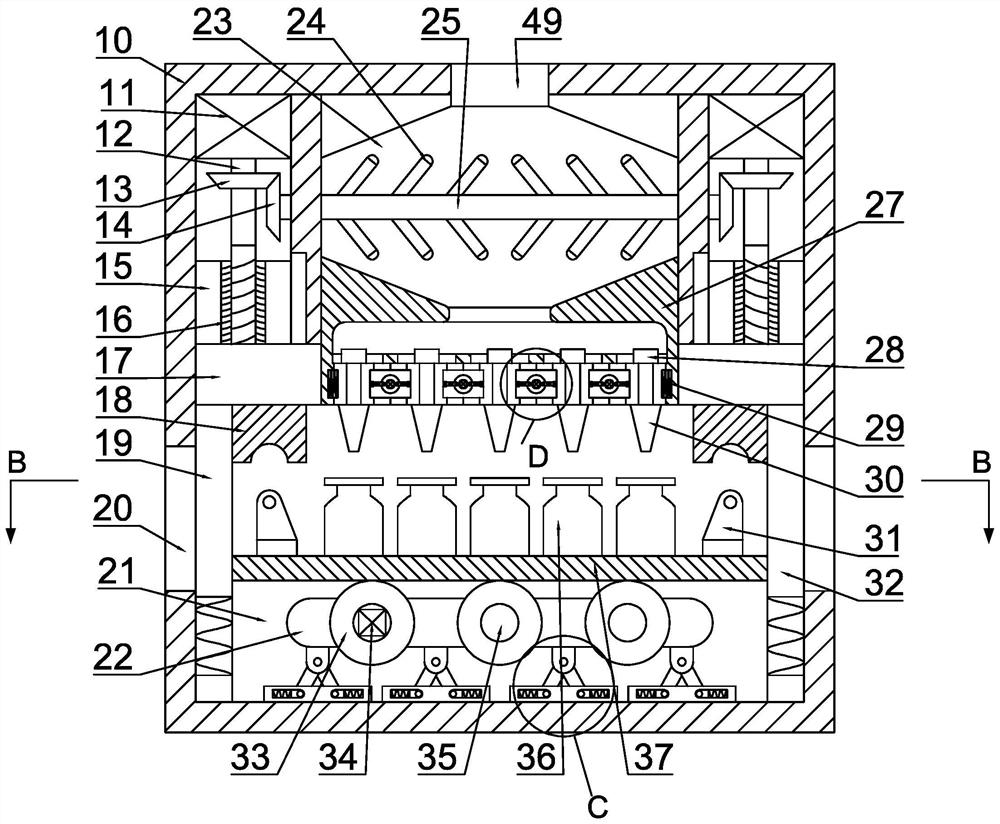

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

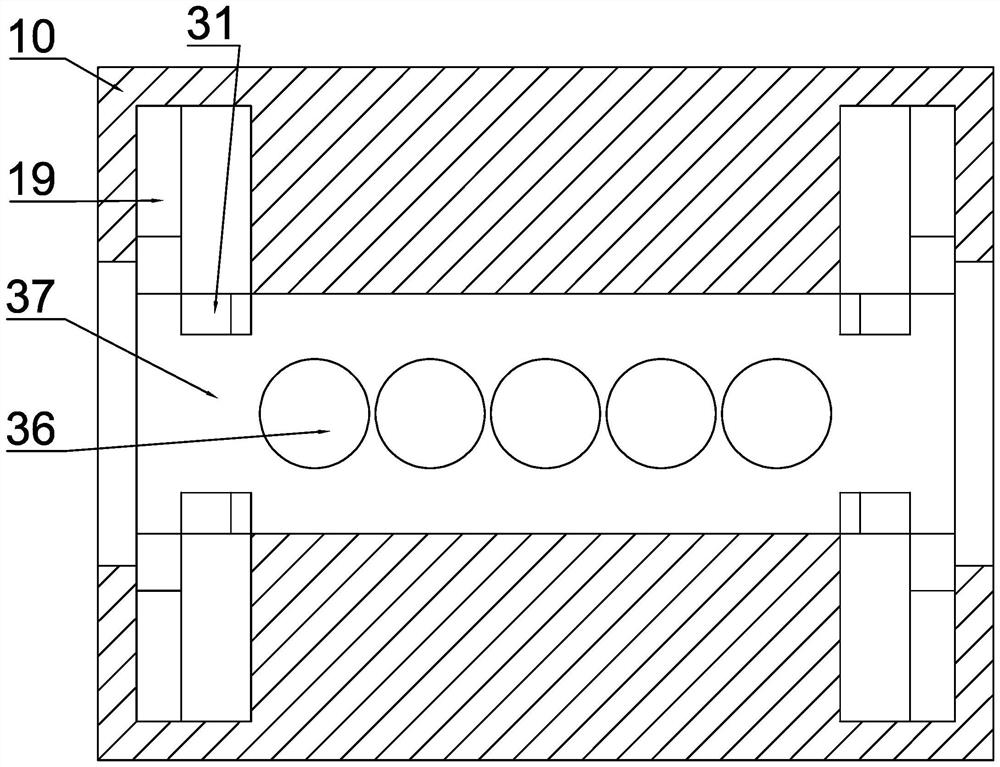

[0027] Such as figure 1 As shown, a speed regulating device for gel injection includes a housing 10, the housing 10 includes the housing 10, the upper side of the housing 10 is provided with a glue injection chamber 23, and the glue injection chamber 23 is provided with a glue injection chamber. The glue injection device is used for the glue injection of the gel. The glue injection device includes two glue injection motors 11 fixed on both sides of the glue injection cavity 23. The output end of each glue injection motor 11 is fixedly equipped with a glue injection shaft 12, and the shell Sliding blocks 15 are provided on both sides of the body 10, and an engaging block 16 is fixed inside each sliding block 15, and each en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com