Production method for efficiently producing high-strength bolt

A technology of high-strength bolts and production methods, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of substandard strength, no thread strengthening of thread rolling machine, and decline in anti-wear effect, so as to improve structural strength , Guarantee the effect of anti-corrosion and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

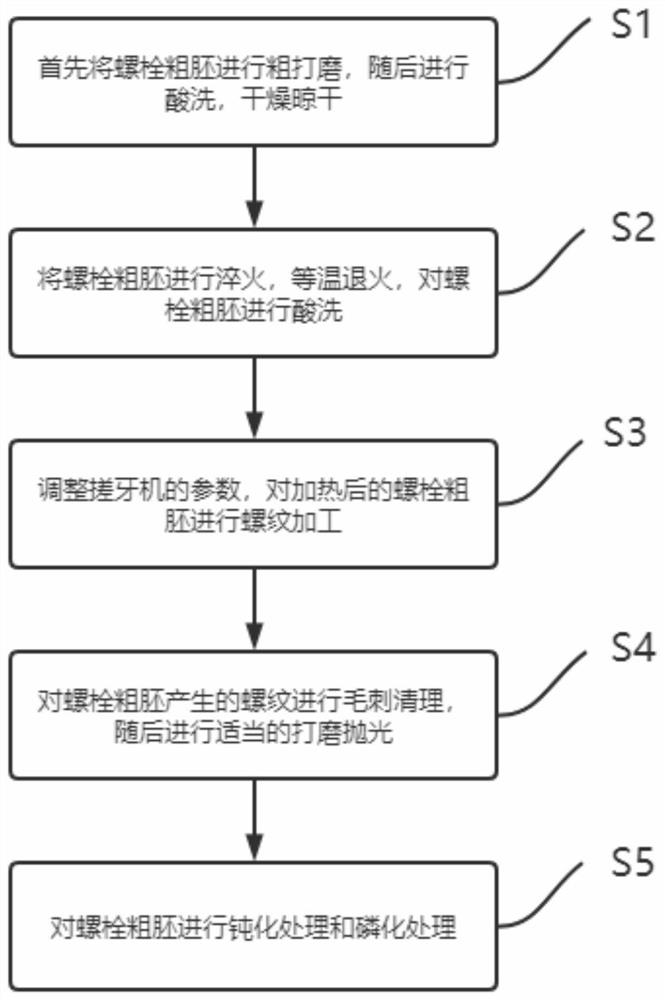

[0022] The present invention provides a technical solution: please refer to figure 1 , a production method for efficiently producing high-strength bolts, comprising the following steps:

[0023] Step 1. Firstly, the rough bolts are roughly ground, then pickled, and dried.

[0024] Step 2: Quenching the rough bolts, isothermal annealing, and pickling the rough bolts.

[0025] Step 3: Adjust the parameters of the thread rolling machine, and process the heated rough bolt blank.

[0026] Step 4: Deburring the threads produced by the rough bolts, and then performing proper grinding and polishing.

[0027] Step five, passivation treatment and phosphating treatment are performed on the rough bolt blank.

[0028] Specifically, according to the operation steps in the first step, the bolt blanks are casted, demoulded and cooled with high-quality molten iron.

[0029] Specifically, according to the operation steps in step 1, the components of the pickling solution used for pickling a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap