MPP communication and power cable tube with high flame retardance and processing technology thereof

A processing technology and cable tube technology, which is applied in the fields of high flame retardancy MPP communication, power cable tube and its processing technology, can solve the problem of general flame retardancy, poor impact resistance, high friction between material melt and processing equipment, etc. problems, to achieve the effect of low low temperature embrittlement temperature, excellent low temperature impact resistance, and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials include by weight: 30 parts of propylene resin, 40 parts of ultra-high molecular weight polyethylene resin, 3 parts of EPDM rubber, 0.1 part of polyethylene wax, 4 parts of magnesium hydroxide, 2 parts of calcium powder, 2 parts of clay and Pigment 0.1 part.

[0028] In the embodiment of the present invention, the Mooney viscosity of the EPDM rubber is 30.

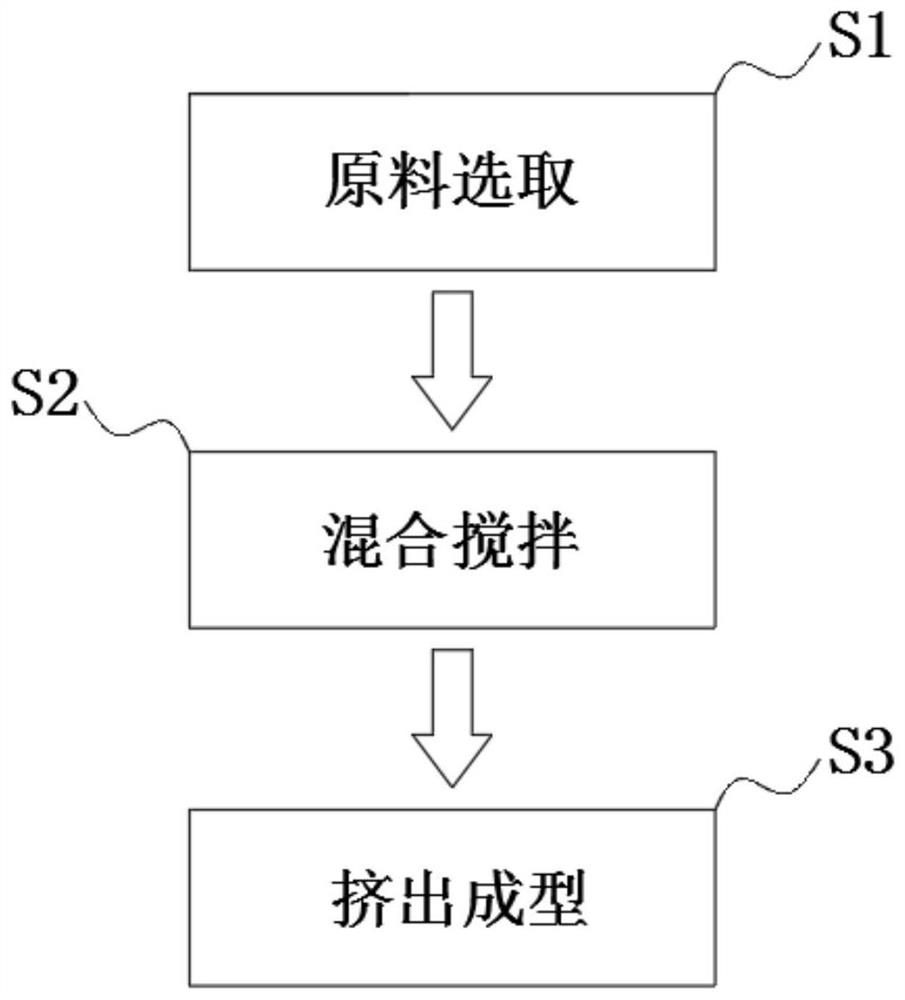

[0029] The invention also discloses a processing technology of a high flame-retardant MPP communication and power cable tube, which specifically includes the following steps:

[0030] S1. Raw material selection: Weigh propylene resin, ultra-high molecular weight polyethylene resin, EPDM rubber, polyethylene wax, magnesium hydroxide, calcium powder, pottery clay and pigment according to the weight ratio;

[0031] S2. Mixing and stirring: Add the propylene resin, ultra-high molecular weight polyethylene resin and polyethylene wax weighed in S1 into the mixer and mix and stir evenly. Stir with a stir...

Embodiment 2

[0034] The raw materials include by weight: 35 parts of propylene resin, 45 parts of ultra-high molecular weight polyethylene resin, 4 parts of EPDM rubber, 0.2 part of polyethylene wax, 5 parts of magnesium hydroxide, 3 parts of calcium powder, 3 parts of clay and 0.2 parts of pigment.

[0035] In the embodiment of the present invention, the Mooney viscosity of the EPDM rubber is 45.

[0036] The invention also discloses a processing technology of a high flame-retardant MPP communication and power cable tube, which specifically includes the following steps:

[0037] S1. Raw material selection: Weigh propylene resin, ultra-high molecular weight polyethylene resin, EPDM rubber, polyethylene wax, magnesium hydroxide, calcium powder, pottery clay and pigment according to the weight ratio;

[0038] S2. Mixing and stirring: Add the propylene resin, ultra-high molecular weight polyethylene resin and polyethylene wax weighed in S1 into the mixer and mix and stir evenly. Stir with a ...

Embodiment 3

[0041] The raw materials include by weight: 40 parts of propylene resin, 50 parts of ultra-high molecular weight polyethylene resin, 5 parts of EPDM rubber, 0.3 parts of polyethylene wax, 6 parts of magnesium hydroxide, 4 parts of calcium powder, 4 parts of pottery clay and 0.3 parts of pigment.

[0042] In the embodiment of the present invention, the Mooney viscosity of the EPDM rubber is 60.

[0043]The invention also discloses a processing technology for high flame-retardant MPP communication and electric power cable tubes, which specifically includes the following steps:

[0044] S1. Raw material selection: Weigh propylene resin, ultra-high molecular weight polyethylene resin, EPDM rubber, polyethylene wax, magnesium hydroxide, calcium powder, pottery clay and pigment according to the weight ratio;

[0045] S2. Mixing and stirring: Add the propylene resin, ultra-high molecular weight polyethylene resin and polyethylene wax weighed in S1 into the mixer and mix and stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com