Homogeneous mixed intelligent oil displacement system, preparation method thereof and corresponding oil displacement method

An intelligent and oil-displacing technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of high permeability, unblocking, large injection volume, large difference, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A homogeneous mixed intelligent oil displacement system, including polymers and additives, the concentration of polymers is 1500mg / L, the concentration of additives is 1500mg / L, and the polymers are 19 million parts produced by Daqing Refining and Chemical Company Hydrolyzed polyacrylamide is a commercially available product; the additive is obtained by mixing metal-organic polymer DYST-2 and phenolic DYFD-2 at a mass ratio of 1:1, and the injection system is injected into the oil reservoir at a temperature of 45°C.

[0054] The preparation method of the homogeneous mixing intelligent oil displacement system comprises adding additives into water, adding a polymer, and stirring for more than 1 hour to obtain a homogeneous mixing intelligent oil displacement system.

[0055] The oil displacement method using the homogeneous mixed intelligent oil displacement system comprises the following steps:

[0056] (1) Inject the homogeneous mixed intelligent oil displacement system...

Embodiment 2

[0060] A homogeneous mixed intelligent oil displacement system, the concentration of the polymer is 2500mg / L, the concentration of the additive is 1500mg / L, the polymer is 19 million partially hydrolyzed polyacrylamide produced by Daqing Refining and Chemical Company, the additive The metal-organic polymer DYST-2 and the phenolic DYFD-2 are mixed at a mass ratio of 1:1, and the injection system is injected into the oil reservoir at a temperature of 45°C.

[0061] The preparation method of the homogeneous mixing intelligent oil displacement system comprises adding additives into water, adding a polymer, and stirring for more than 1 hour to obtain a homogeneous mixing intelligent oil displacement system.

[0062] The oil displacement method using the homogeneous mixing intelligent oil displacement system is the same as that in Embodiment 1.

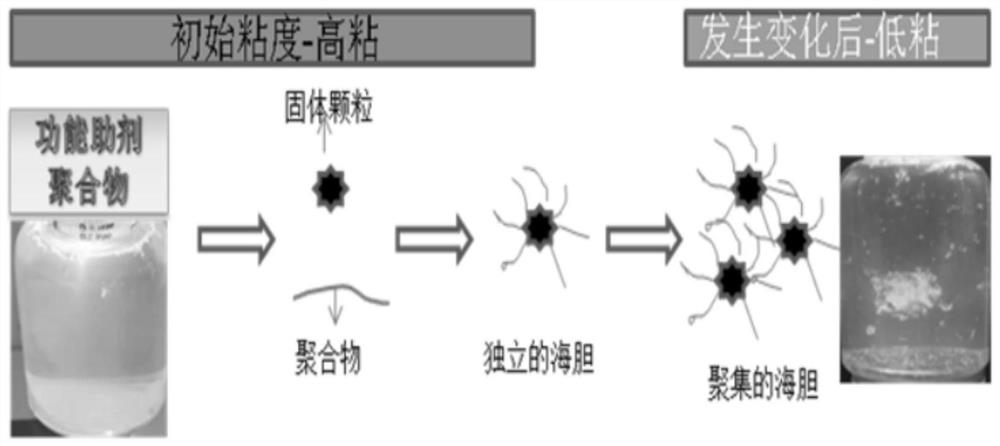

[0063] When the homogeneous mixed intelligent flooding system is injected into the oil reservoir, the viscosity first increases and then d...

Embodiment 3

[0065] A homogeneous mixed intelligent oil displacement system, the concentration of the polymer is 2000mg / L, the concentration of the auxiliary agent is 1500mg / L, the polymer is 19 million partially hydrolyzed polyacrylamide produced by Daqing Refining and Chemical Company, the auxiliary agent The metal-organic polymer DYST-2 and the phenolic DYFD-2 are mixed at a mass ratio of 1:1, and the injection system is injected into the oil reservoir at a temperature of 45°C.

[0066] According to the preparation method of the homogeneous mixing intelligent oil displacement system, the auxiliary agent is added into the water, then the polymer is added, and the mixture is stirred for more than 1 hour to obtain the homogeneous mixing intelligent oil displacement system.

[0067] Under the condition of high temperature and high salinity, the viscosity change of the homogeneous mixed intelligent flooding system was not measured, but a large number of solid particles appeared in the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com