Organic light emitting device with low refractive capping layer

A technology for organic light-emitting devices and covering layers, which is applied to organic light-emitting devices, organic light-emitting device parameters, organic semiconductor devices, etc. The effect of current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 2

[0061] On the glass substrate, the covering layer compounds 1 and 2 for realizing the organic light-emitting device of the present invention were respectively deposited for 60-100 nm to measure the refractive index.

[0062] Quartz glass / organic (60~100nm)

experiment example 1

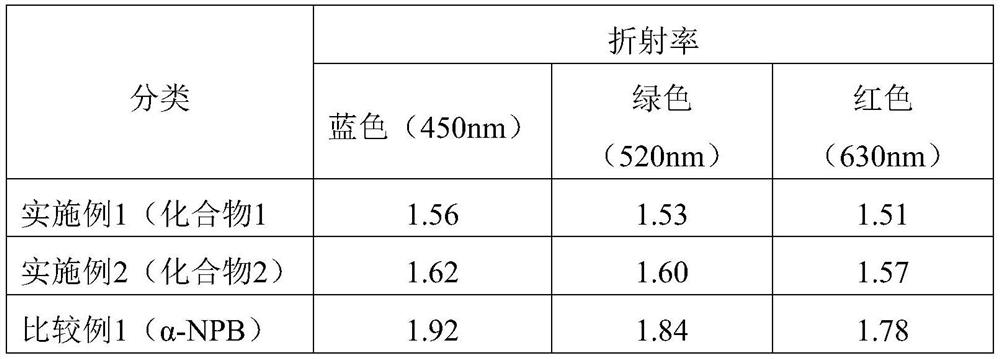

[0065] Experimental Example 1: Optical Characteristics of Experimental Examples 1 to 2

[0066] The refractive index of the substrate manufactured according to the above-mentioned examples was measured by ellipsometry (Ellipsometry, Elli-SE). The refractive index was measured in each wavelength region of blue (450 nm), green (520 nm), and red (630 nm), and the results are shown in Table 1 below.

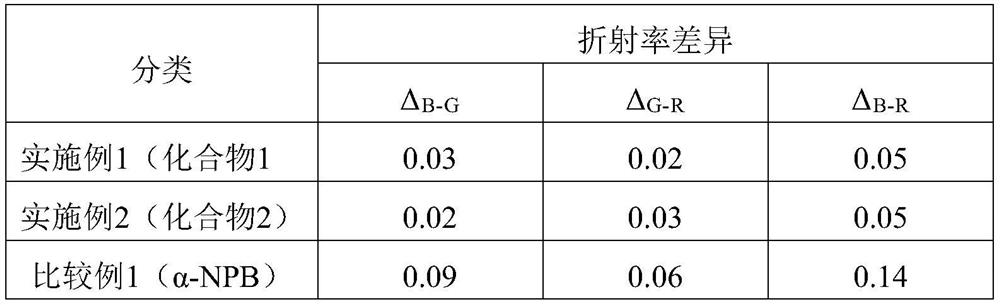

[0067] And, the refractive index difference (Δ B-G : difference between the refractive index of the blue (450nm) wavelength region and the refractive index of the green (520nm) wavelength region; Δ G-R : The difference between the refractive index in the green (520nm) wavelength region and the refractive index in the red (630nm) wavelength region; Δ B-R : the difference between the refractive index in the blue (450nm) wavelength region and the refractive index in the red (630nm) wavelength region), and is shown in Table 2 below.

[0068] Finally, the refractive indices in the wave...

Embodiment 3 to 4

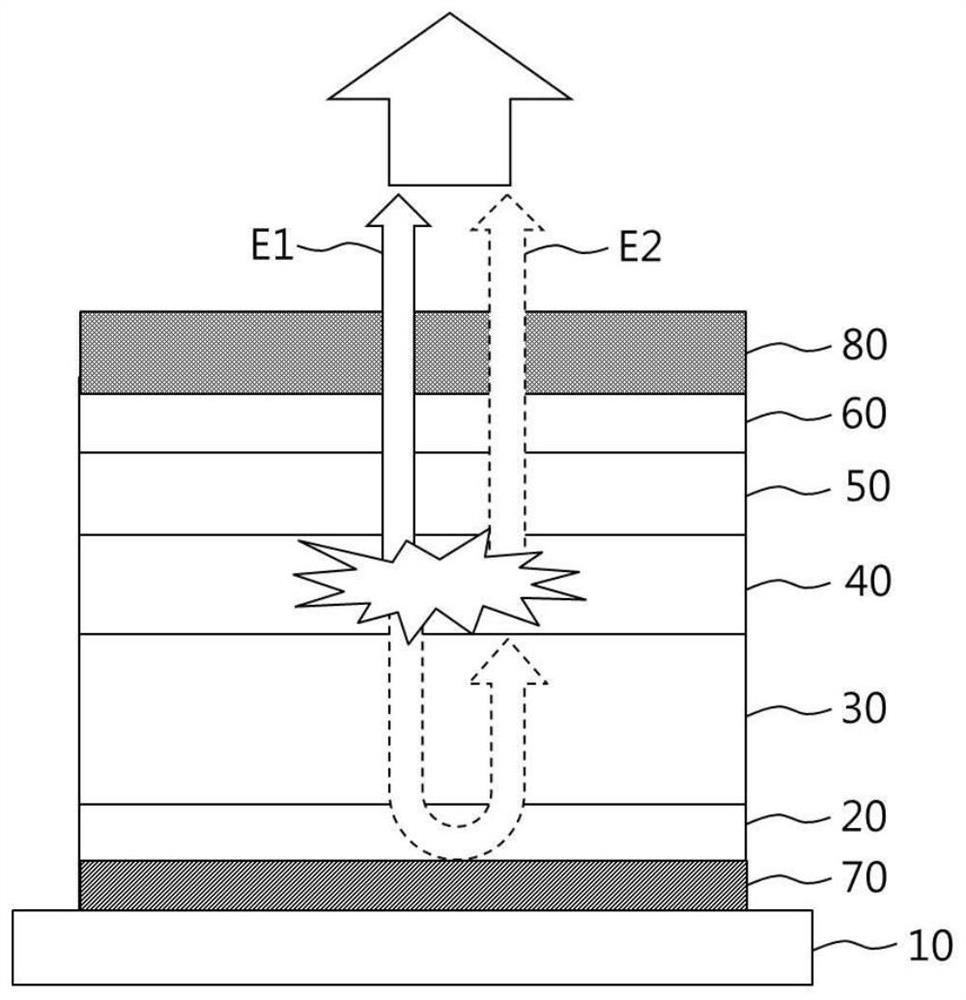

[0080] An organic light-emitting device having the following structure having a capping layer satisfying the specified conditions of the present invention was manufactured, and light-emitting characteristics including light-emitting efficiency were measured.

[0081] Ag / ITO / hole injection layer (HAT-CN, 5nm) / hole transport layer (TAPC, 100nm) / electron blocking layer (TCTA, 10nm) / light emitting layer (20nm) / electron transport layer 201 (Liq, 30nm) / LiF(1nm) / Mg:Ag(15nm) / Cover layer(70nm)

[0082] In order to form a hole injection layer on an Ag-containing ITO transparent electrode on a glass substrate, a HAT-CN film was formed to a thickness of 5 nm, and then a TAPC film was formed to a thickness of 100 nm as a hole transport layer. A TCTA film was formed with a thickness of 10 nm as an electron blocking layer. And, a light-emitting layer was co-deposited at 20 nm using BH1 as a host compound and BD1 as a dopant compound. Further, an electron transport layer (doped with the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peak wavelength | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com