Antibacterial polyamide yarn and preparation method thereof

A nylon yarn and nylon technology, which is applied in the field of nylon production, can solve the problem that other properties of nylon yarn are not improved, and achieve the effects of effective antibacterial effect, simple operation and improved mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

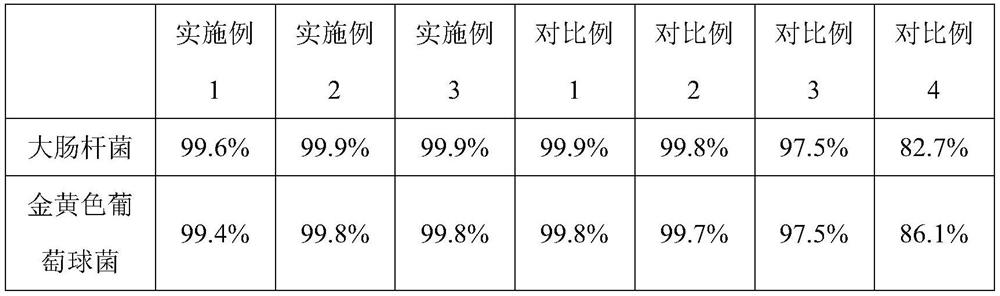

Examples

Embodiment 1

[0035] This embodiment provides a kind of nylon yarn, which is prepared according to the following steps:

[0036] (1) Take the following raw materials in parts by weight: 32 parts of nylon 6 slices, 48 parts of nylon 66 slices, 15 parts of polypropylene fibers, 1 part of antioxidant 1098, 2 parts of nano-titanium dioxide, 2 parts of silver-loaded silica, 1 part of silicon carbide, 0.4 part of vinyl bis stearamide, 0.2 part of stearamide; each raw material obtained by weighing is used in the following steps;

[0037] (2) uniformly mixing polypropylene fiber, antioxidant, nano-titanium dioxide, silver-loaded silica, and silicon carbide, and heating and melting to obtain the first molten body;

[0038] (3) Carry out the following pretreatment on nylon 6 slices and nylon 66 slices: soak nylon 6 slices and nylon 66 slices in a 15g / L sodium alkylbenzene sulfonate solution for treatment, take them out after 10 minutes of treatment, and wash them with deionized water. After drying...

Embodiment 2

[0044] This embodiment provides a kind of nylon yarn, which is prepared according to the following steps:

[0045] (1) Take the following raw materials in parts by weight: 24 parts of nylon 6 slices, 60 parts of nylon 66 slices, 12 parts of polypropylene fibers, 1.5 parts of antioxidant 1098, 3 parts of nano-titanium dioxide, 3 parts of silver-loaded silica, 1 part of silicon carbide, 0.6 part of vinyl bis stearamide, 0.2 part of stearamide; each raw material obtained by weighing is used in the following steps;

[0046] (2) uniformly mixing polypropylene fiber, antioxidant, nano-titanium dioxide, silver-loaded silica, and silicon carbide, and heating and melting to obtain the first molten body;

[0047] (3) Carry out the following pretreatment on nylon 6 slices and nylon 66 slices: soak nylon 6 slices and nylon 66 slices in a 15g / L sodium alkylbenzene sulfonate solution for treatment, take them out after 10 minutes of treatment, and wash them with deionized water. After dryin...

Embodiment 3

[0053] This embodiment provides a kind of nylon yarn, which is prepared according to the following steps:

[0054] (1) Take the following raw materials in parts by weight: 30 parts of nylon 6 slices, 60 parts of nylon 66 slices, 10 parts of polypropylene fiber, 1 part of antioxidant 1098, 1 part of nano-titanium dioxide, 5 parts of silver-loaded silica, 1.5 parts of silicon carbide, 1 part of vinyl bis stearamide, 0.5 part of stearamide; each raw material obtained by weighing is used in the following steps;

[0055] (2) uniformly mixing polypropylene fiber, antioxidant, nano-titanium dioxide, silver-loaded silica, and silicon carbide, and heating and melting to obtain the first molten body;

[0056] (3) Carry out the following pretreatment on nylon 6 slices and nylon 66 slices: soak nylon 6 slices and nylon 66 slices in a 15g / L sodium alkylbenzene sulfonate solution for treatment, take them out after 10 minutes of treatment, and wash them with deionized water. After drying, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com