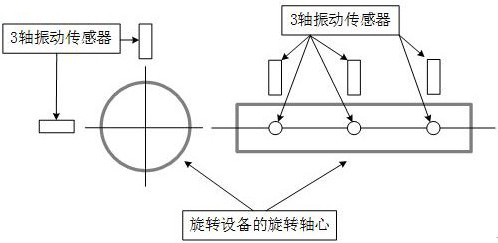

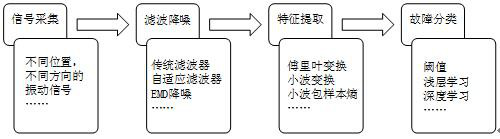

Vibration signal acquisition and processing method for rotating equipment fault source tracing

A vibration signal and processing method technology, applied in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of insufficient data, low data sampling frequency, low frequency response, etc., to increase the amount of data and enrich the sensor. information and the effect of improving the accuracy of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention realizes the classification of fault signals through the above-mentioned technical scheme, and the method has a complete flow of signal collection and processing. In order to enable those skilled in the art to better understand a vibration signal acquisition and processing method applied to the tracing of fault sources of rotating electromechanical equipment proposed by the present invention, the method mentioned in the invention will be specifically implemented below in conjunction with the drawings of the description description of.

[0024] Step 1: The vibration acceleration signal is collected by an analog vibration sensor using industrial-grade MEMS technology. The sensor end is equipped with an AD conversion module and a digital processor, and the signal is processed at the sensor end.

[0025] In an embodiment, the signal processing in step 1 includes analog signal processing and digital signal processing.

[0026] The analog signal process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com