Impact testing device for impact-resistant gypsum plaster board

A paper-faced gypsum board, impact testing technology, applied in the direction of using a single impact force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of low testing efficiency, time-consuming and laborious testing process, etc., and achieve the effect of fast and uninterrupted testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

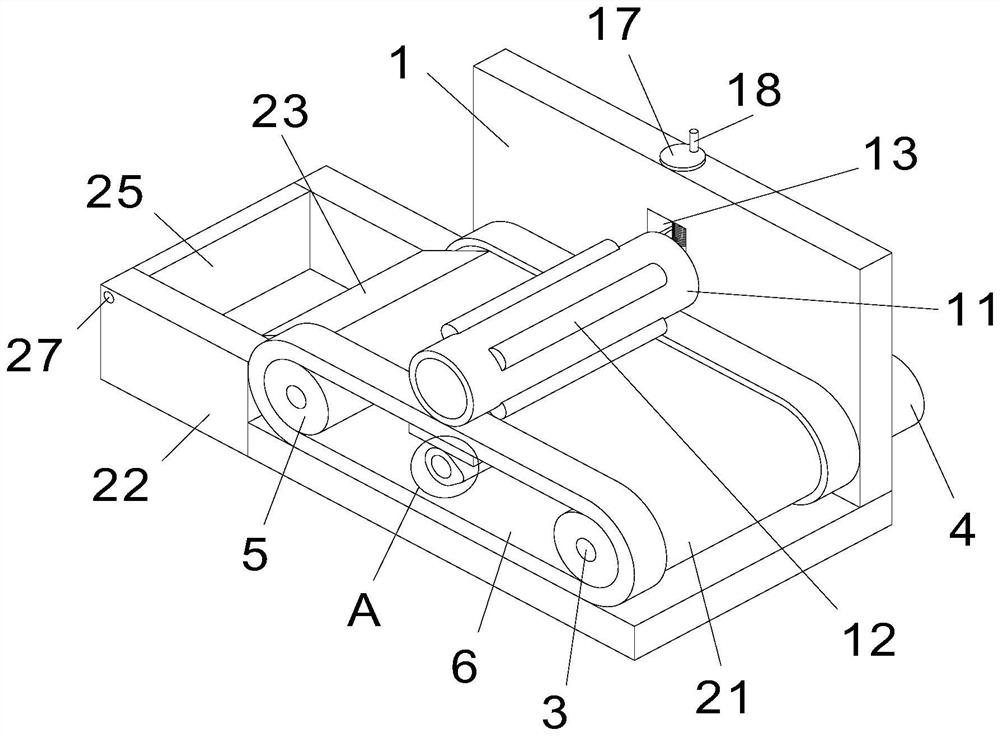

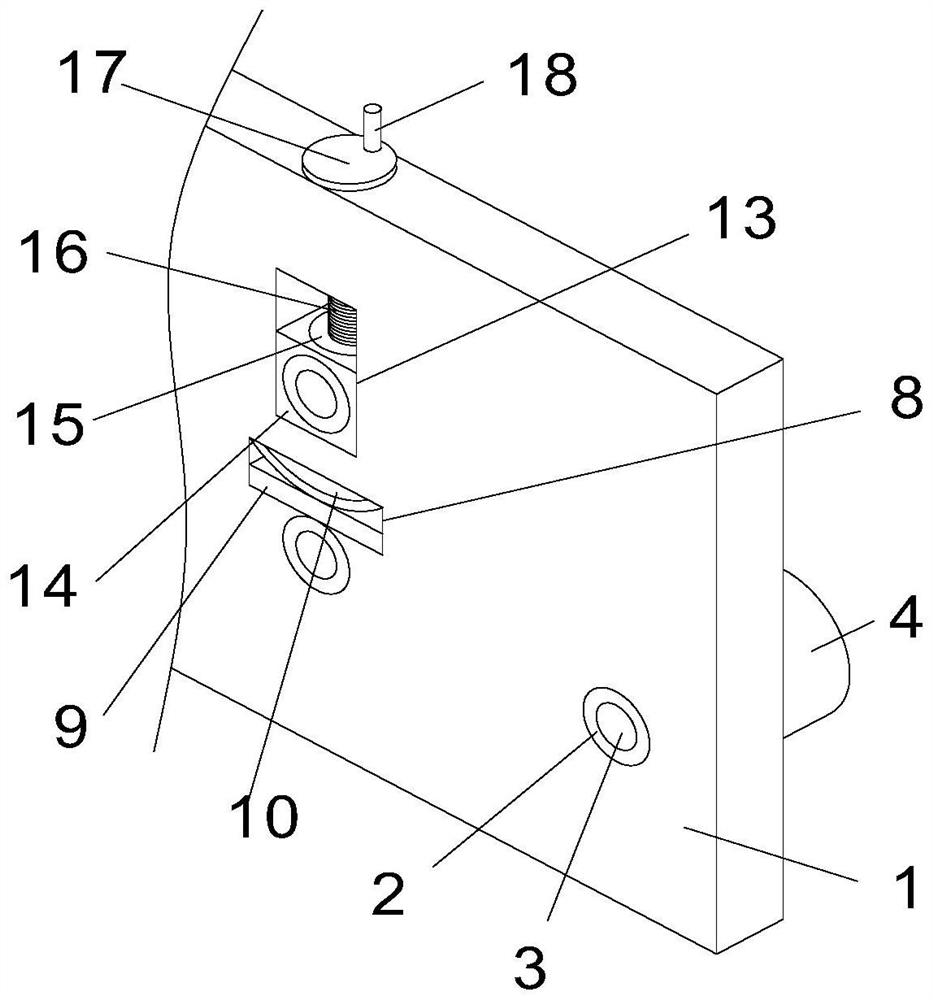

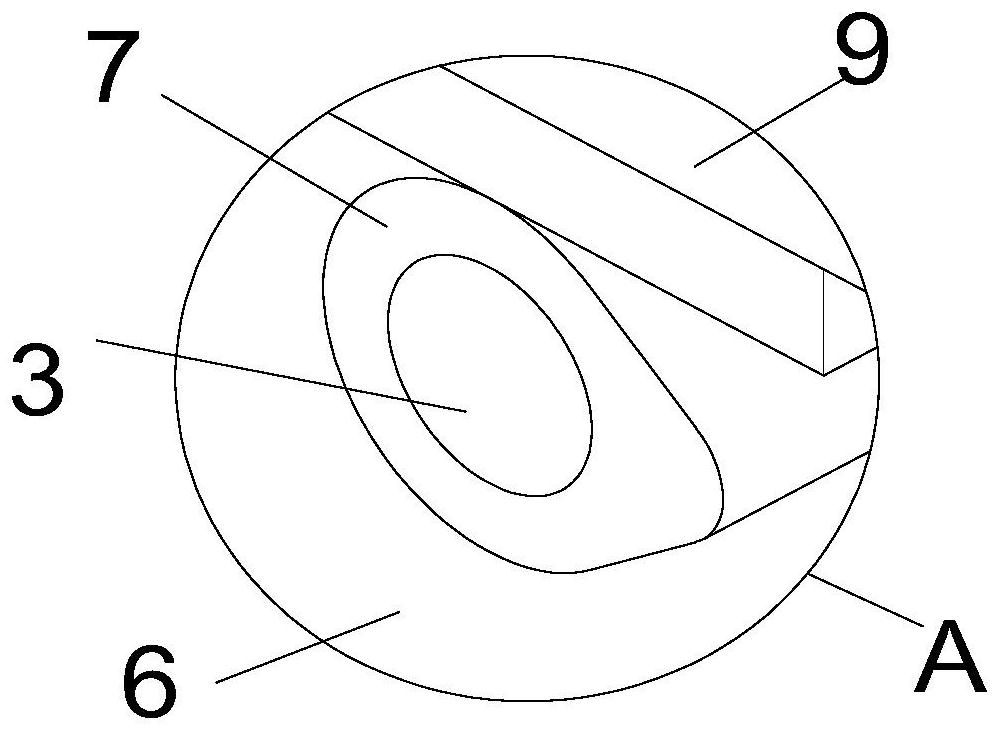

[0031] Embodiment: a kind of impact test device for impact-resistant plasterboard, such as figure 1 - Figure 5As shown, the base 1 is included, and the base 1 is a plate with an "L"-shaped structure. The front side wall of the base 1 is inlaid with four installation bearings 2, and the three installation bearings 2 on the lower installation shaft are inlaid and installed on the base 1. Above, the installation bearing 2 is a ring-shaped structure, the installation shaft 3 is fixedly installed on the inner ring of the installation bearing 2, the installation shaft 3 is a cylindrical structure, and the position corresponding to the installation shaft 3 is fixedly installed on the rear side wall of the base 1. The motor 4, the output end of the drive motor 4 is fixedly connected to the rear side wall of the installation shaft 3, and the installation shaft 3 on the left side and the right side is fixedly sleeved with the installation roller 5, and the installation roller 5 is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com