Leveling device for linear drainage ditch of bridge

A technology for leveling devices and drainage ditches, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in keeping the slope of the bridge deck consistent, non-adjustable, fixed height, etc., achieve structural stability, increase service life, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

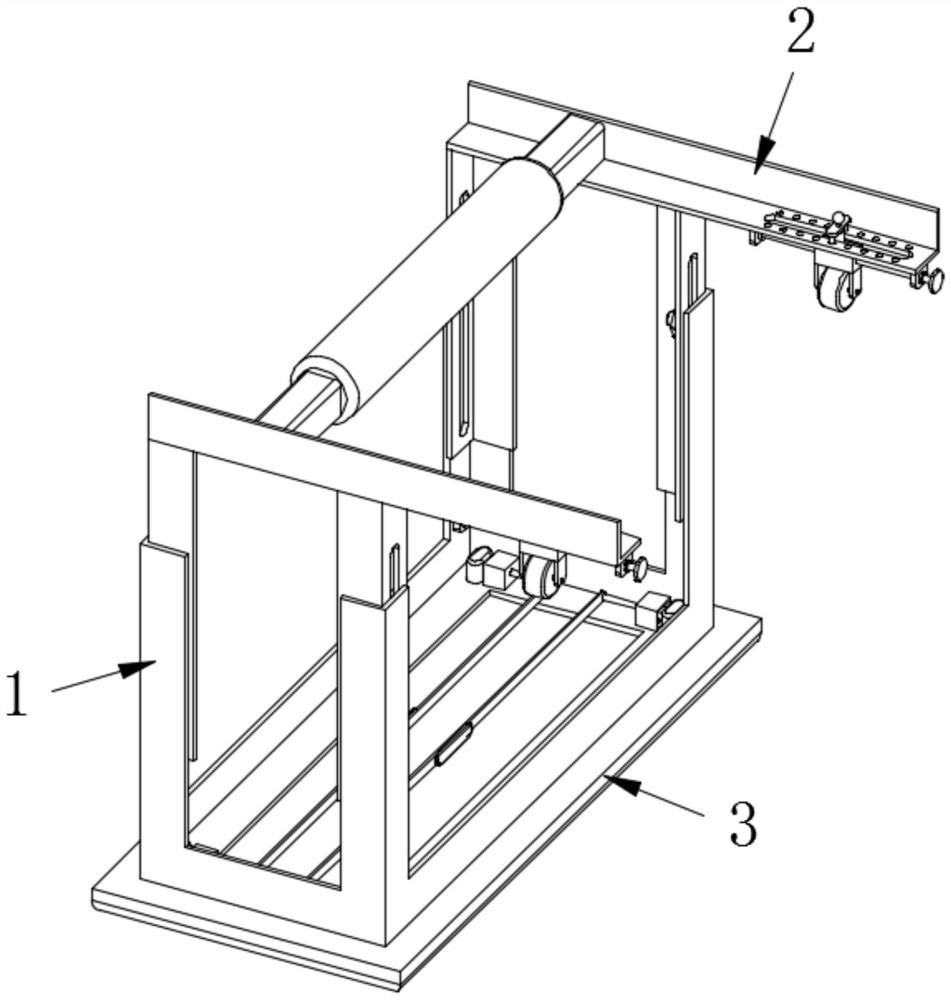

[0055] Such as Figure 1-9 As shown, a bridge linear drain leveling device according to an embodiment of the present invention includes a connecting mechanism 1, a guiding mechanism 2 installed on the top of the connecting mechanism 1, and a smoothing mechanism 3 installed on the bottom of the connecting mechanism 1 ;

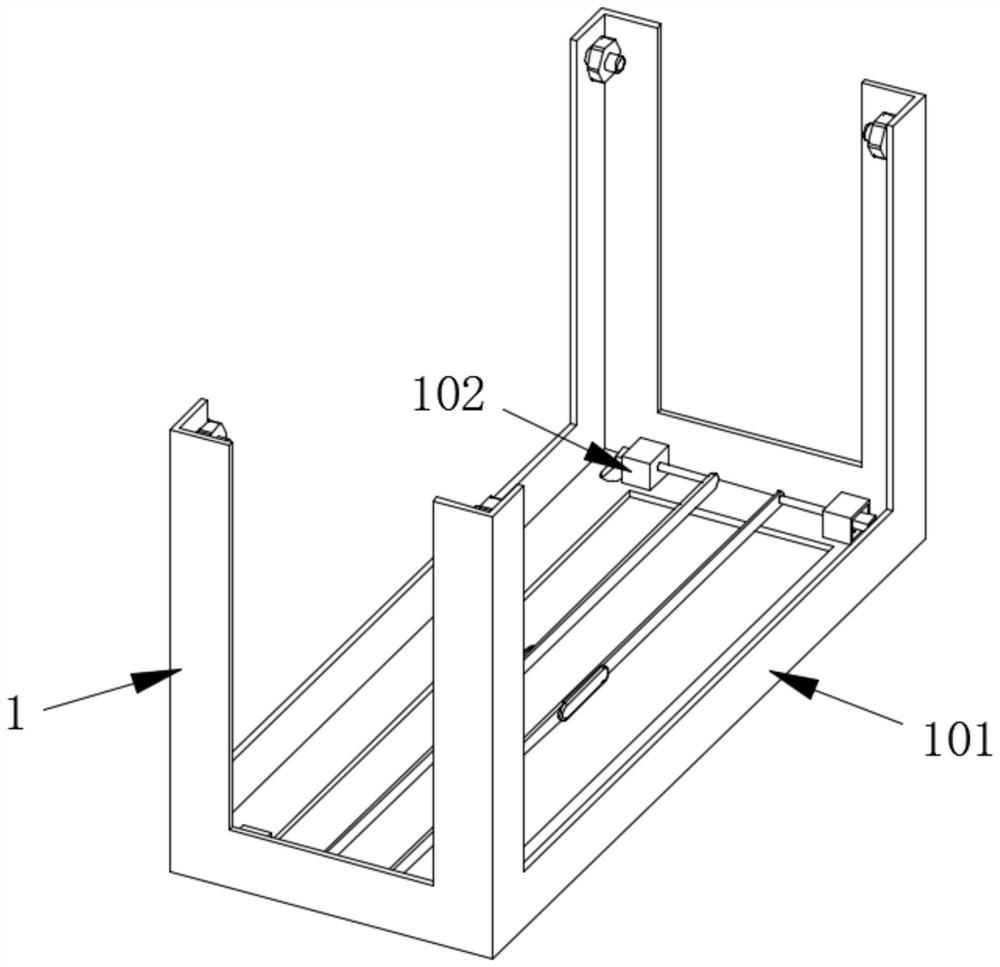

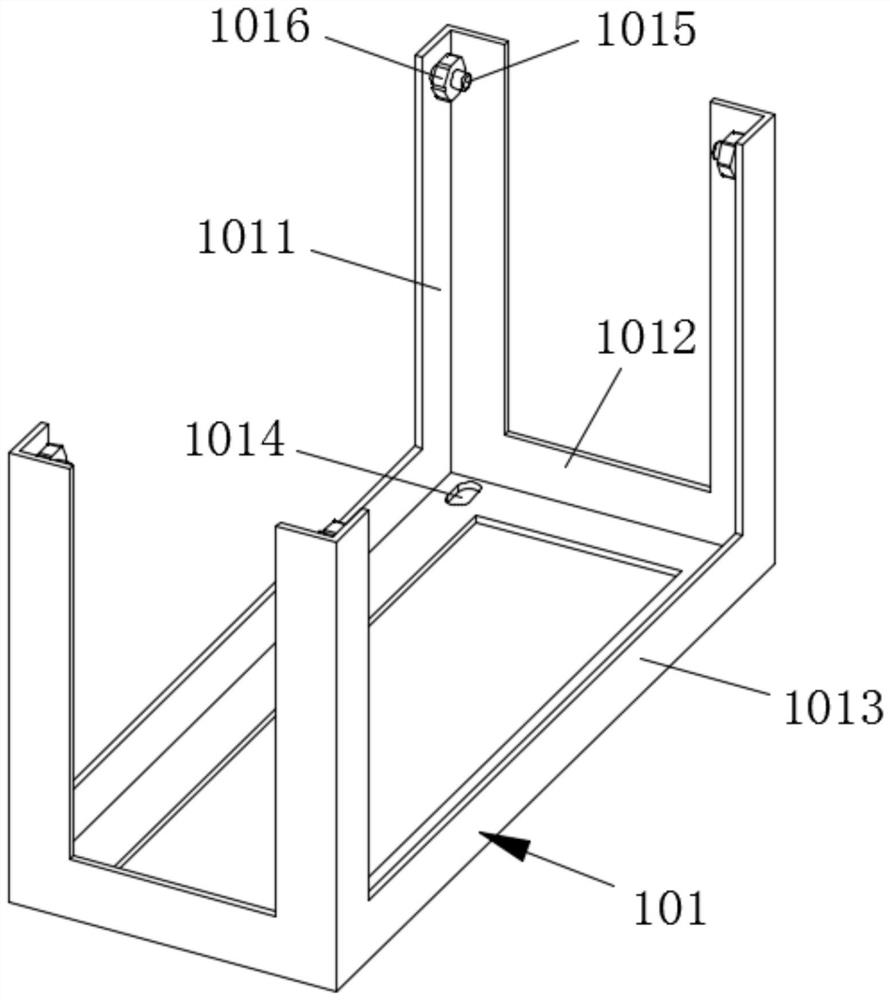

[0056] Wherein, the connection mechanism 1 is composed of a connection component 101 and two clamping components 102 symmetrically installed on the connection component 101;

[0057] Wherein, the connection assembly 101 includes four vertical angle steels 1011, and the two vertical angle steels 1011 on the same side are fixedly connected by a transverse angle steel 1012, and the two horizontal angle steels 1012 are fixedly connected with symmetrically arranged The two longitudinal angle steels 1013 are provided with two symmetrically arranged mounting holes 1014 on the two longitudinal angle steels 1013, and the sides of the vertical angle steels 1011 are fixe...

Embodiment 2

[0071] Such as Figure 1-9 As shown, the difference between this embodiment and Embodiment 1 is that a positioning assembly 2058 is installed on the top of the threaded sleeve 2054, and the positioning assembly 2058 includes a cylinder 20581 fixedly connected to the top of the threaded sleeve 2054, The bottom of the inner wall of the cylinder 20581 is fixedly connected with a positioning spring 20582, and the top of the positioning spring 20582 is fixedly connected with a cylinder 20583 slidingly connected with the cylinder 20581, and the top of the cylinder 20583 moves through the cylinder The body 20581 is set and extended to the top of the barrel 20581 and is fixedly connected with a mounting rod 20584 , and both sides of the bottom of the mounting rod 20584 are fixedly connected with a limit rod 20585 matching with the limit groove 207 .

[0072] By adopting the above technical solution, the adjusted guide wheel 2057 can be limited and fixed, thereby improving the stabilit...

Embodiment 3

[0074] Such as Figure 1-9 As shown, the difference between this embodiment and Embodiment 2 is that the positioning assembly 2058 also includes a pull handle 205841 fixedly connected to the top of the installation rod 20584, and the limit rod 20585 is set in an arc shape, so The sides of the block 10215 are set in an arc shape.

[0075] By adopting the above technical solution, it is not only convenient to pull the installation rod 20584, but also increases the convenience of the stop rod 20585 snapping into the stop slot 207, and improves the convenience of snapping the block 10215 into the slot 303.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com