Device and process for producing 1-octylene by ethylene selective oligomerization

A selectivity and ethylene technology, applied in the direction of hydrocarbons, hydrocarbons, catalysts, etc., can solve the problems of low reaction temperature, removal, large heat release, etc., to achieve enhanced mass transfer, reduced costs, and increased gas holdup Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

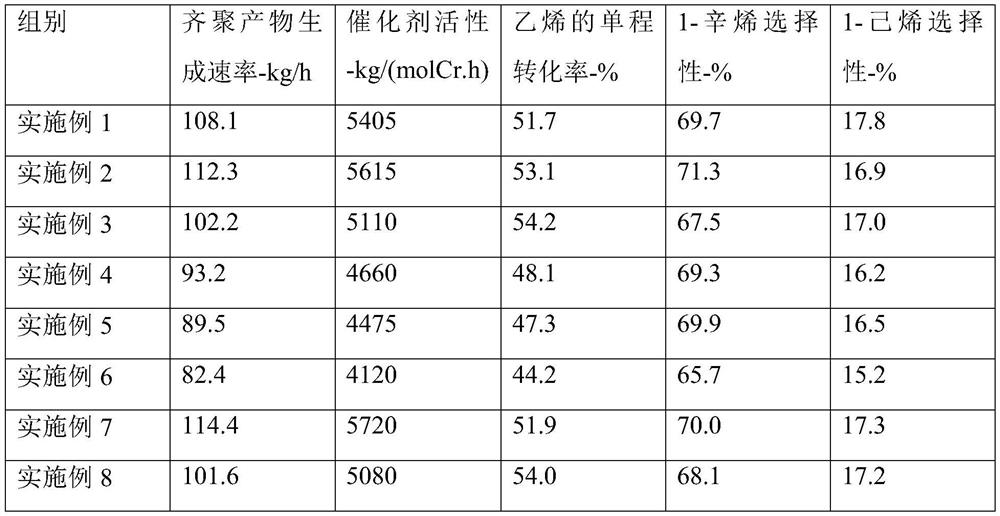

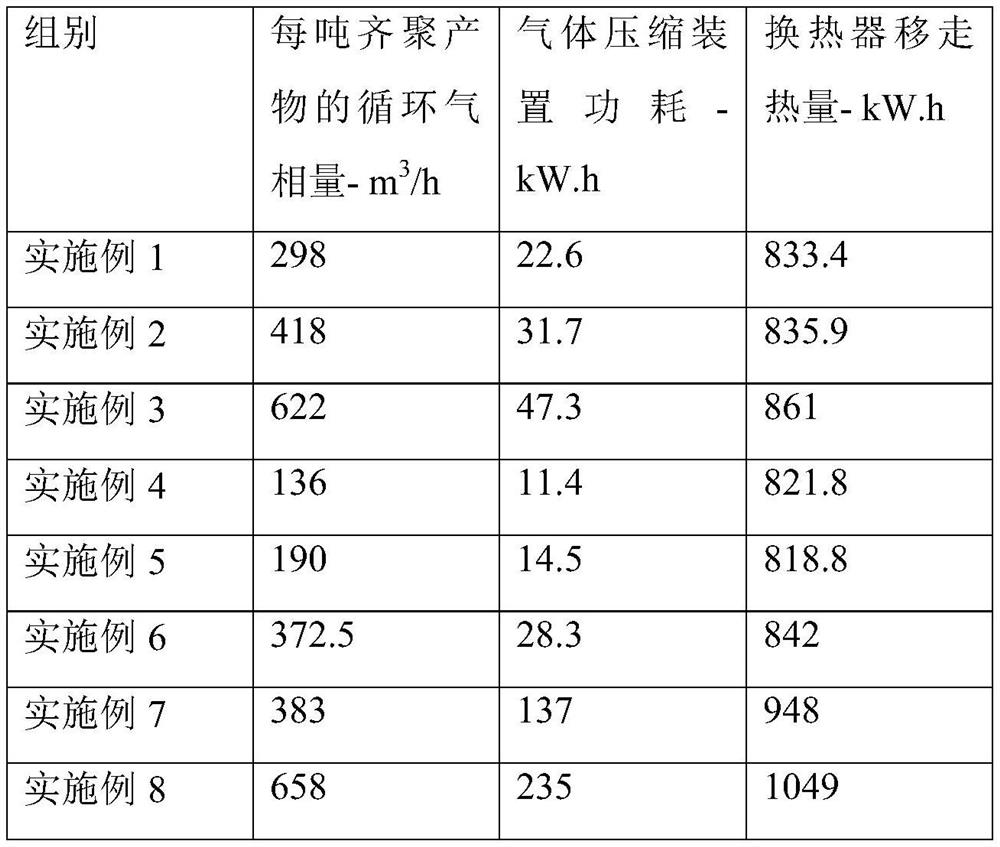

Examples

Embodiment 1

[0096] Such as figure 1 As shown, the present embodiment provides a device for the selective oligomerization of ethylene to produce 1-octene, which consists of the following parts:

[0097] The oligomerization reactor 1 is a tank reactor with a volume of 300L, which is equipped with a gas phase distributor 2, a liquid phase distributor 3 and a reaction gas distributor 4, and an overflow is provided on the side wall of the oligomerization reactor 1. In the oligomerization reactor 1, the volume of the space below the overflow port accounts for 65% of the total volume. The bottom of the oligomerization reactor 1 is provided with a number of feed ports, and the liquid reaction materials are passed into the Qi by external feed pipelines. In the polymerization reactor 1, the gas material enters the oligomerization reactor 1 through the reaction gas distributor 4, and the top of the oligomerization reactor 1 is provided with a gas circulation outlet to connect the circulation pipelin...

Embodiment 2

[0111] The present embodiment provides a kind of technology of producing 1-octene, adopts the device that embodiment 1 provides, and processing step is identical with embodiment 1, and difference is only: solvent is replaced by methylcyclohexane (feed speed 20kg / h, containing methylcyclohexane used for preparing the catalyst) and isobutane (feed speed 80kg / h).

Embodiment 3

[0113] The present embodiment provides a kind of technique of producing 1-octene, adopts the device that embodiment 1 provides, and process step is identical with embodiment 1, and difference is only: solvent is replaced by methylcyclohexane (feed speed 100kg / h, containing methylcyclohexane used to prepare the catalyst).

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com