Extrusion die, polytetrafluoroethylene film and preparation method and application thereof

A polytetrafluoroethylene, extrusion die technology, applied in chemical instruments and methods, film, film technology and other directions, to achieve the effect of good air permeability, easy operation of the process, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

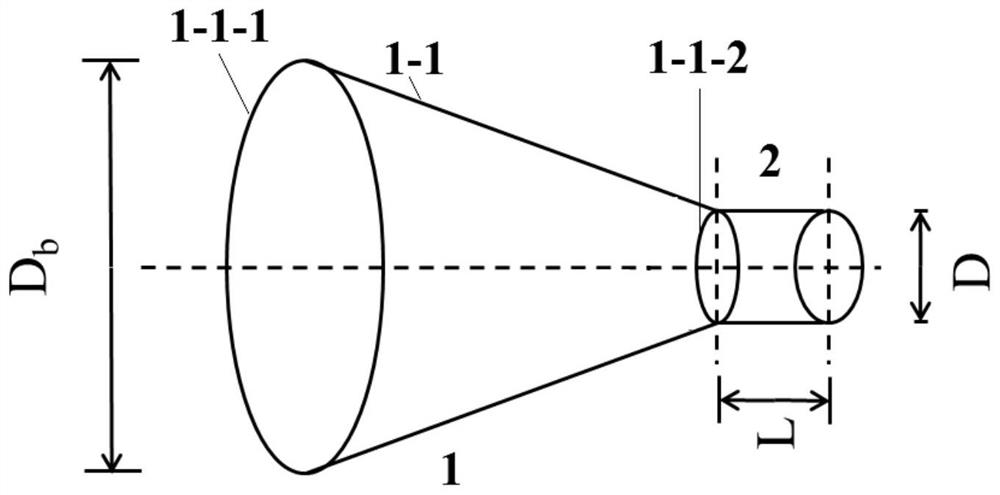

[0050] This embodiment provides an extrusion die, including a connected first shell 1 and a second shell 2,

[0051] Such as figure 1 As shown, the first housing 1 is provided with at least one cavity 1-1, and the cavity includes a material inlet 1-1-1 and a material outlet 1-1-2. After the material enters the first housing 1, it is extruded , discharged from the material outlet into the second housing 2, and at least two different roughnesses are set on the surface of the cavity in contact with the material. When the extrusion die is used to prepare polytetrafluoroethylene film, it can make the film have the advantages of strength, high filtration efficiency, and good air permeability. At the same time, the extrusion die has no special requirements for the processing technology of polytetrafluoroethylene film. There is no need to employ complicated processes.

[0052] Specifically, at least two different roughnesses are set on the surface of the cavity, and the roughness (R...

Embodiment 2

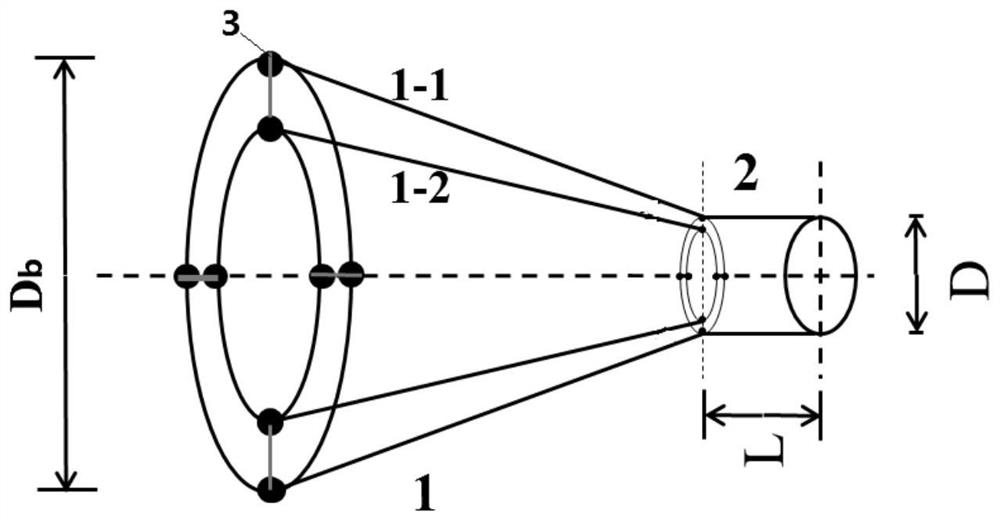

[0061] The present embodiment provides a kind of extruding mold of preparing polytetrafluoroethylene film, as Figure 3-5 shown, including,

[0062] The first housing is provided with a first cavity 1-1, a second cavity 1-2 and a third cavity 1-3, the first cavity, the second cavity and the third cavity are all of circular frustum structure, And the axis of the circular frustum structure is parallel to the horizontal plane; the inner surface a of the first cavity 1-1 is provided with a first area and a second area, the roughness of the first area is 50, the roughness of the second area is 0.025, and the first area It is surrounded by the first arc, the second arc, the first busbar and the second busbar, the second area is surrounded by the third arc, the fourth arc, the first busbar and the second busbar, and the first area The arc length is 1 / 2 of the circumference of the circle where it is located, that is, the frustum structure is divided into upper and lower parts along t...

Embodiment 3

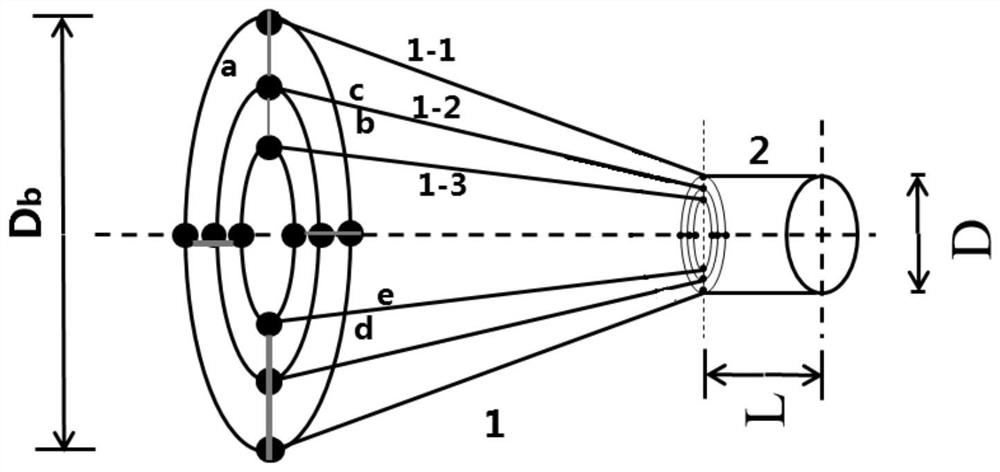

[0066] The present embodiment provides a kind of extruding mold for preparing polytetrafluoroethylene film, with image 3 ,include,

[0067] The first housing is provided with a first cavity 1-1, a second cavity 1-2 and a third cavity 1-3, the first cavity, the second cavity and the third cavity are all of circular frustum structure, And the axis of the circular frustum structure is parallel to the horizontal plane; the inner surface a of the first cavity 1-1 is provided with a first area and a second area, the roughness of the first area is 50, the roughness of the second area is 0.1, and the first area It is surrounded by the first arc, the second arc, the first busbar and the second busbar, the second area is surrounded by the third arc, the fourth arc, the first busbar and the second busbar, and the first area The arc length is 1 / 2 of the circumference of the circle where it is located, that is, the frustum structure is divided into upper and lower parts along the horizon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com