Pattern splicing method for maskless laser high-precision scanning

A high-precision, mask-less technology, used in optics, optomechanical equipment, microlithography exposure equipment, etc. The effect of high performance, meeting the requirements of high precision and reducing distortion index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

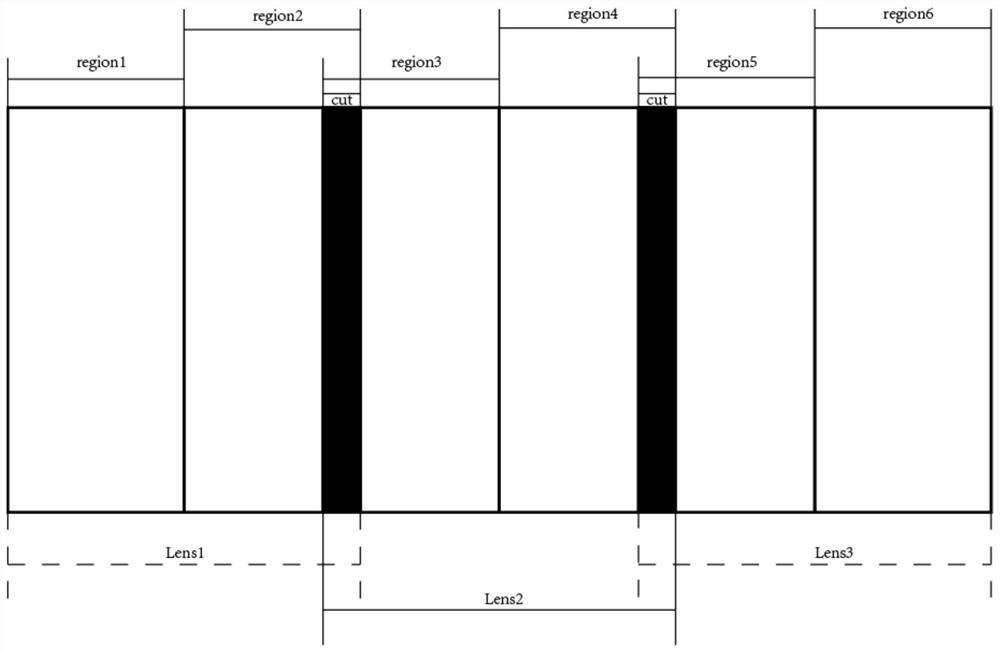

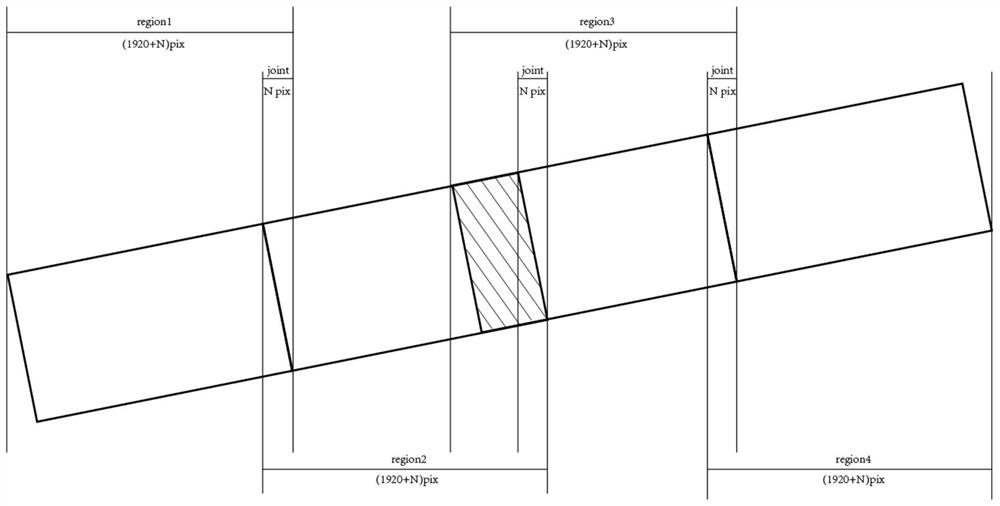

[0020] In order to effectively improve the splicing effect between exposure areas and meet the industrial needs of high precision and high resolution, the pattern splicing method for maskless laser high-precision scanning of the present invention specifically calibrates the DMD to Determine the angle and corresponding position of any lens corresponding to the DMD;

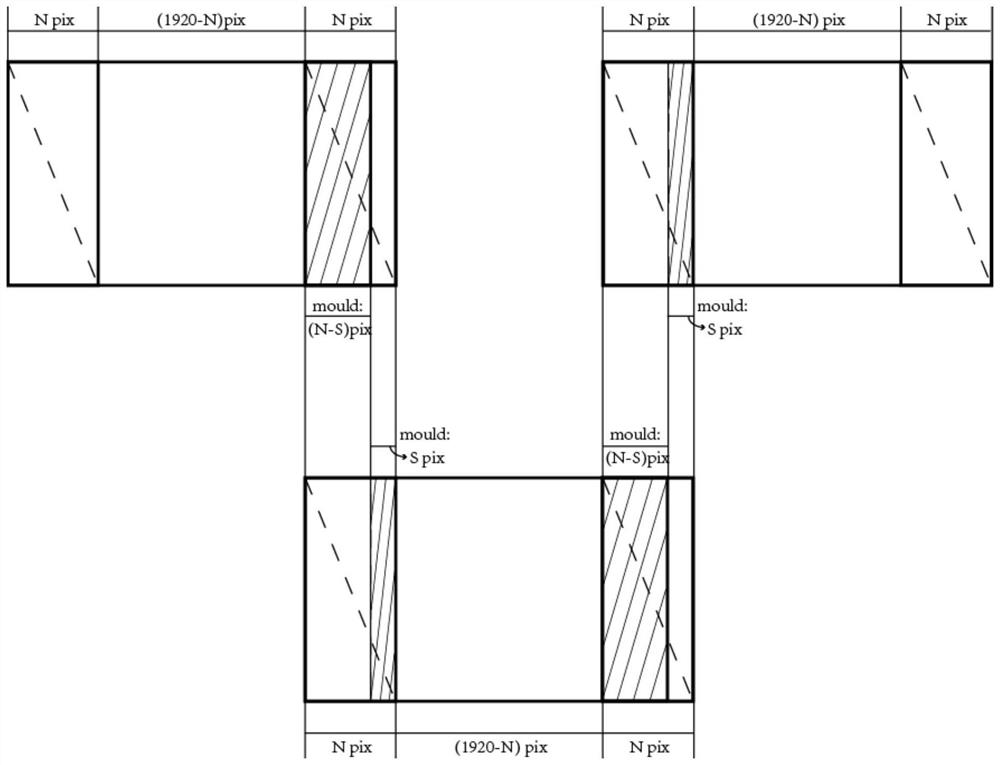

[0021] For any shot, determine the triangle stitching area in the shot formed by the lens projection according to the angle of the shot, and the triangle stitching area in the shot includes the positive exposure triangle stitching area formed in the positive exposure area and the triangle stitching area formed in the The anti-exposure triangle stitching area in the lens in the reverse exposure area, the positive exposure triangle stitching area in the lens and the reverse exposure triangle stitching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com