Processing technology for manufacturing spectacle lens from PLA (polylactic acid) particles

A processing technology and spectacle lens technology, applied in the field of spectacle lenses, can solve the problems of lens pollution, no use of PLA particles, non-environmental protection, etc., and achieve the effects of environmental protection, good production effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

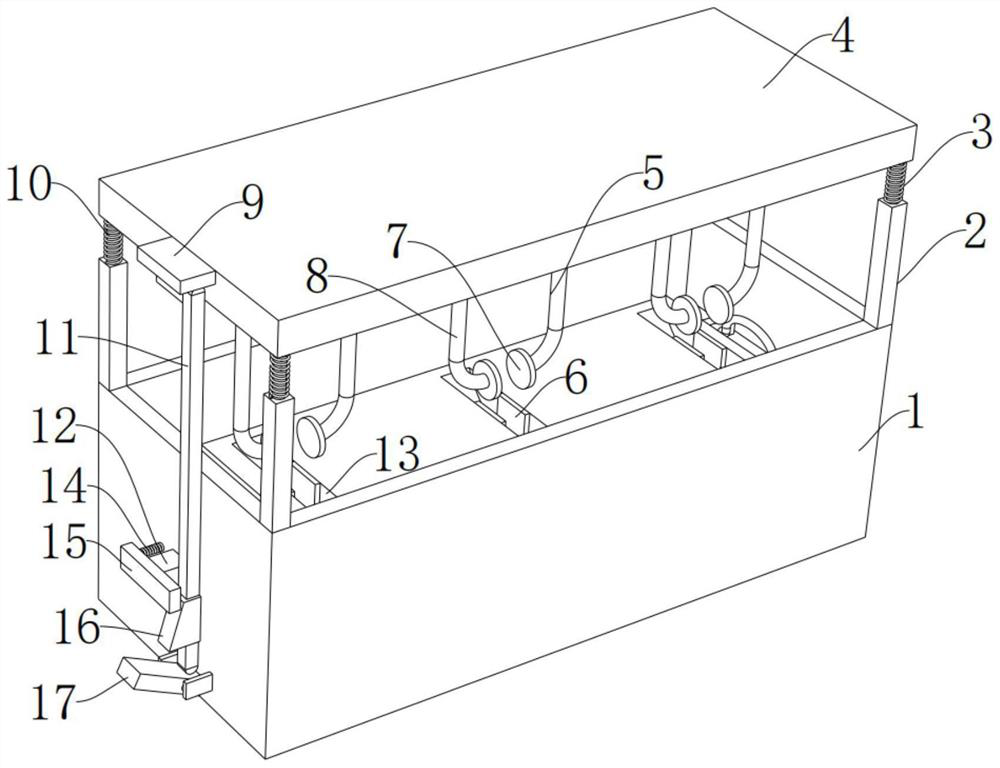

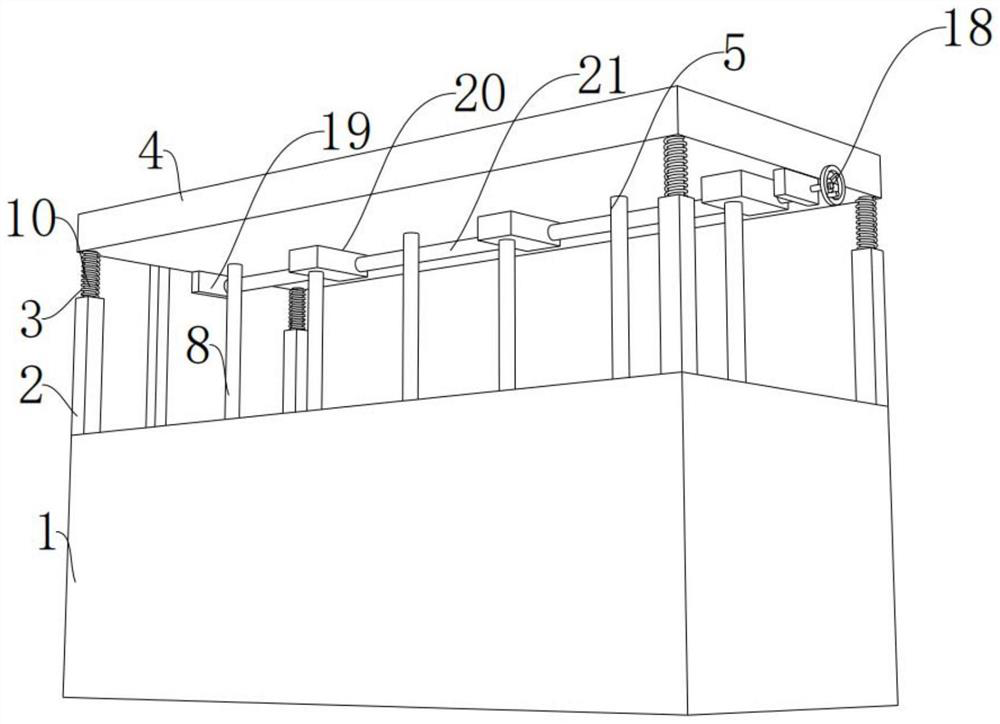

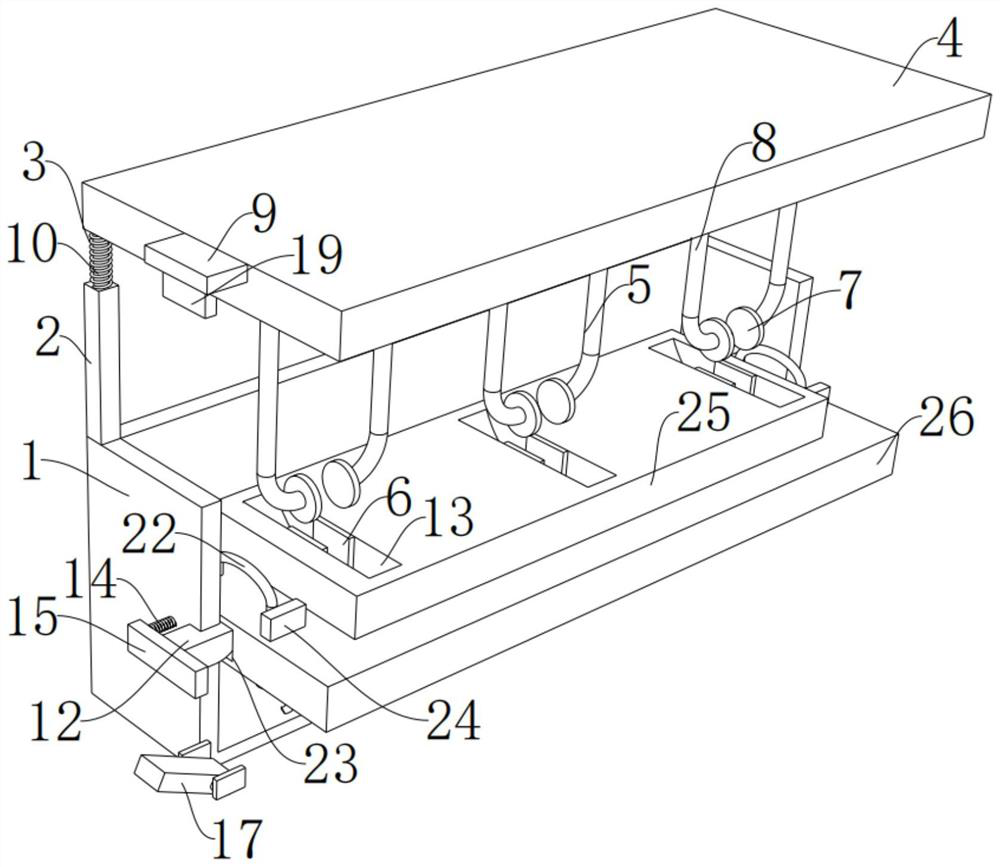

[0041] refer to Figure 1-4 , the processing technology that PLA particle is made spectacle lens, comprises the following steps:

[0042] S1. Preheating and drying:

[0043] S11, put the PLA particles into a mixer or a vibration box;

[0044] S12. Use a dryer to dry the moisture in the PLA granules, and appropriately increase the drying time, which can reduce the time required for the PLA granules to melt and improve work efficiency;

[0045] S2, melting:

[0046] S21, transporting the dried PLA particles to the extrusion screw, the extrusion screw is covered with an electric heating coil, and the PLA particles are heated until they are completely melted;

[0047] S22, transporting the melted PLA to the injection mold through the extrusion screw;

[0048] S3. Injection molding:

[0049] S31, the first stage of injection, the injection volume accounts for 65% of the mold;

[0050] S32, the second stage of injection, the injection volume accounts for 20% of the mould;

[...

Embodiment 2

[0057] refer to Figure 1-4 , the processing technology that PLA particle is made spectacle lens, comprises the following steps:

[0058] S1. Preheating and drying:

[0059] S11, put the PLA particles into a mixer or a vibration box;

[0060] S12. Use a dryer to dry the moisture in the PLA particles, appropriately increase the drying time, the drying time is 2 hours, and the drying temperature is 50°C, which can reduce the time required for the PLA particles to dissolve and improve work efficiency;

[0061] S2, melting:

[0062] S21. Transporting the dried PLA particles to the extrusion screw, the extrusion screw is covered with an electric heating coil, and the temperature is 220°C, and the PLA particles are heated until they are completely melted;

[0063] S22, transporting the melted PLA to the injection mold through the extrusion screw;

[0064] S3. Injection molding:

[0065] S31, the first stage of injection, the injection volume accounts for 65% of the mold, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com