Wooden ship seam twisting method

A wood and gap technology, applied in the field of wooden boats, can solve the problems of water ingress and water leakage, and achieve the effects of avoiding water seepage, low corrosion resistance and reducing water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

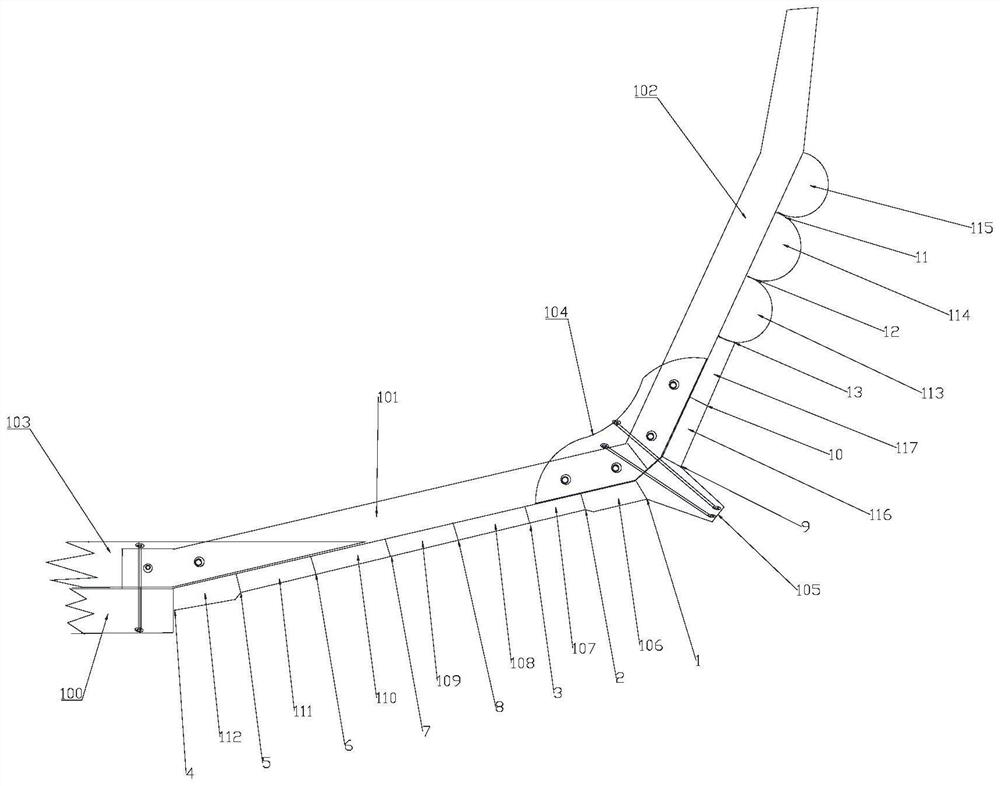

[0055] The caulking method for wooden boats provided by the present invention is suitable for untwisted boats or wooden boats with clean gaps, and includes a keel 100, and rib bottom beams 101 and rib side beams 102 are sequentially connected to the two ends of the keel 100. A bottom beam connecting material 103 is connected between the rib bottom beam 101 and the keel 100 , and a bracket plate 104 is connected between the rib bottom beam 101 and the rib side beam 102 .

[0056] Stabilizer fins 105 are provided on the outside of the connection between the rib bottom beam 101 and the rib side beam 102 , and a first bottom plate 106 , a second bottom plate 107 , and a second bottom plate 106 are arranged between the stabilizer fins 105 and the keel 100 Three base plates 108, fourth base plates 109, fifth base plates 110, aileron plates 111 and keel wing plates 112, first base plates 106, second base plates 107, third base plates 108, fourth base plates 109, fifth base plates 110,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com